Luggage assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

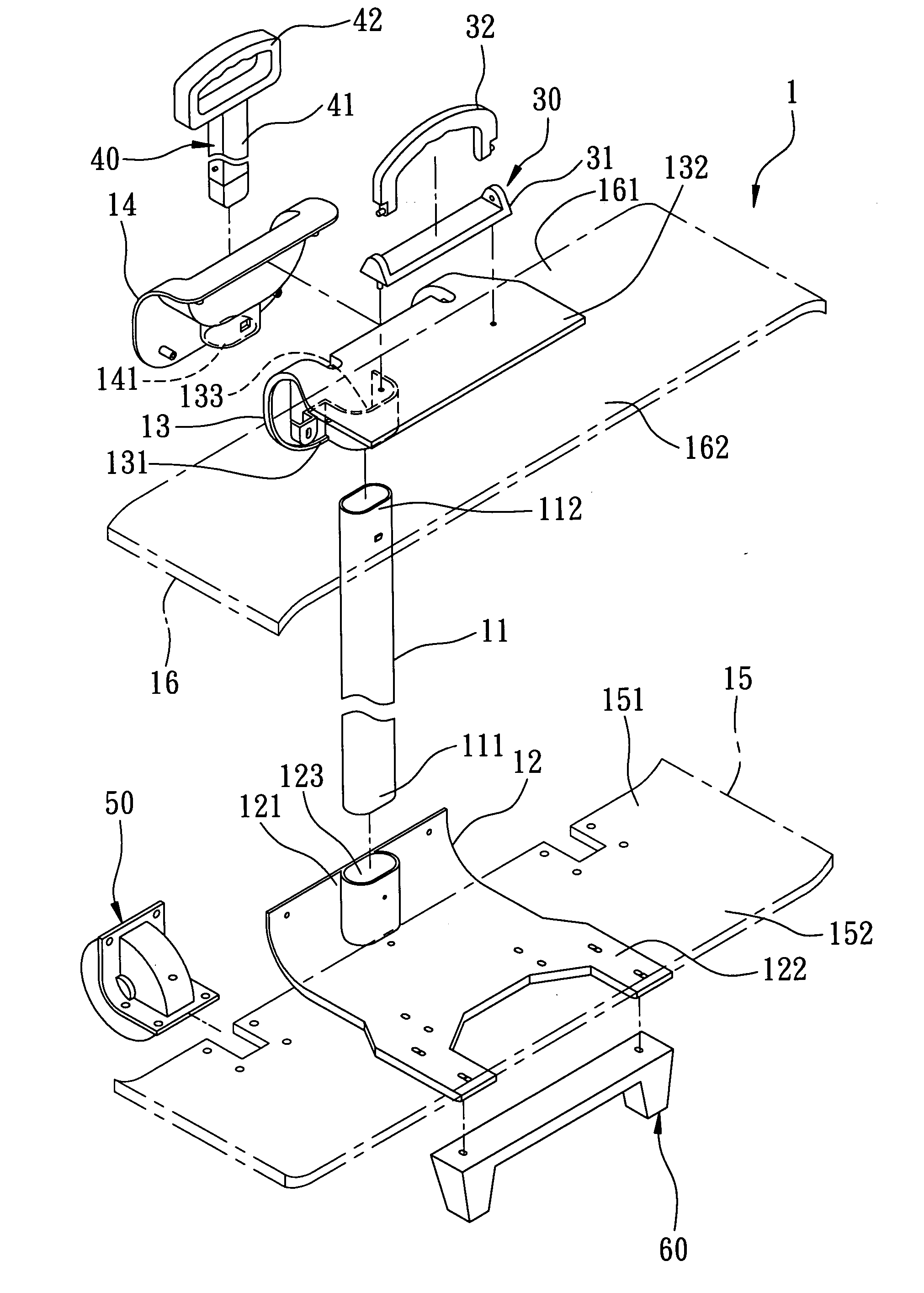

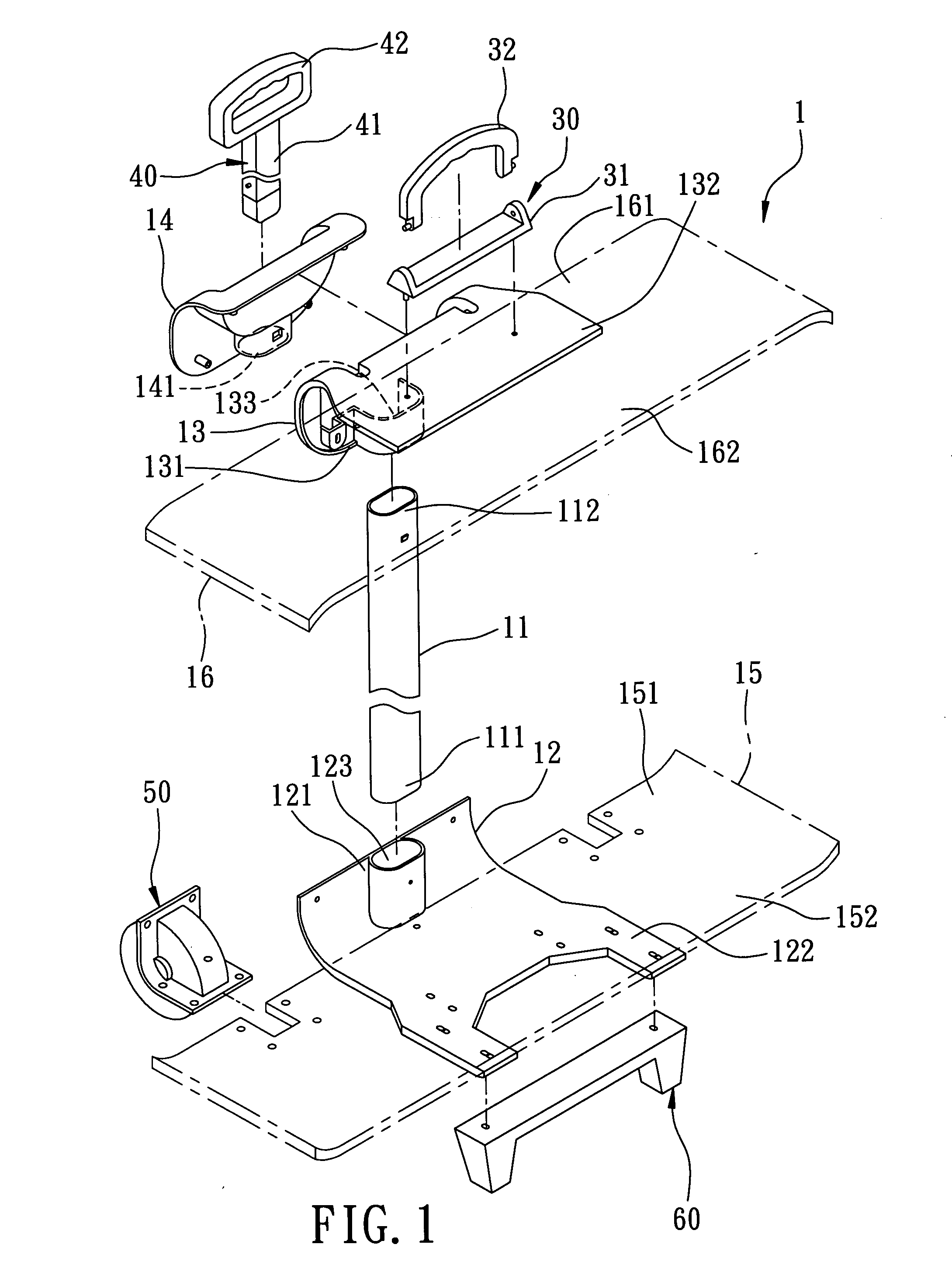

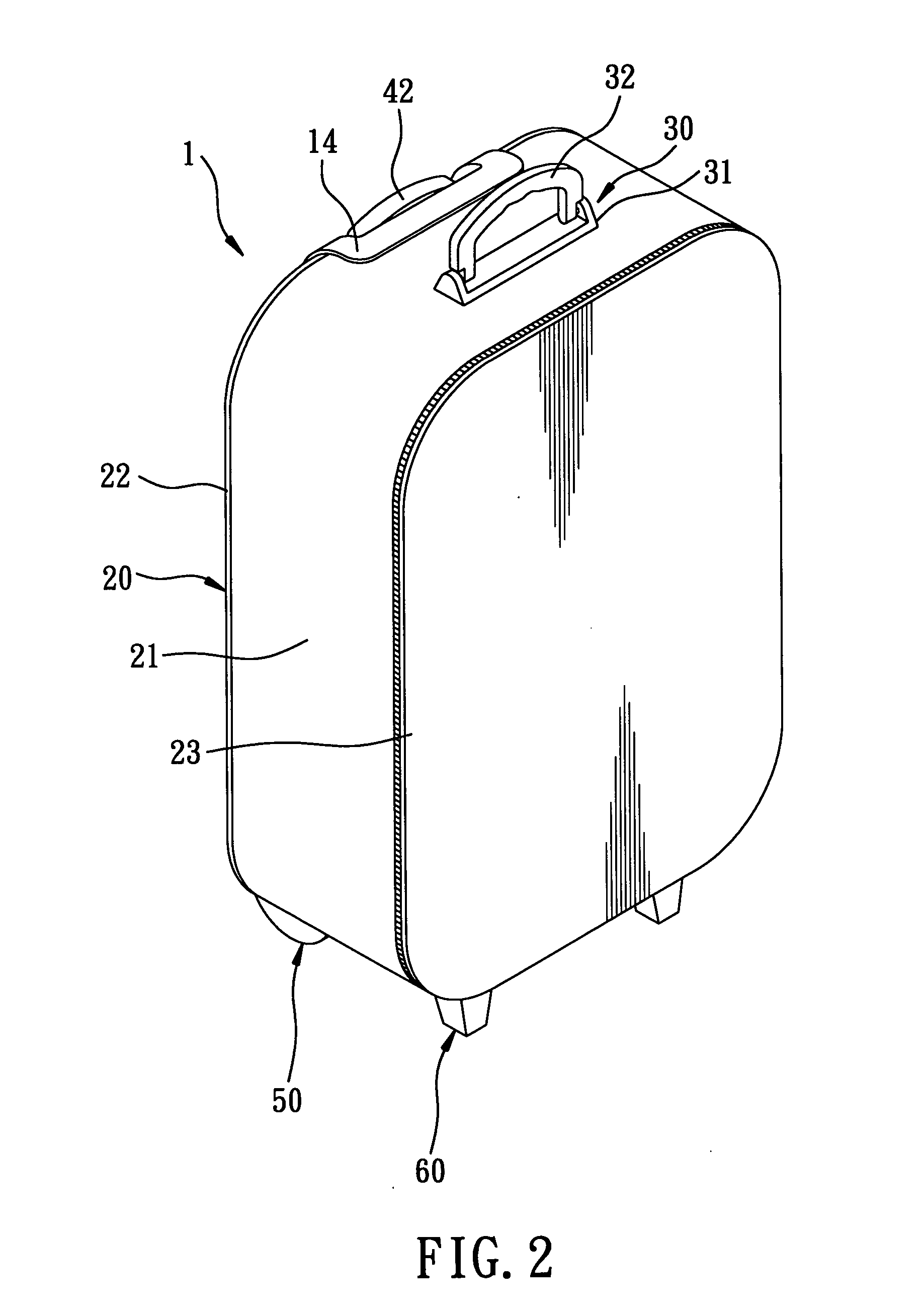

[0013] Referring to FIGS. 1 to 3, the preferred embodiment of a luggage assembly 1 according to this invention is shown to include an upright tubular member 11, upper and lower mounting seat members 13, 12, upper and lower horizontal plate members 16, 15, a luggage shell 20, and a pull handle unit 30.

[0014] The tubular member 11 has top and bottom end portions 112, 111. Each of the upper and lower mounting seat members 13, 12 is made of a rigid plastic material, has front and rear end portions 132, 122, 131, 121, and is generally L-shaped. In particular, each of the upper and lower mounting seat members 13, 12 has a horizontal section that serves as the front end portion 132, 122 and a vertical section that serves as the rear end portion 131, 121. Each of the front end portions 132, 122 of each of the upper and lower mounting seat members 13, 12 has top and bottom sides. Each of the rear end portions 131, 121 of the upper and lower mounting seat members 13, 12 is formed with an ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com