Wool mattress set and manufacturing and renovating method thereof

A mattress and wool technology, applied in the field of wool mattresses, can solve the problems of high price and complicated composite structure manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

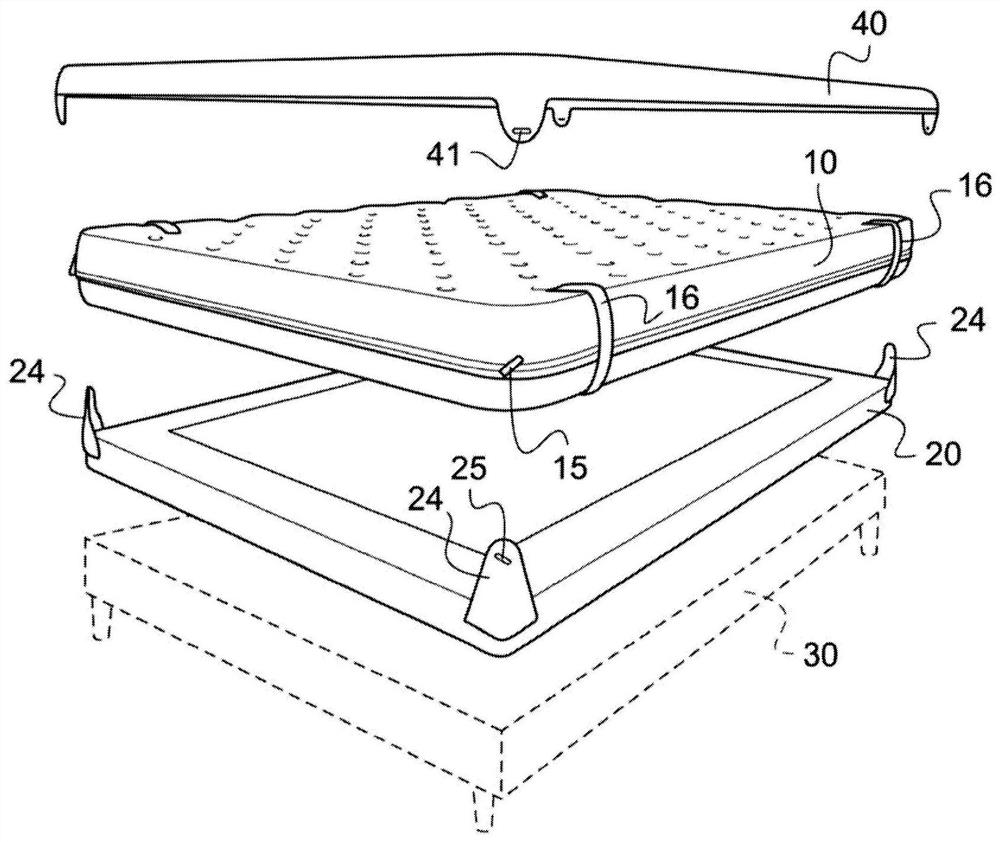

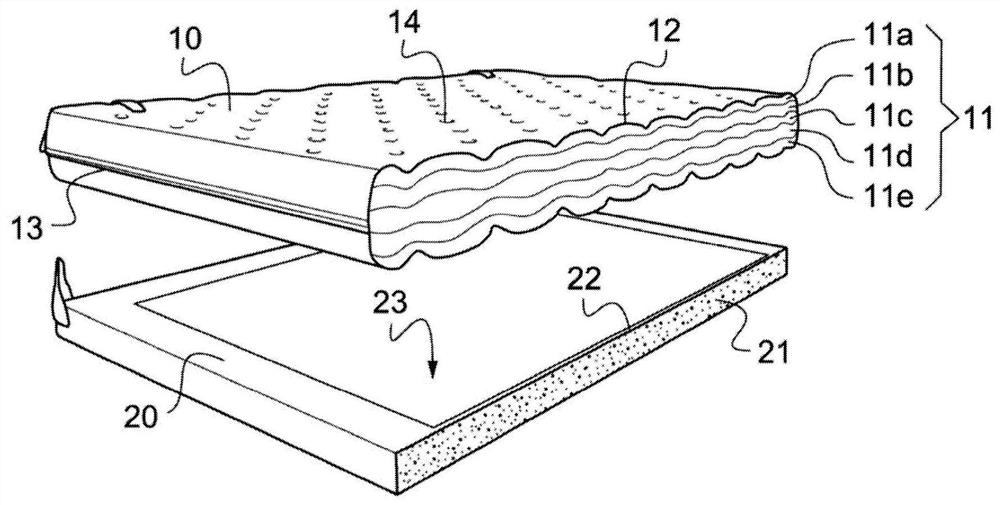

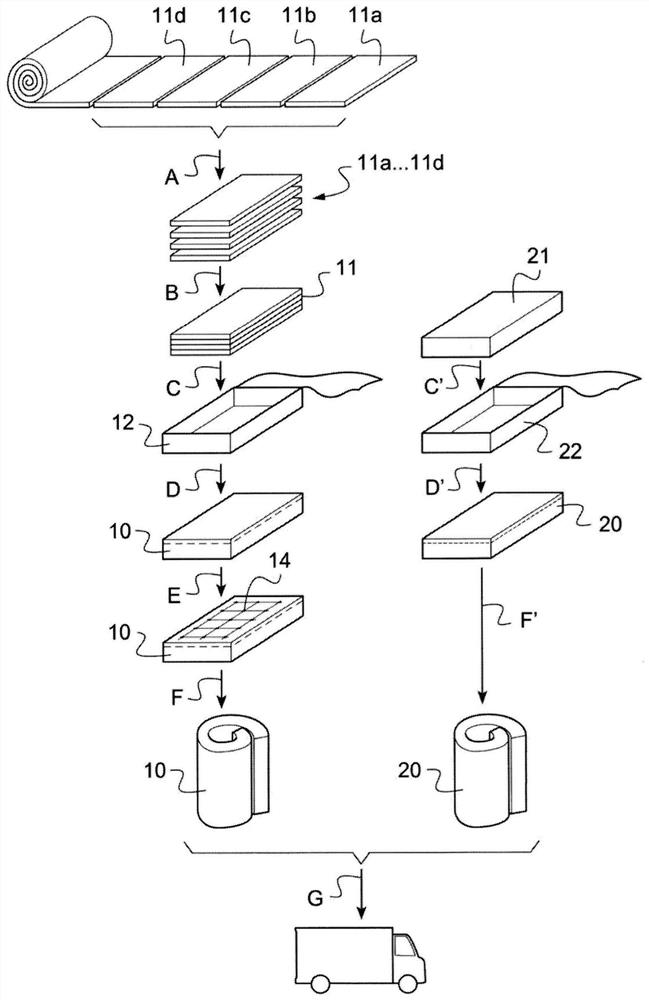

[0050] like figure 1 and figure 2As shown, the mattress set according to the invention basically comprises a receiving mattress 10 resting on a base mattress 20 . The receiving mattress 10 and the base mattress 20 are independent and separable from each other, and the receiving mattress 10 rests freely on the base mattress 20 . Advantageously, mattresses 10 and / or 20 are reversible mattresses.

[0051] The set of two mattresses 10, 20 is generally intended to rest on a bed frame 30 (the bed frame 30 is not part of the invention). Furthermore, the fitted sheet 40 advantageously covers the upper surface of the receiving mattress 10, in contact with the user, thereby protecting the mattress in this position.

[0052] The invention is characterized in that the receiving mattress 10 is a mattress comprising a wool filling 11 and the base mattress 20 is a mattress comprising a foam filling 21 .

[0053] The wool filling 11 receiving the mattress 10 is formed by a stack of super...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap