Pressure safety valve

A safety valve and pressure technology, applied in the field of pressure safety valves, can solve problems such as invalid pillars and easy damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

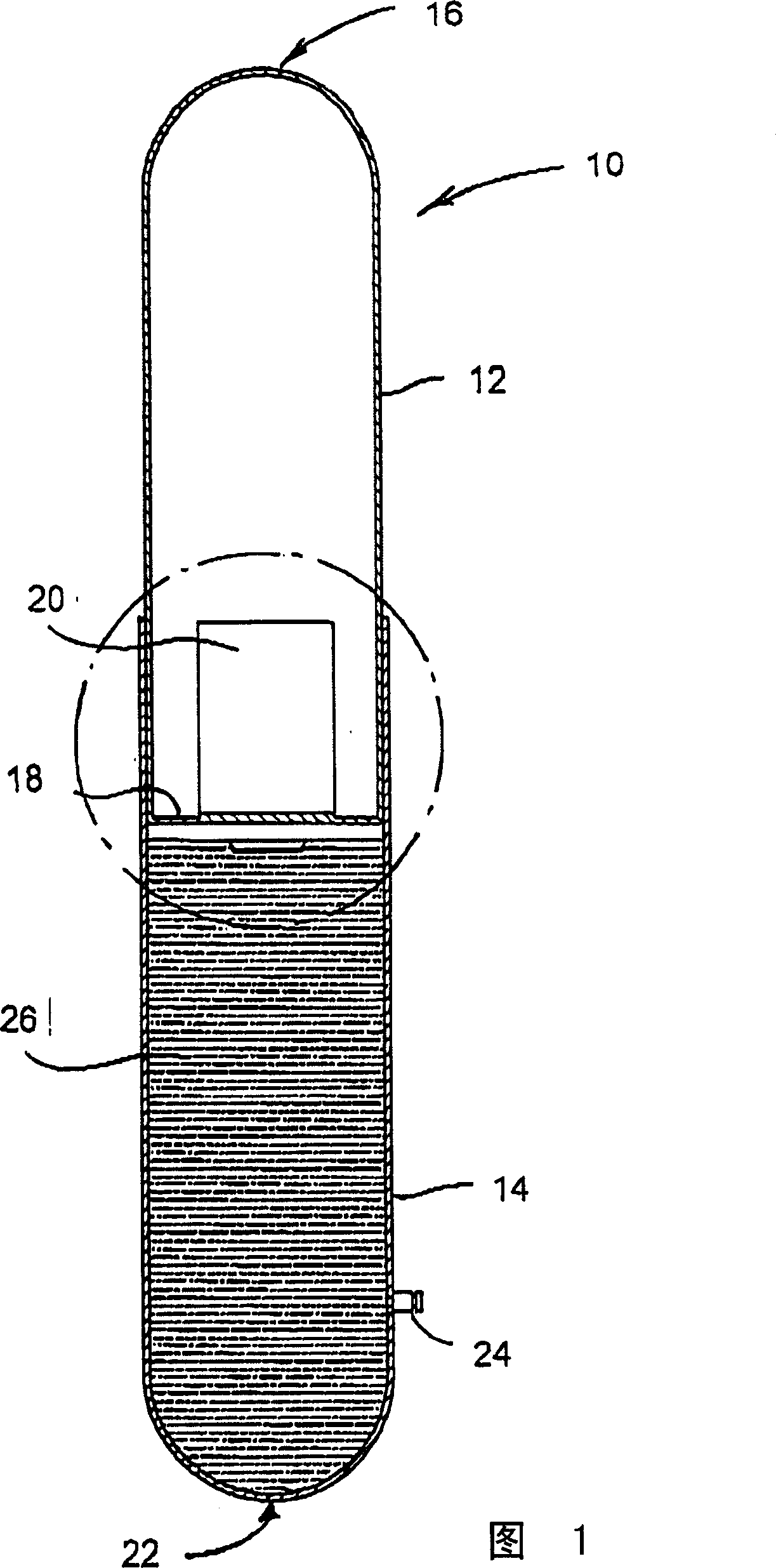

[0013] The figures show a support 10 of the type used, for example, in underground excavations to provide support between a roof wall and an opposing ground wall, the support comprising a first tubular member 12 and a second tubular member 14, so that The second tubular member is telescopically connected to the first member.

