Manufacture method for motor and motor

A manufacturing method and motor technology, which can be used in electrical components, electromechanical devices, etc., and can solve problems such as difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

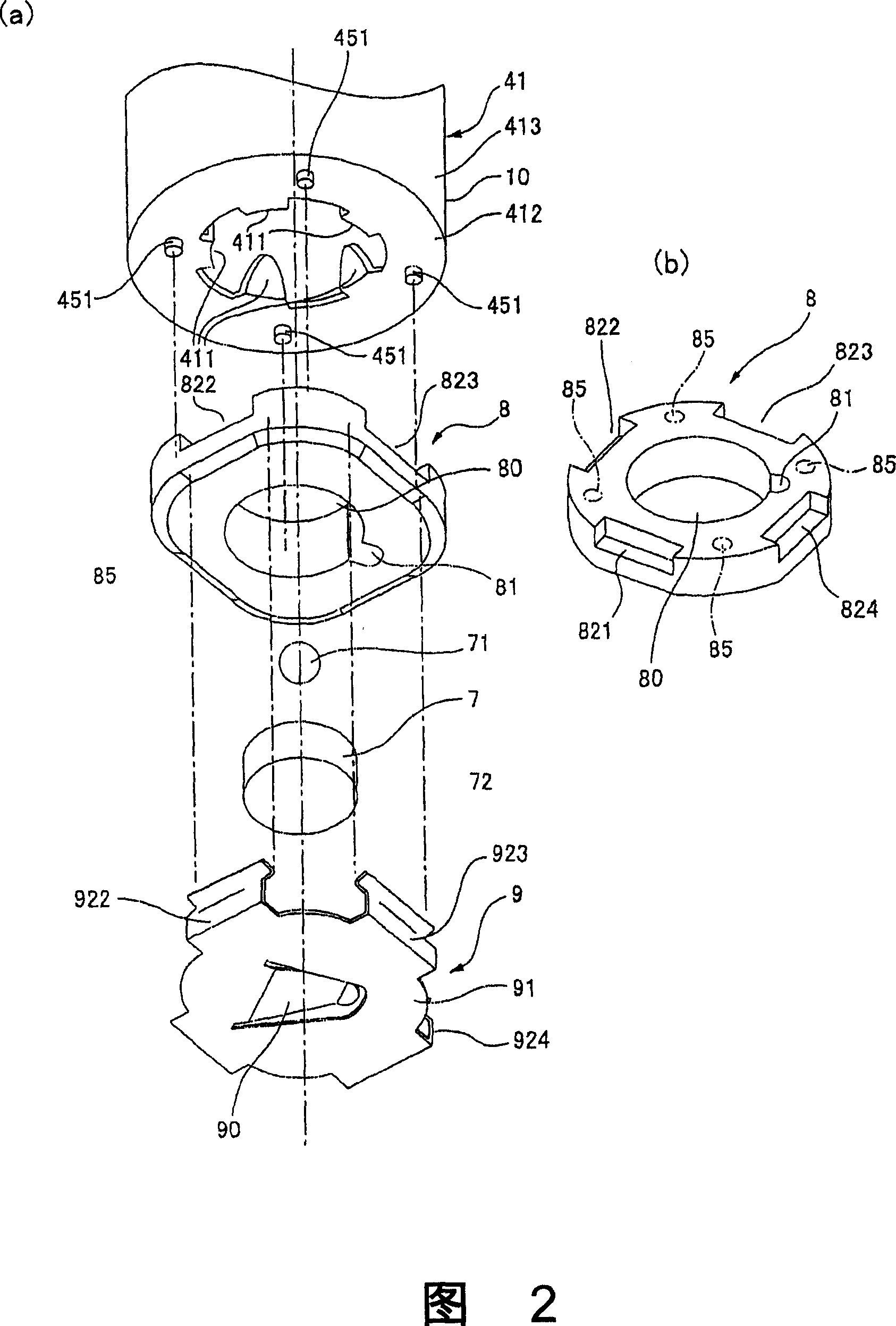

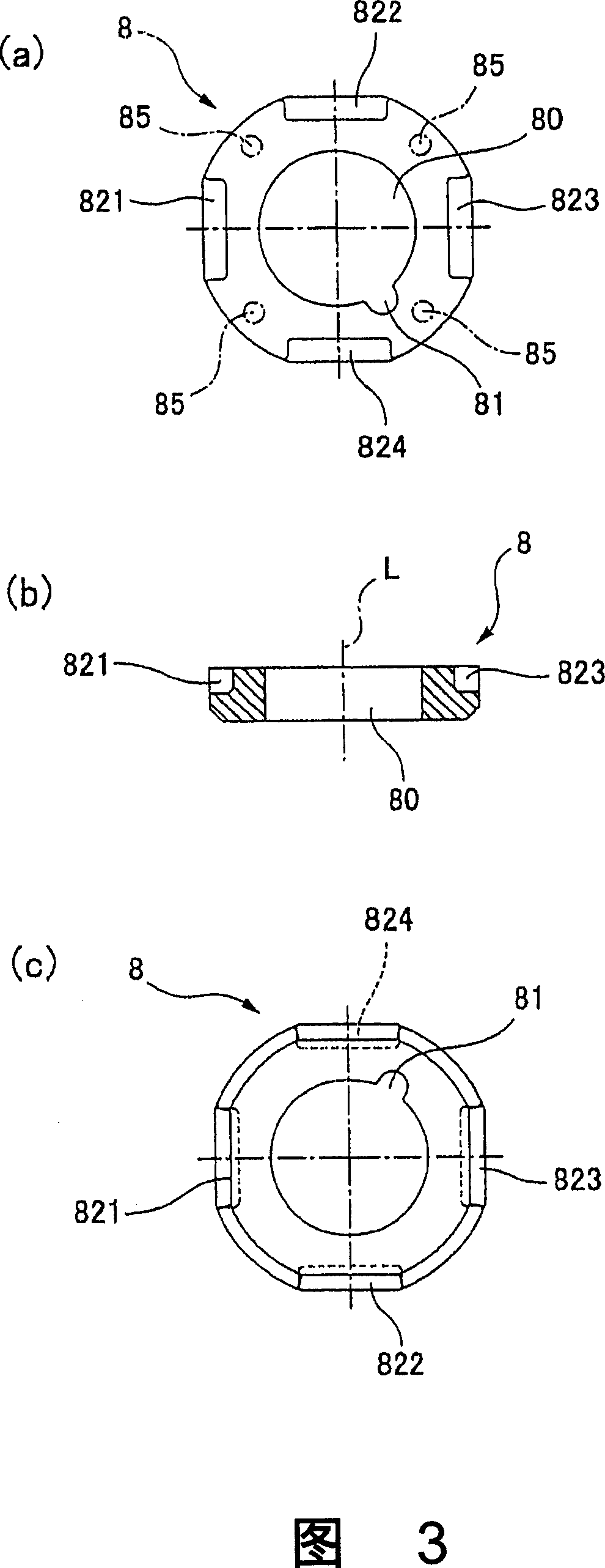

[0027] Embodiments of the present invention will be described below with reference to the drawings.

[0028] (whole structure)

