Method of enhancing clear field phase shift masks with border regions around phase 0 and phase 180 regions

A boundary region and phase region technology, applied in the field of patterning, can solve problems such as complex patterning of binary masks and limited manufacturing boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

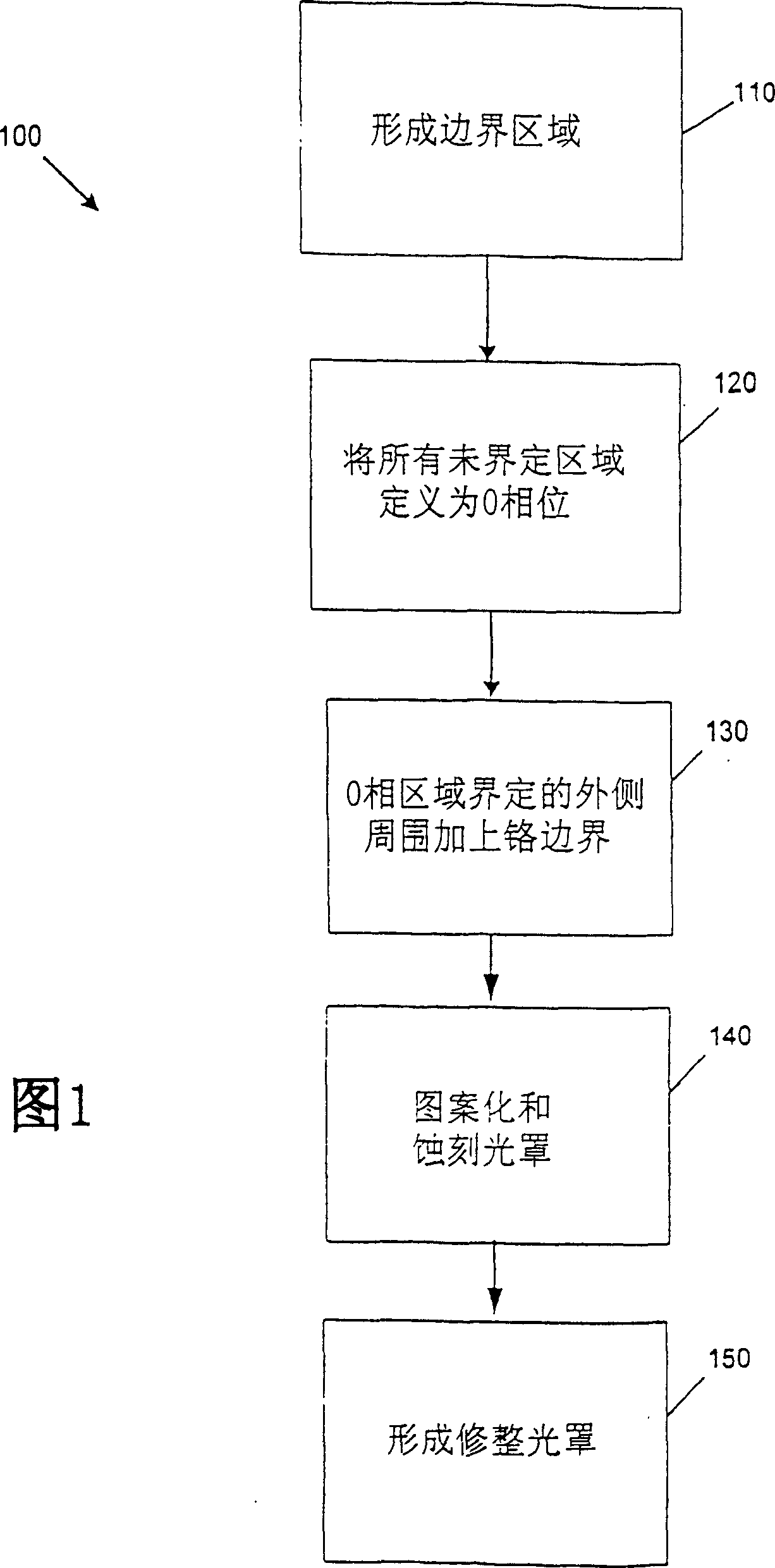

[0029] FIG. 1 shows a flowchart 100 describing example steps for forming or designing a phase shift mask (PSM) and a field or trim mask. A set of previously defined 0-phase regions or 180-phase regions on the phase mask can help identify critical polysilicon regions. These 0-phase regions or 180-phase regions can be created by hand, by using existing software programs, or by creating an optimal program to define these regions.

[0030] At step 110 , a chromium border region is formed on the phase mask outside of the 180 phase region edge of the previously defined 180 phase region that does not define the final polysilicon pattern. The chromium border area can be defined by hand drawing or by using a computer software program. The chromium border region has the advantage of allowing easy inspection of the mask and patterning the phase etching step of making the mask. At step 120, all undefined regions (final polysilicon pattern, or 180 phase regions, or chromium border region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com