Breakaway antenna

a technology for antennas and antennas, applied in the direction of antennas, antenna details, antenna adaptation in movable bodies, etc., can solve the problems of large, heavy duty antennas mounted on military vehicles, antennas to break, and cannot withstand the size and conditions of military antennas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

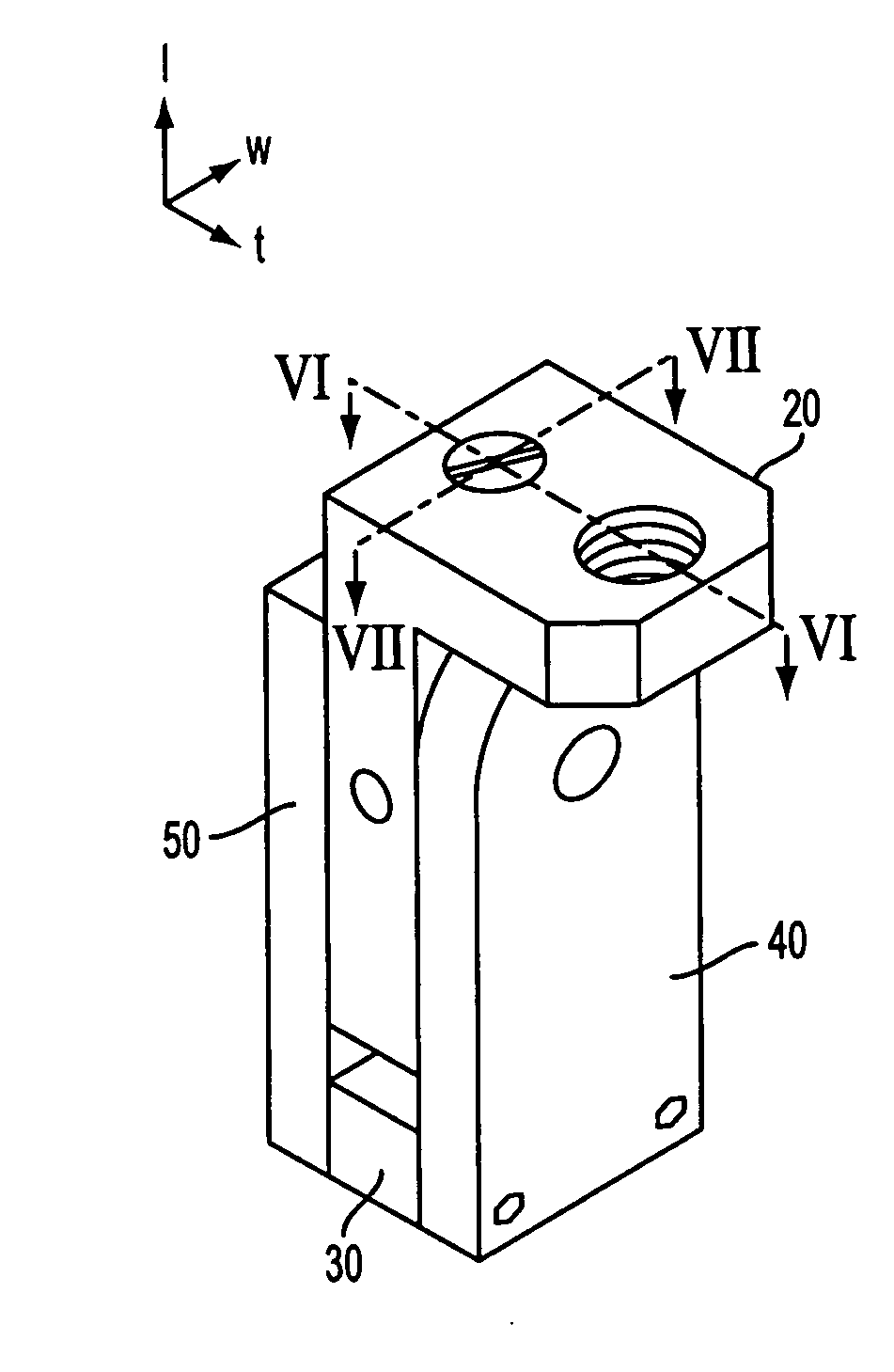

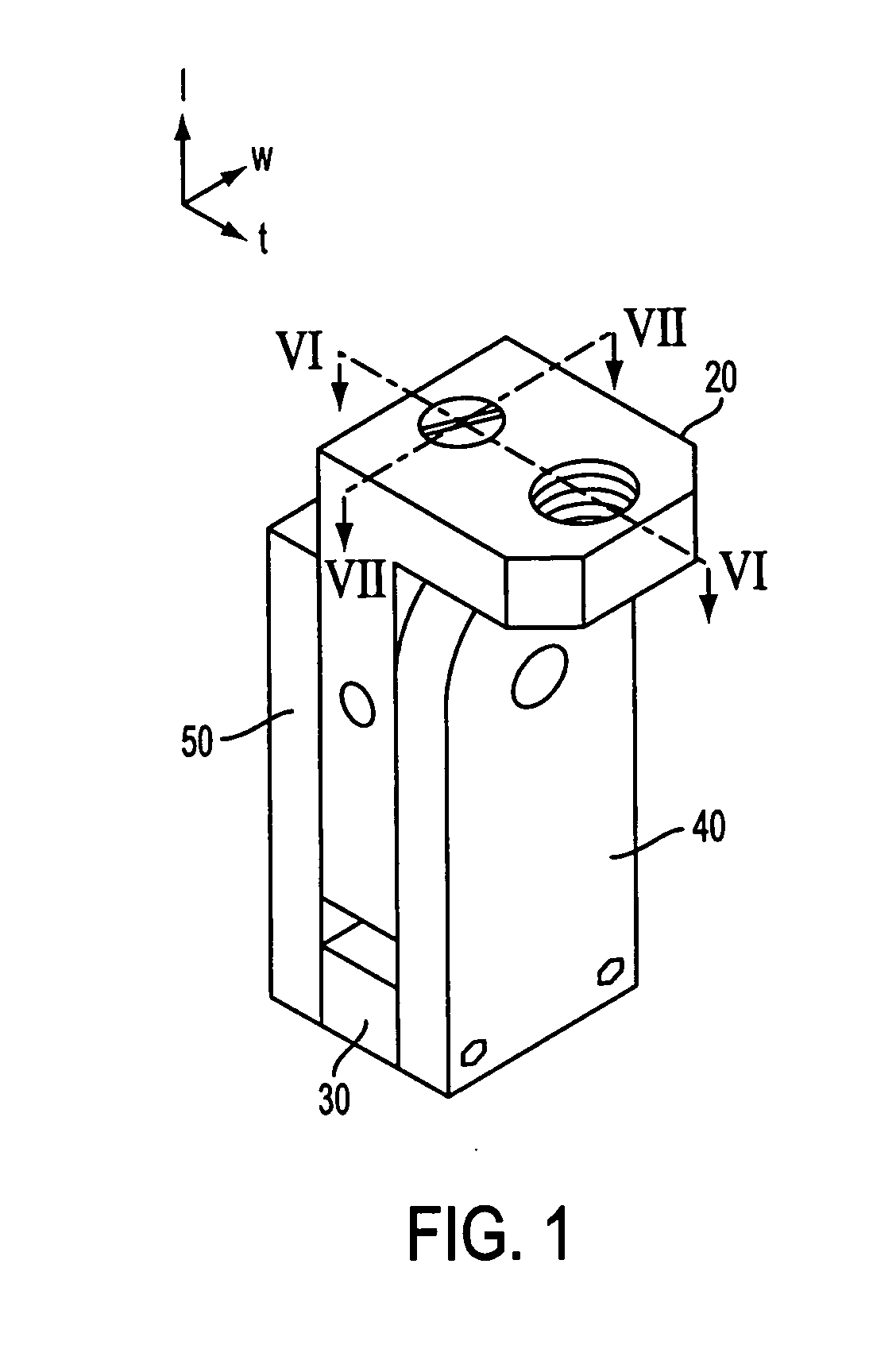

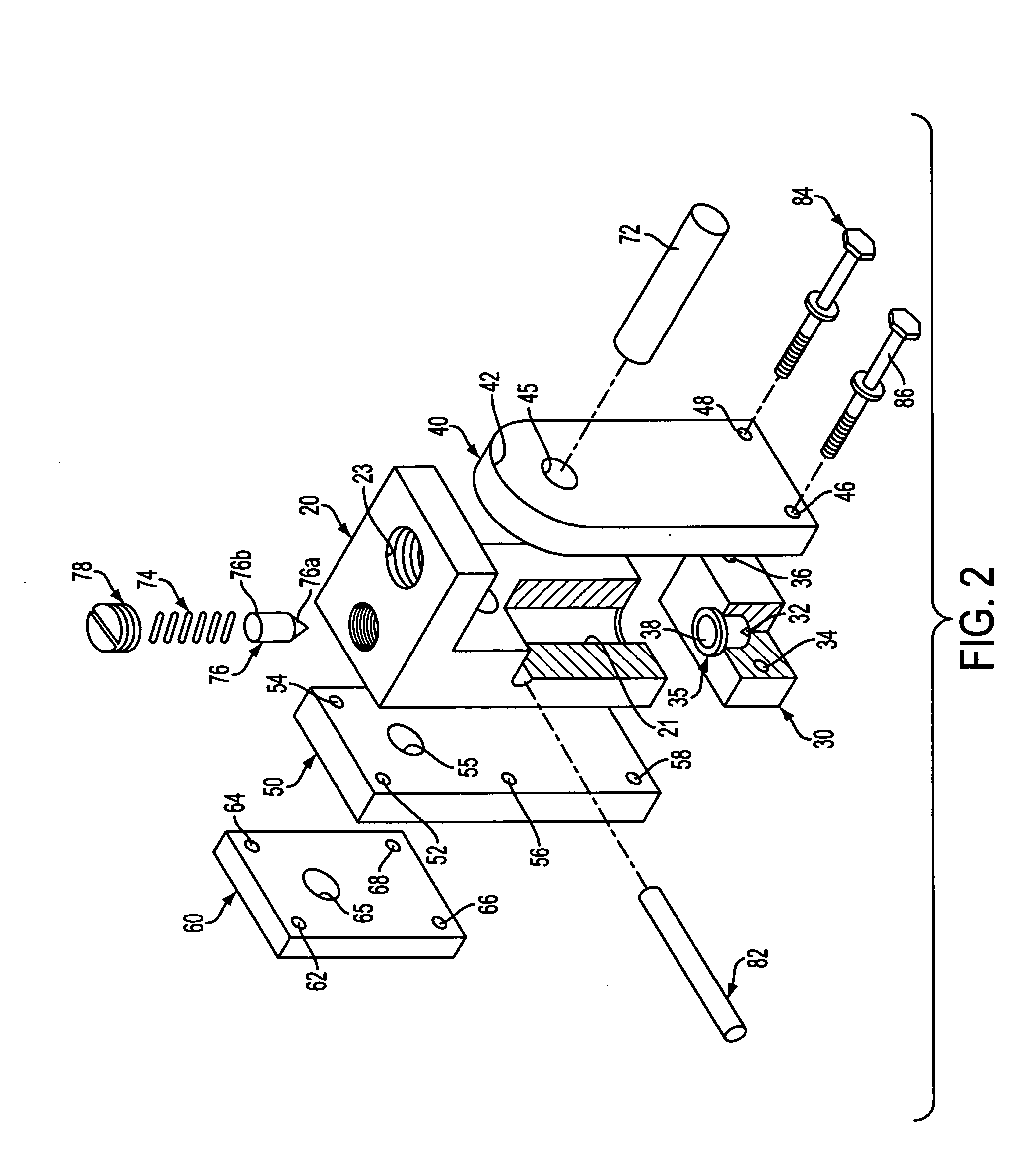

[0018]FIG. 1 shows an antenna mount 10 according to an embodiment of the present invention, while FIG. 2 shows an exploded view of the antenna mount 10. Generally, the antenna mount 10 includes a front plate 40, a back plate 50, a separator 30 and a rotator 20.

[0019] As best seen in FIG. 2, front plate 40 has a pivot bore 45 formed through the thickness of the plate at an upper region thereof, and two parallel bores 46, 48 formed through the plate and near the bottom corners of the plate. Preferably, though not necessarily, the upper end of the front plate 40 has a rounded contour 42.

[0020] The structure of the back plate 50 is similar to that of the front plate 40 in that the back plate 50 also has a pivot bore 55 extending through the thickness of the plate and a pair of parallel bores 58 (only one shown in FIG. 2) formed through the plate near the bottom corners thereof. Additionally, back plate 50 also includes two additional pairs of bores 52, 54 and 56 (only one shown in FIG...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com