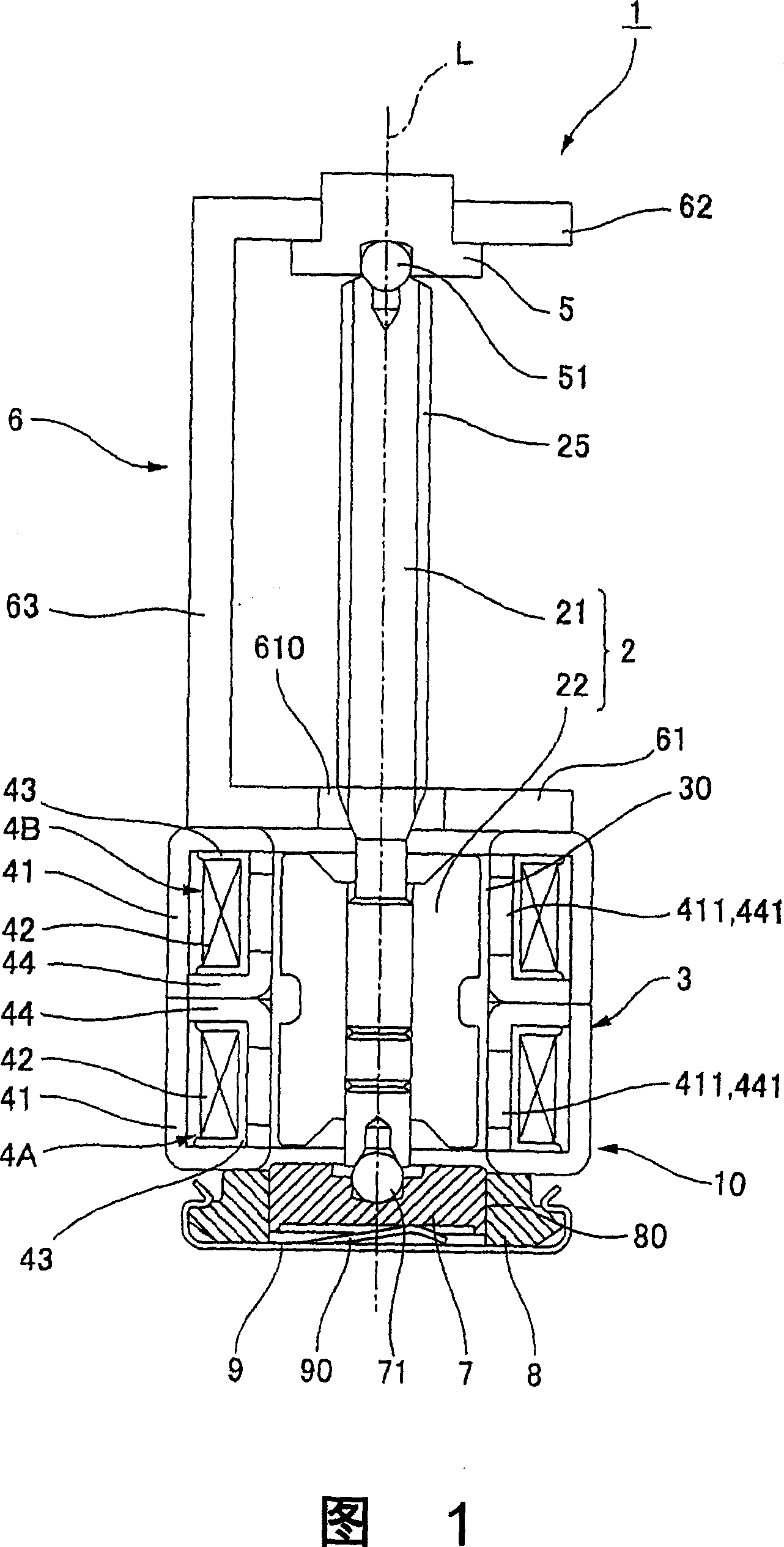

[0029] Fig. 1 is a sectional view of a stepping motor to which the present invention is applied.

[0030] As shown in the figure, the motor 1 of this form is a small PM-type stepping motor used in digital cameras, digital video cameras, FDDs, ODDs, etc., and has a rotor 2 including a rotating shaft 21, including a coaxial arrangement of the rotor. The stator 3 of the hole 30 is arranged in the rotor on the base end side of the rotor 2 .

[0031] The stator 3 includes an anti-output-side stator group 4A and an output-side stator group 4B, and these stator groups 4A, 4B are arranged in a two-phase configuration overlapping each other in the motor axis L direction. The stator groups 4A and 4B both have: an outer stator core 41; an annular bobbin 43 wound with a coil 42; The end faces of the sub-cores 44 are fixed. A plurality of pole teeth 411 , 441...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com