Vibrating device of conicaster crystallizer

A technology of crystallizer vibration and continuous casting machine, which is applied in the field of metallurgical machinery, can solve problems such as unstable movement, and achieve the effect of no maintenance work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

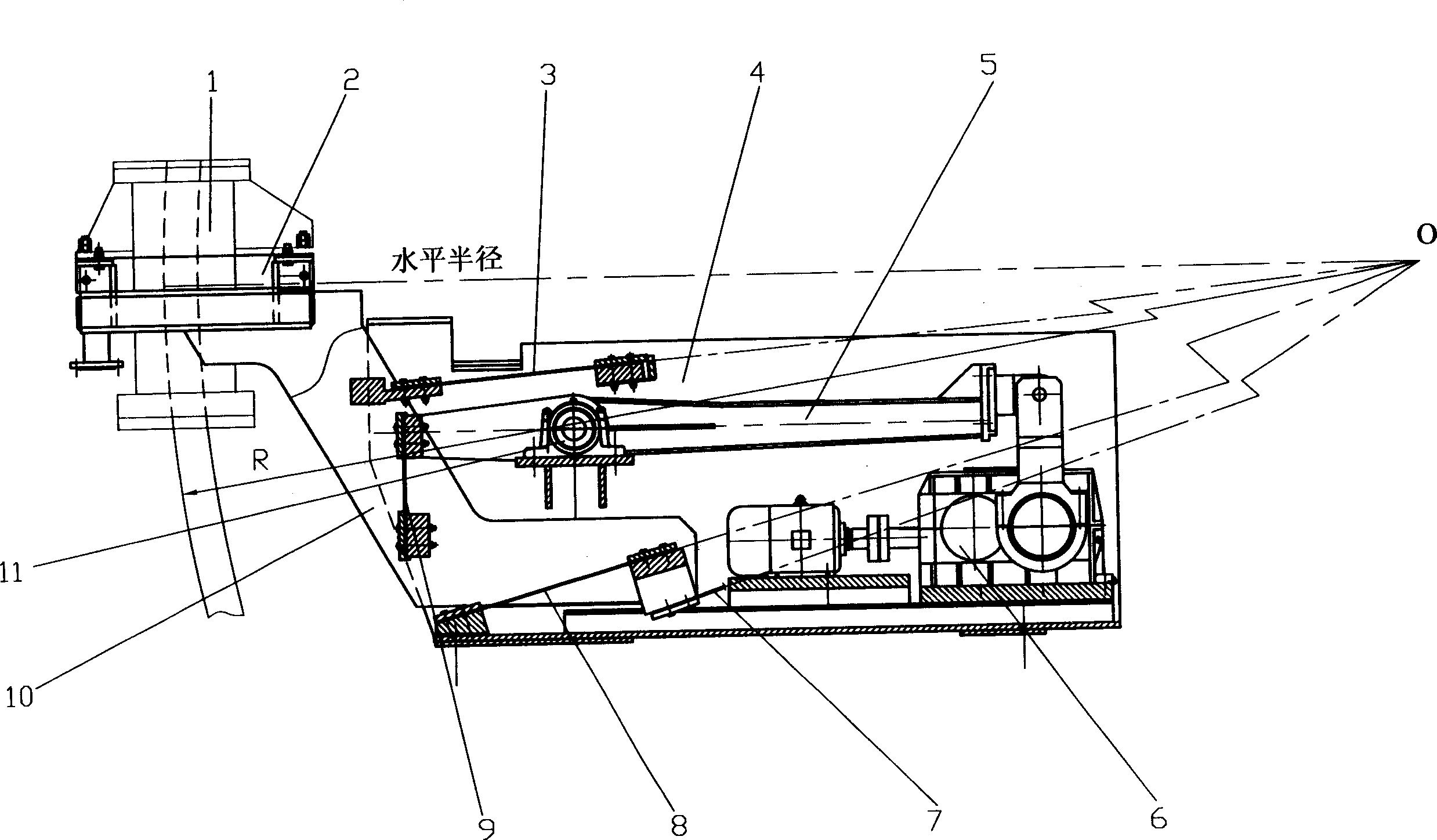

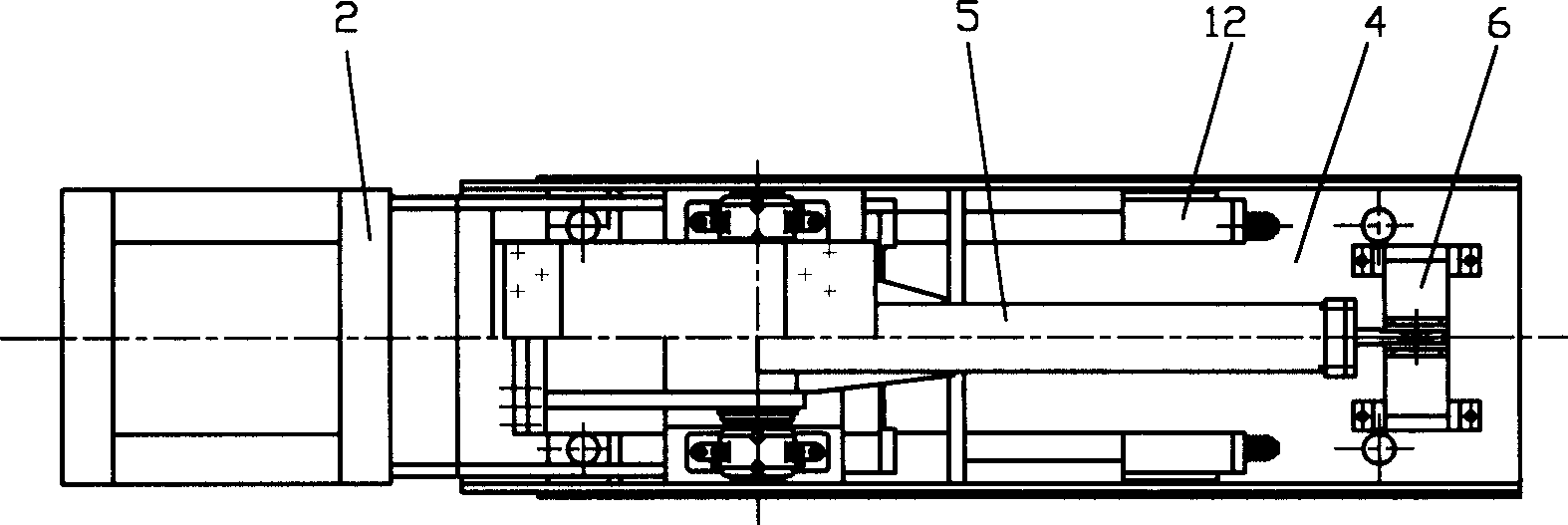

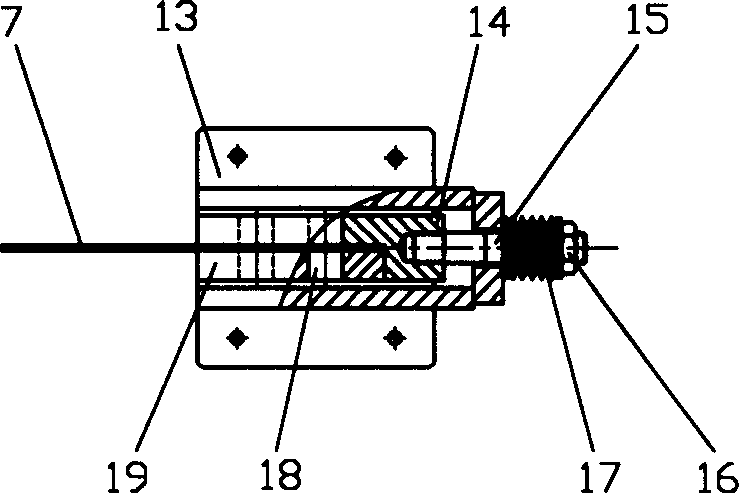

[0019] Example: attached figure 1 is an embodiment of the present invention (see figure 1 , figure 2 ), in the vibration guiding mechanism, the crystallizer 1 is installed on the vibrating table 2, and the vibrating table 2 extends out the extension arm 10, and the upper plate spring 3, the middle plate spring 8 and the lower plate are used between the extension arm 10 and the stand 4 The springs 7 are connected, and one end of the upper leaf spring 3, middle leaf spring 8 and lower leaf spring 7 close to the continuous casting slab is called the inner end, and the other end is called the outer end. The inner end of the upper plate spring 3 is connected with the extension arm 10, the outer end of the upper plate spring 3 is connected with the stand 4, the inner end of the middle plate spring 8 is connected with the stand 4, and the outer end of the middle plate spring 8 is connected with the extension arm 10 Connection, the inner end of the lower leaf spring 7 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com