Cabin passage arrangement

A channel configuration and cabin technology, applied to ship accessories, living quarters, ships, etc., can solve problems such as difficult work, complicated and slow maintenance and change of cabin channel panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

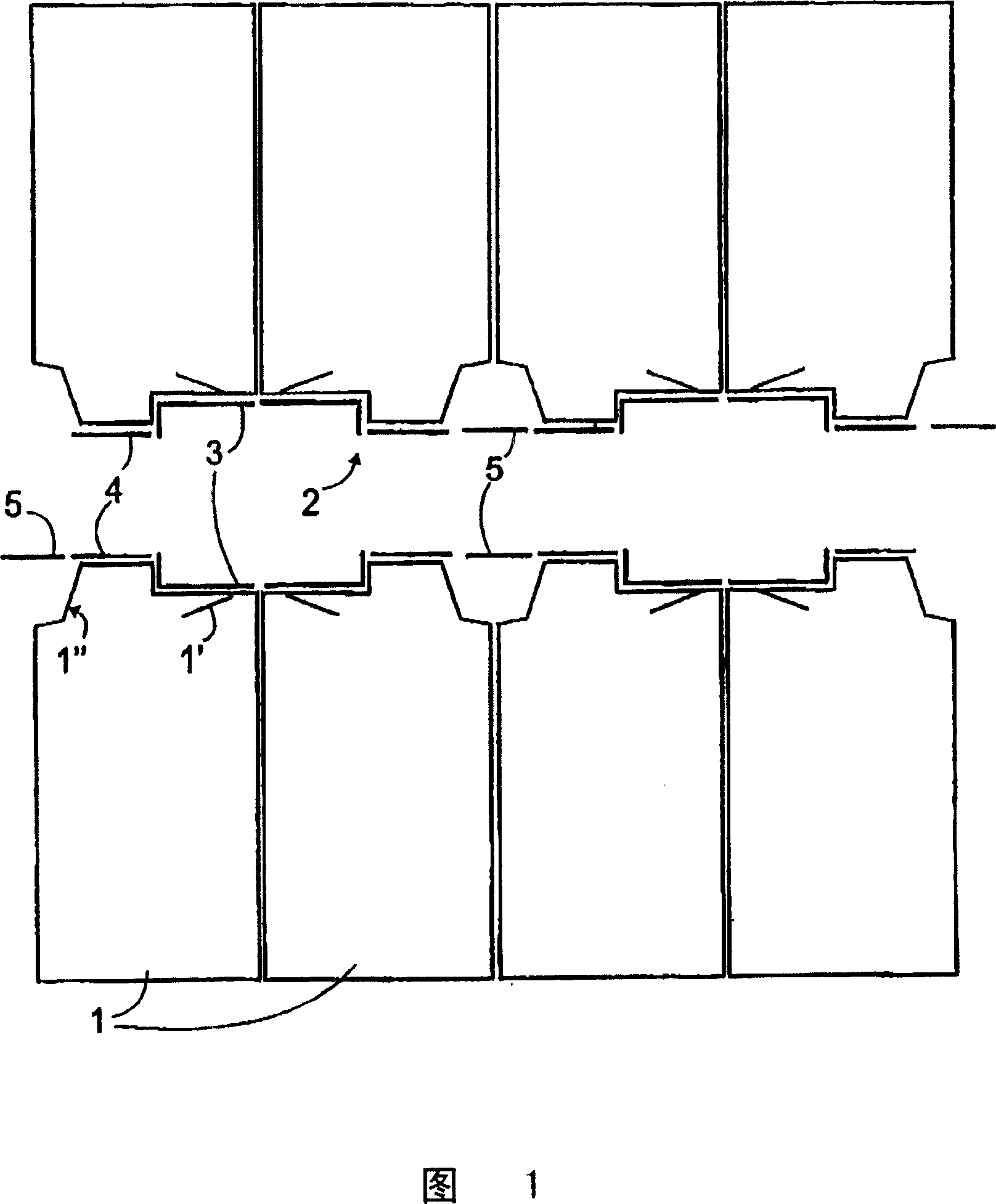

[0028] FIG. 1 shows an example of a cabin module and channel materials included in the cabin module. In a typical cabin 1, the wall facing the maintenance triangle (and triangle area) 1″ and the door 1′ is positioned next to the cabin passage. The wall facing the cabin passage is preferably provided with A wall panel of a cabin passage that forms part of the passage over the distance of the cabin. If some panels (such as ceiling panels and access hatch covers) and the rest of the passage material cannot be pre-installed in the cabin, they will be used as separate elements Shipped with cabin.

[0029] The section 2 of the cabin access wall in the access system comprises for example a door section panel 3, a wall panel 4, an access hatch 5 and a ceiling panel (not shown in Fig. 1 ). The access hatch is the section of the passage wall at the access triangle through which access to the triangle is possible for maintenance and repair work. The access hatch may be a modular sized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com