An improved base frame of hammering type button stitching machine

It is a technology of fastening machine and base, which is applied in the direction of mechanical equipment, belt fasteners, belts/chains/gears, etc. It can solve the problems of difficult use, troublesome, heavy labor, etc., to improve the quality of fastening, Fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

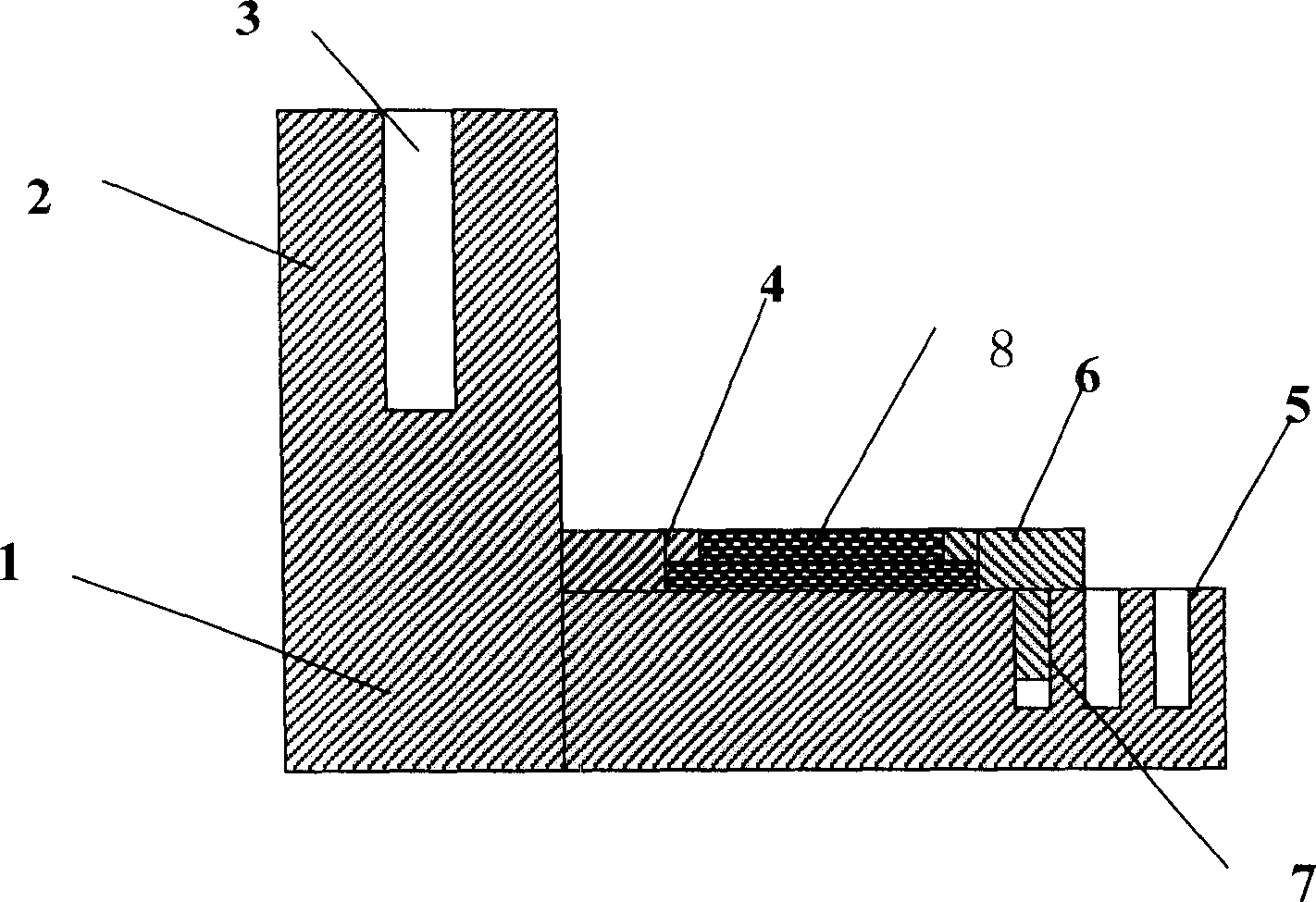

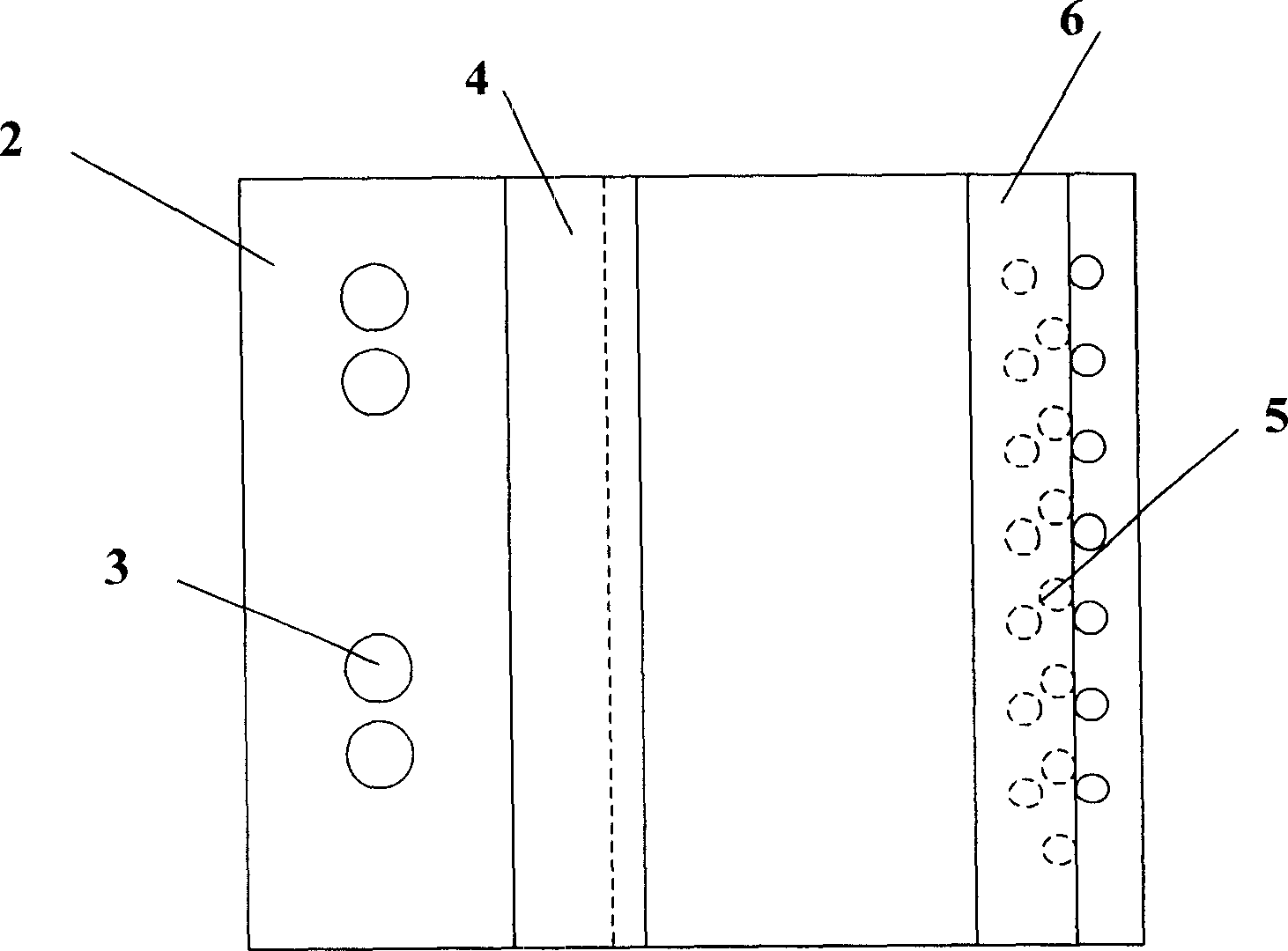

[0012] Such as figure 1 and figure 2 As shown, the present invention is an improved hammer-type button binding machine base, which is composed of a base 1, the rear side of the base 1 protrudes upwards to form a boss 2, and the boss 2 is provided with There is a mold guide pin hole 3, and the front part of the boss 2 is provided with a hinge joint, wherein a step 4 is provided on the upper side of the base 1, and a step 4 is provided on the upper side of the base 1. There are at least two rows of positioning holes 5, the arrangement direction of the positioning holes 5 in any row is parallel to the step 4, and there is an interval between any adjacent two rows of positioning holes 5, and the positioning holes 5 in any row are arranged in parallel with each other. The positioning holes 5 are at least composed of two or more holes arranged, and the positioning holes 5 are all perpendicular to the upper side of the base 1, and a positioning rod is arranged on the upper side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com