Boot with adjustable fitting

a technology of adjustable fitting and boot, which is applied in the field of boots, can solve the problems of not being able to adjust the zipper b>1/b> to tighten or loosen the boot, the boot would become loose, and the foot cannot be properly positioned on the foot of different users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

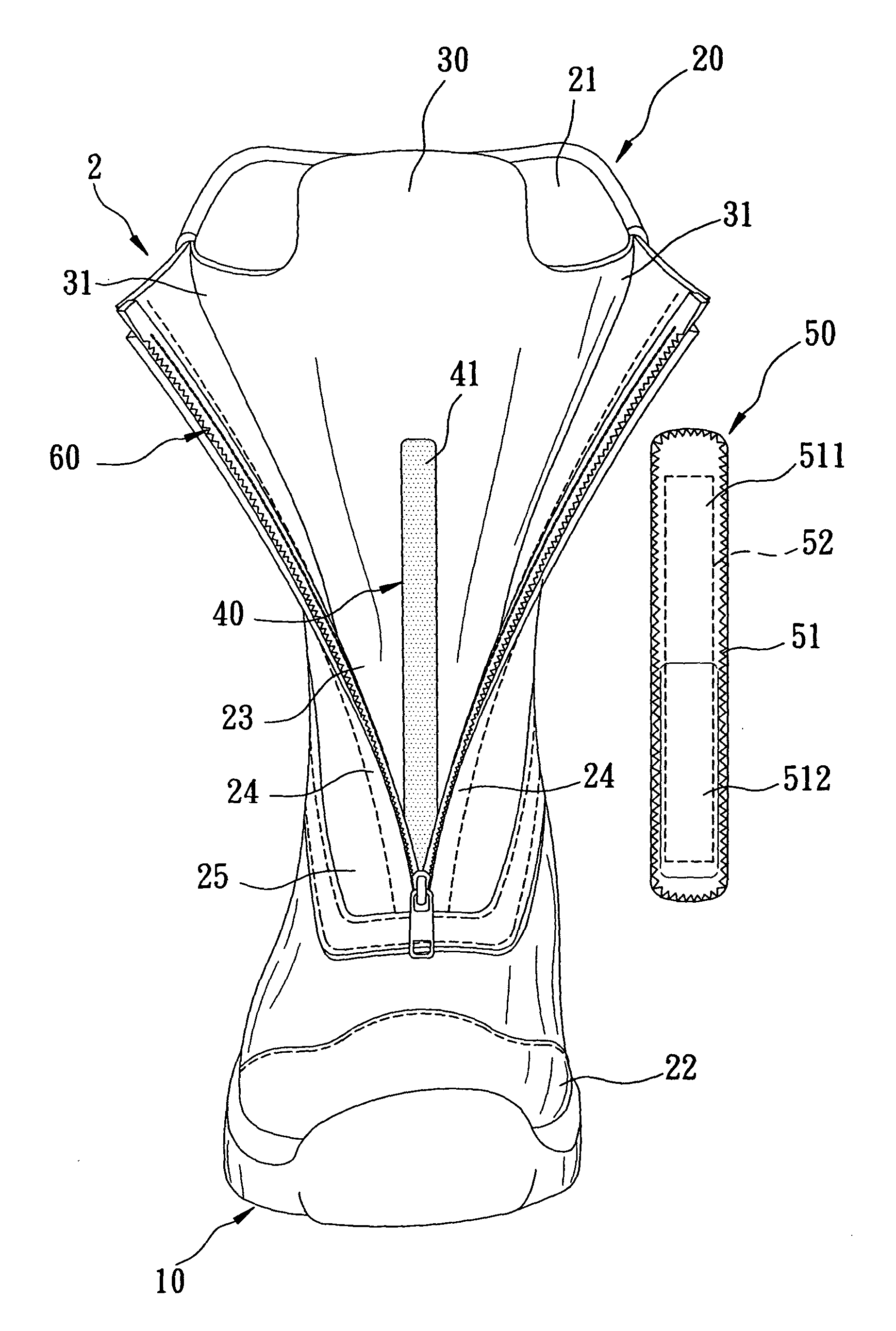

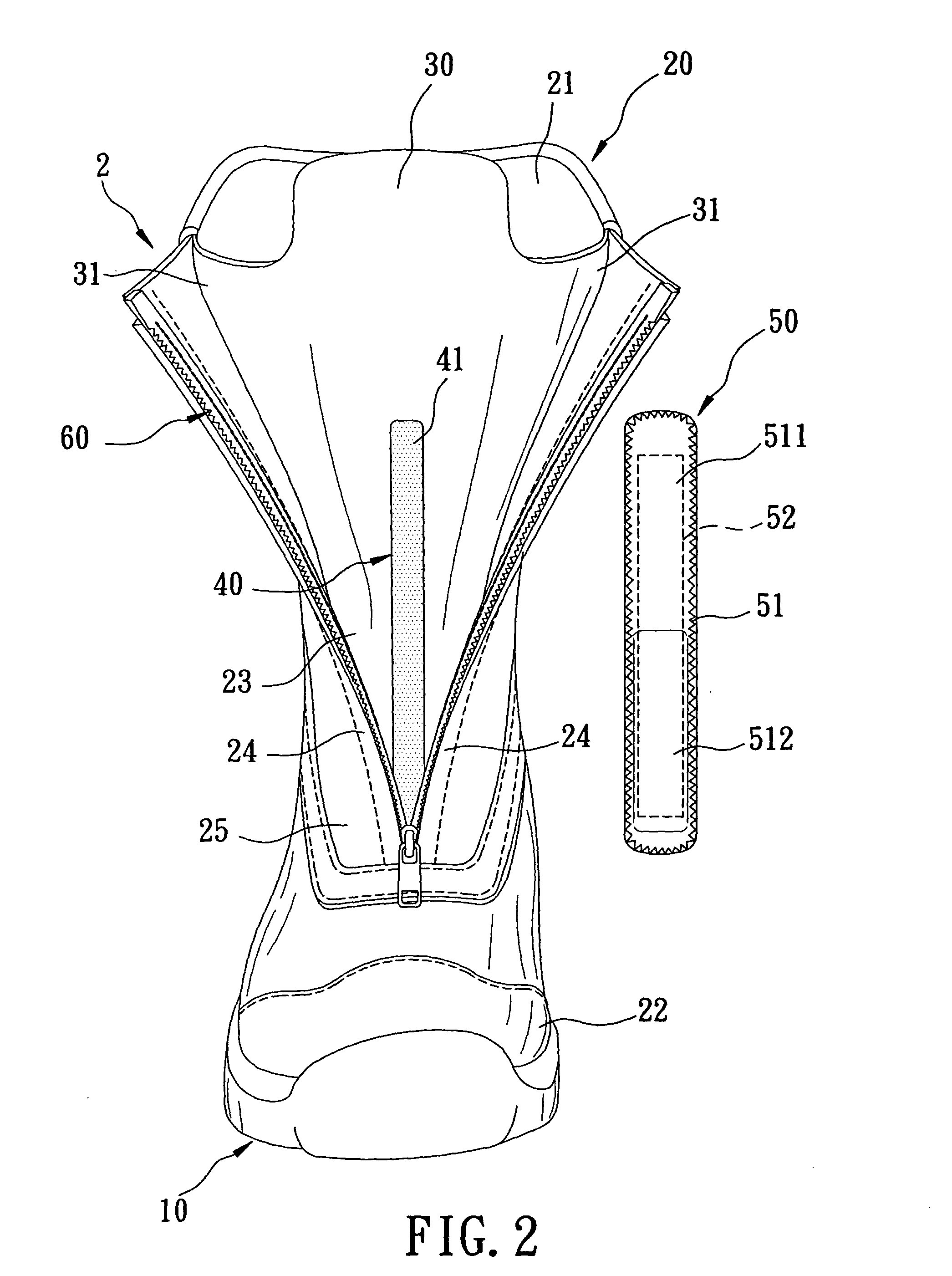

[0023] Referring to FIGS. 2 and 3, the present invention includes a boot 2 which has an outsole 10 connected to a shell 20. The shell 20 includes an upper portion 21 connected to a foot portion 22, an instep part 25 at the juncture of the upper portion 21 and the foot portion 22, and an opening 23 which extends from the instep part 25 to an open top end of the upper portion 21. The opening 23 is defined by an opposed pair of margins 24 of the shell 20. A closure member, such as a zipper 60, is attached to the margins 24 to close the opening 23.

[0024] A liner 30 has two opposite ends 31 which are attached to the inner surface of the shell 20 on two sides of the opening 23 so that the liner 30 underlies the opening 23 and the margins 24, and has an outer surface facing the opening 23 and the margins 24. The outer surface of the liner 30 and the inner side of the margins 24 cooperatively define a space 26 (see FIG. 4). The liner 30 is made of a flexible material, preferably a stretchab...

third embodiment

[0030] Referring to FIGS. 7, 8 and 9, the present invention differs from the first embodiment as follows: This embodiment includes a retaining unit which is formed as a stud 43 to retain an adjustment pad 50′, and an closure member which is configured to include two complementary velcro straps 61 and 62. The adjustment pad 50′ in this embodiment is similar to that of the second embodiment and is pivotable about the stud 43 so as to turn the thin or thick section 511 or 512 thereof downward to a position close to the instep part 25. The positions of the thin and thick sections 511 and 512 are therefore interchangeable by turning the adjustment pad 50′ about the stud 43. When the wearer puts on the boot and interengages the velcro straps 61 and 62, the opening 23 is closed so that the space between the liner 30 and the margins 24 is stuffed. This increases the tightness of the boot at the instep part 25.

[0031] Referring to FIGS. 10 and 11, a fourth embodiment of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com