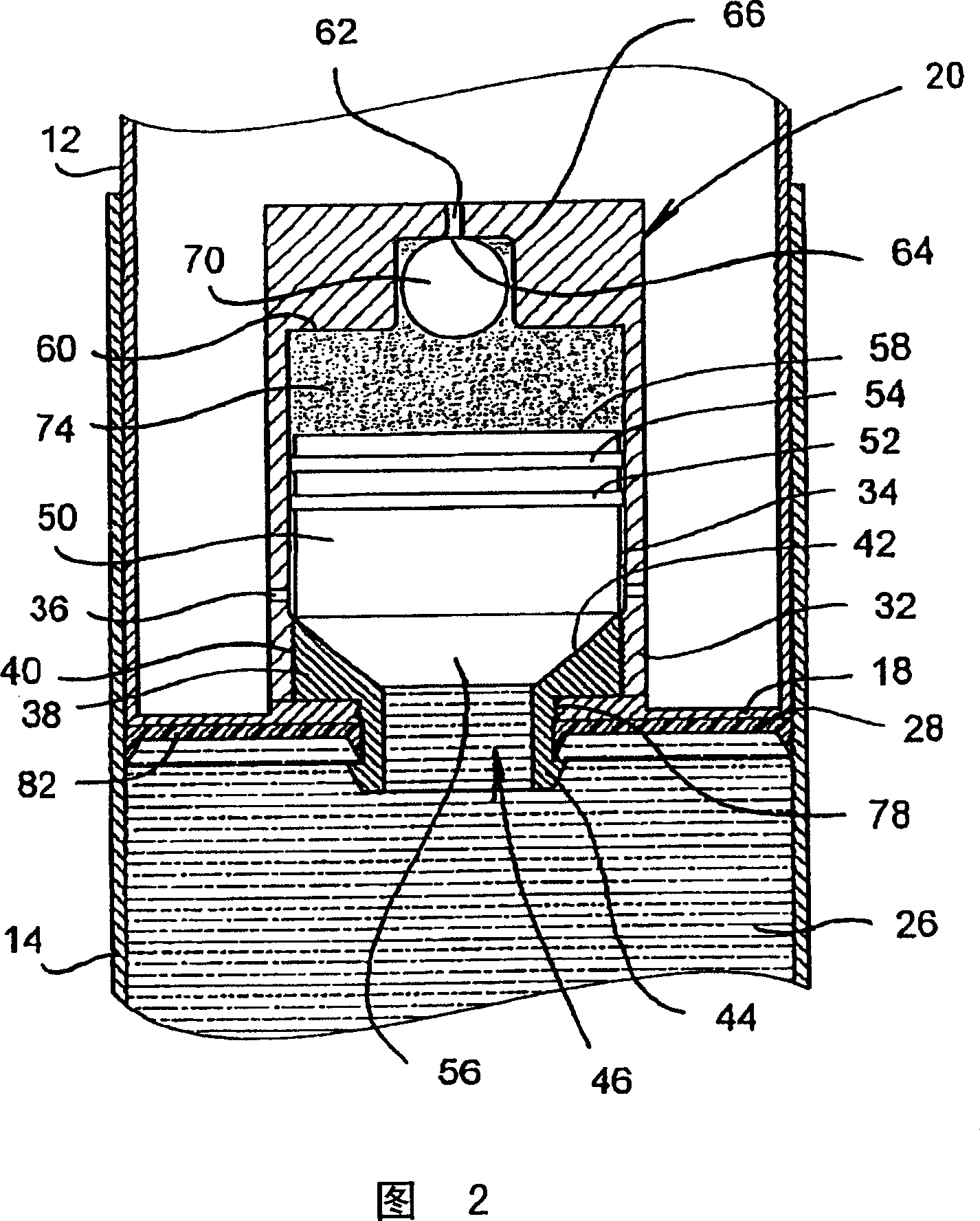

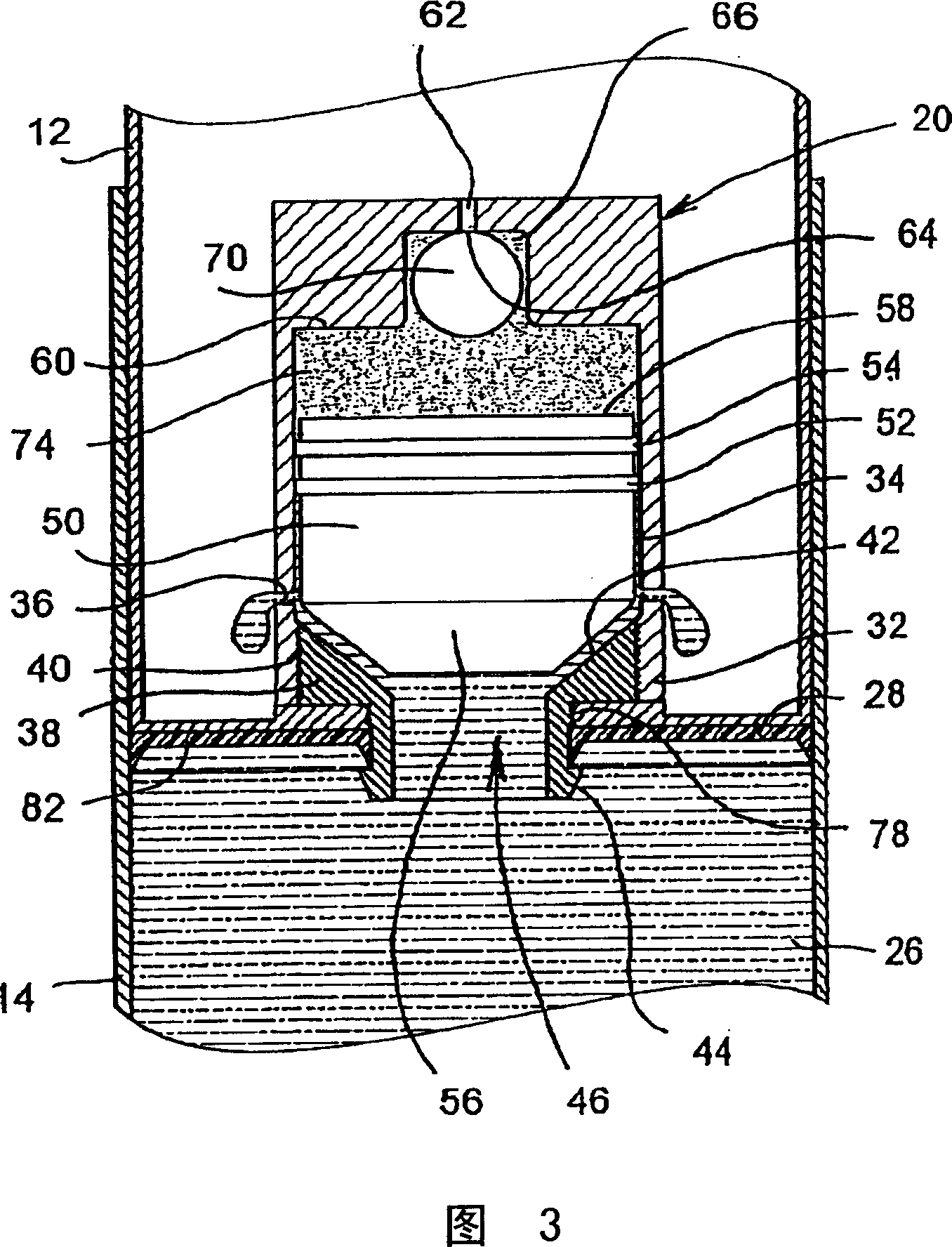

[0014] Member 12 has a circular upper end 16 to which a disc 18 is secured. A valve 20 shown in more detail in Figures 2 and 3 is secured to the disc.

[0015] Tubular member 14 has a circular lower end 22 and a one-way injection valve 24 affixed to the side wall. A volume 26 is defined within the second member 14 . A seal 28 engaging the disc 18 faces the volume 26 and provides a sealed interface between the components 12 and 14 .

[0016] Valve 20 includes a housing 32 defining a chamber 34 therein. A plurality of outlets 36 are formed through the wall of the housing. The valve seat 38 has threads 40 which threadably engage complementary threads i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com