Bugproof and odorproof sealing ring structure of a sinkhole screen

a technology of sealing ring and sinkhole, which is applied in the direction of washstands, water installations, constructions, etc., can solve the problems of gum ring elastically failing, gum ring elastic deformation, gum ring loss,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

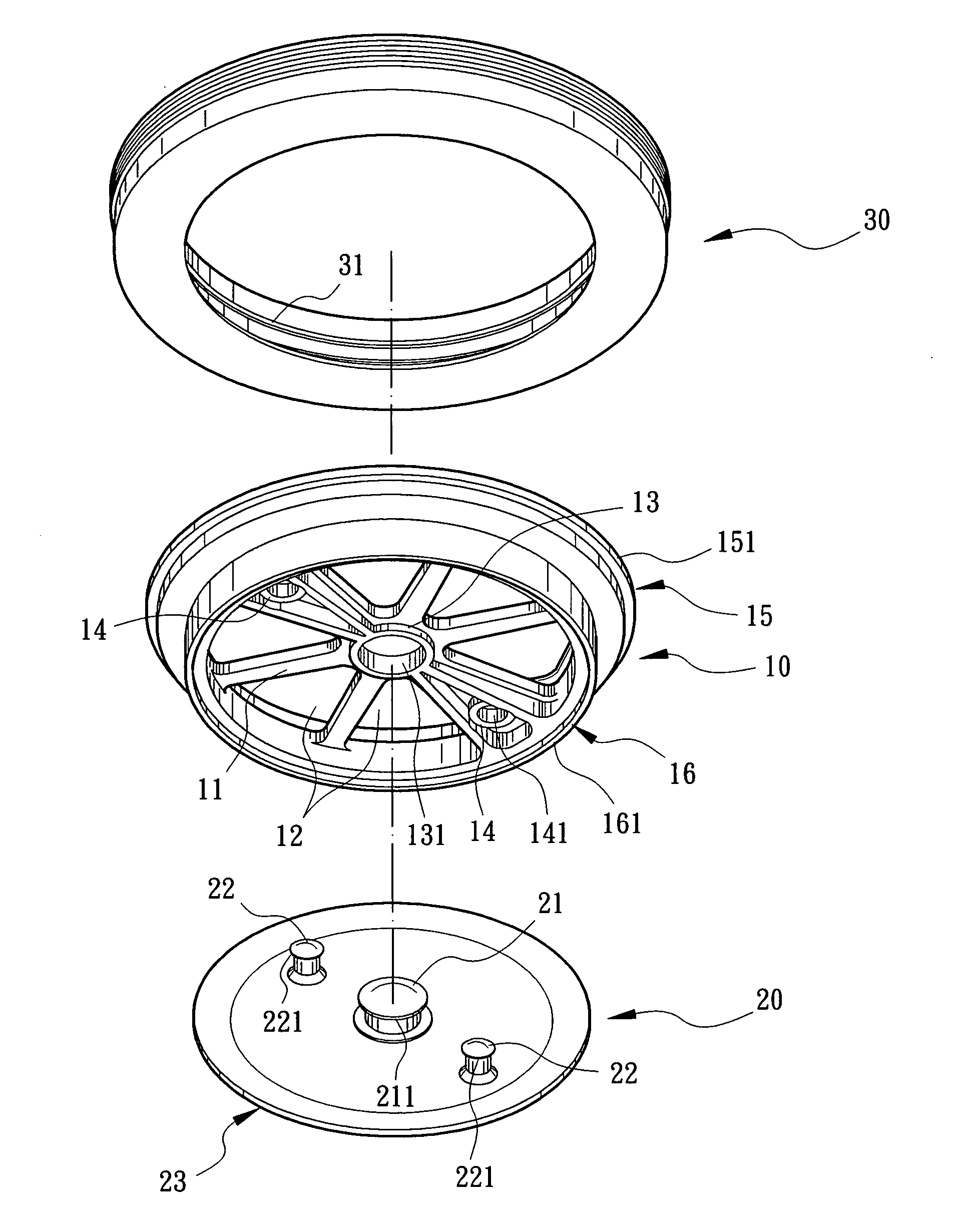

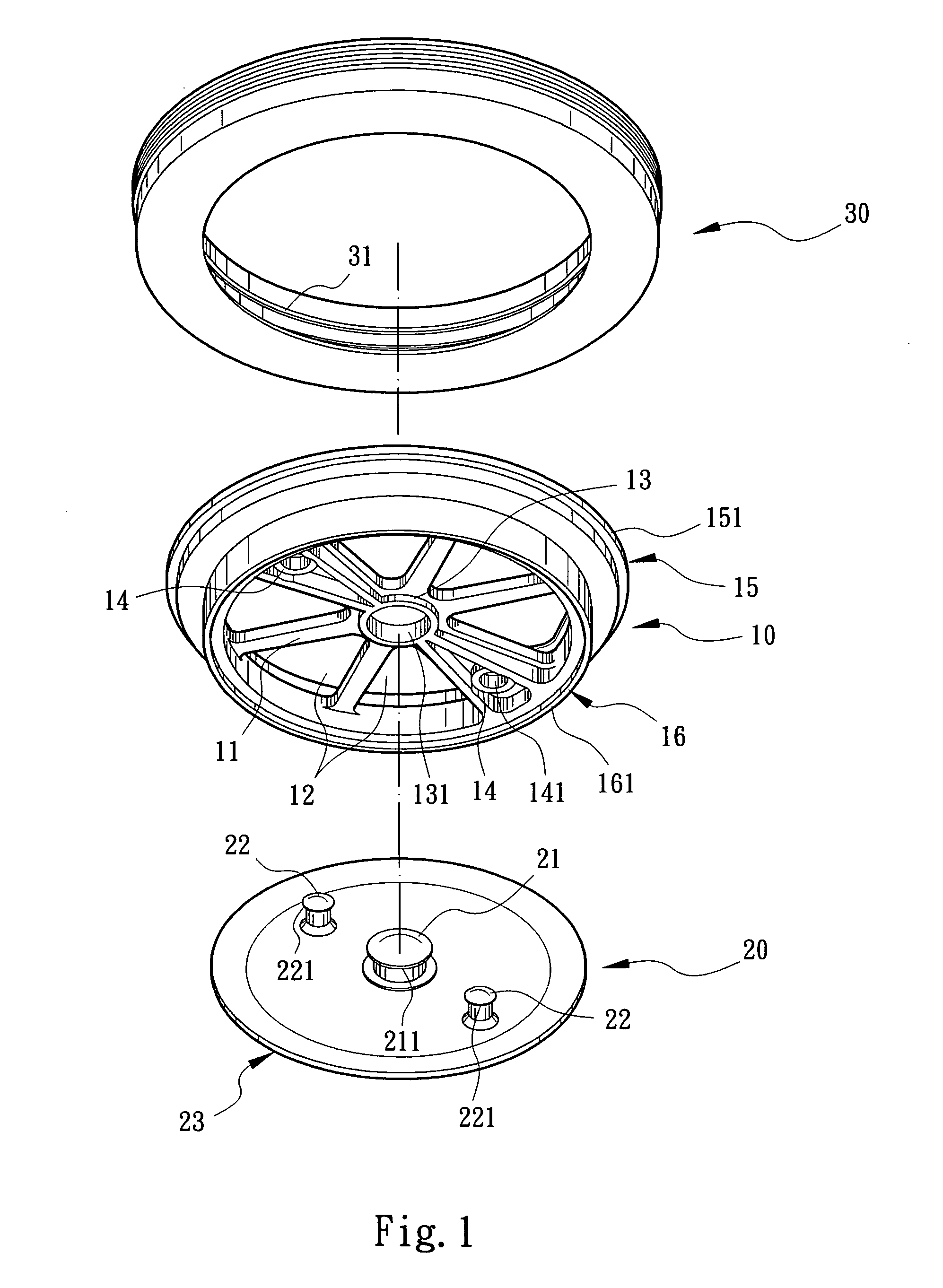

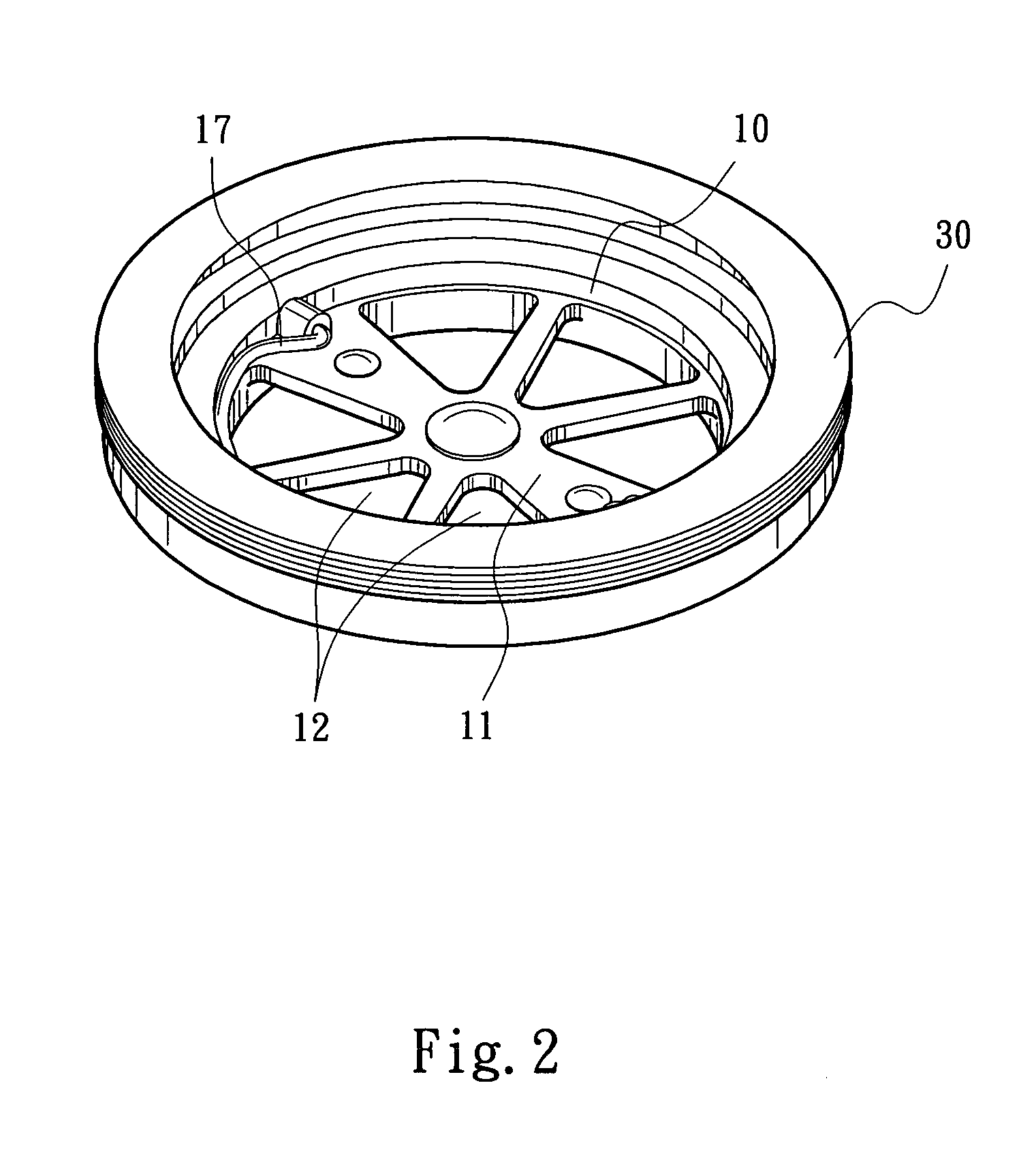

[0017] Please refer to FIG. 1. The sealing ring structure of the sinkhole screen of the present invention includes a base seat 10, a diaphragm 20 and a gum ring 30. Referring to FIGS. 2 to 5, the base seat 10 is a substantially ring-shaped body integrally made of metal or plastic material. The central portion of the base seat 10 is formed with a screen section 11 having multiple perforations 12. The center and the circumference of the screen section 11 are respectively formed with holders 13, 14. The upper end of the base seat 1 is formed with a flange 15. The lower end of the base seat 1 is formed with a skirt 16. The flange 15 can be a stepped flange having a step 151. The skirt 16 can be a stepped skirt having a step 161. A lift ring 17 is disposed on the base seat 10 for lifting the sealing ring.

[0018] The diaphragm 20 is substantially a thin disc integrally made of elastic and weatherproof rubber or semisoft plastic material. The diaphragm 20 has chucking bosses 21, 22 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com