Ultra-thin liquid-filled insole interface

a liquid-filled insole and ultra-thin technology, applied in the direction of uppers, bootlegs, stiffners, etc., can solve the problems of reducing the friction of the foot, and being relatively thick, and avoiding the effect of friction on the foo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

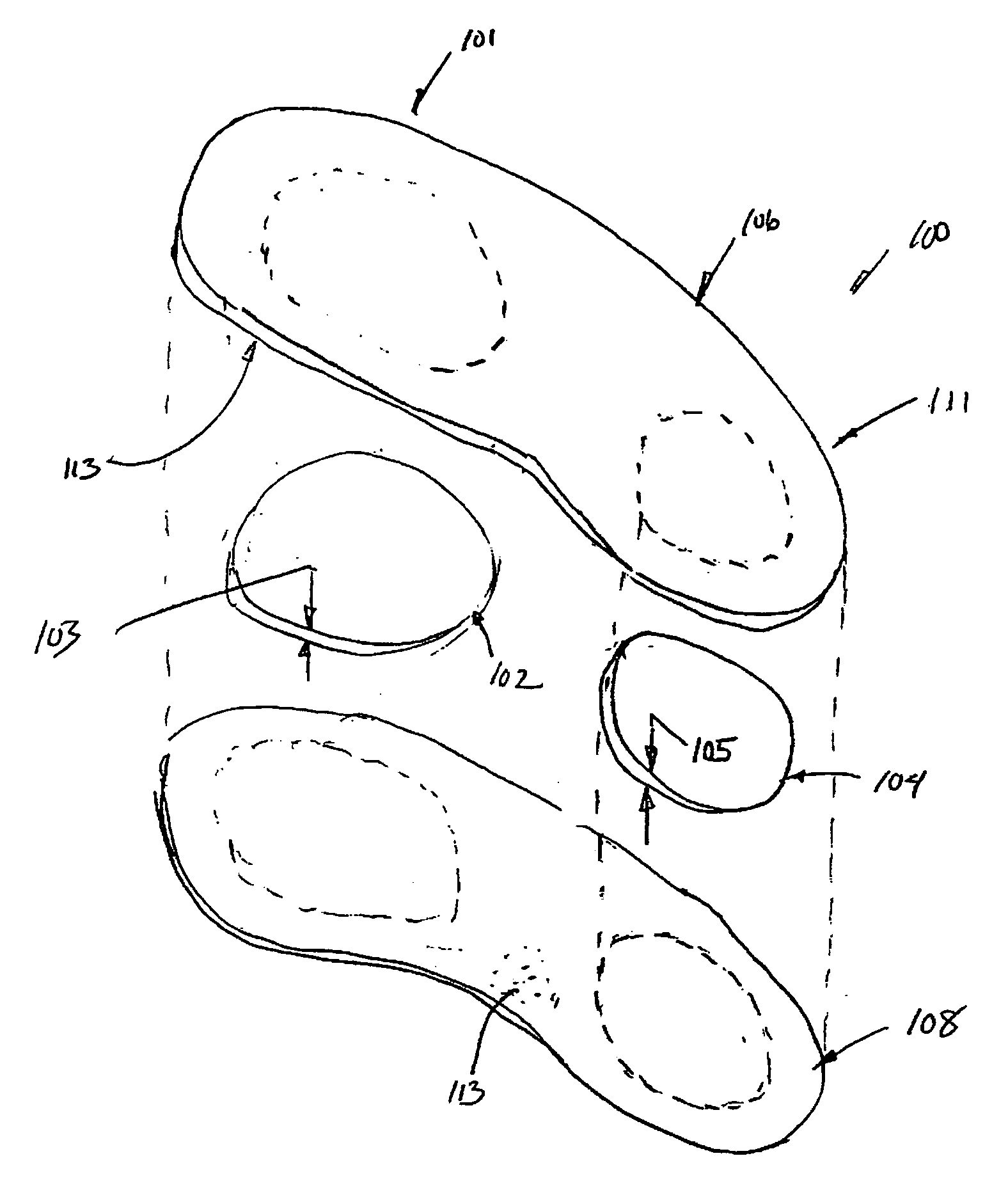

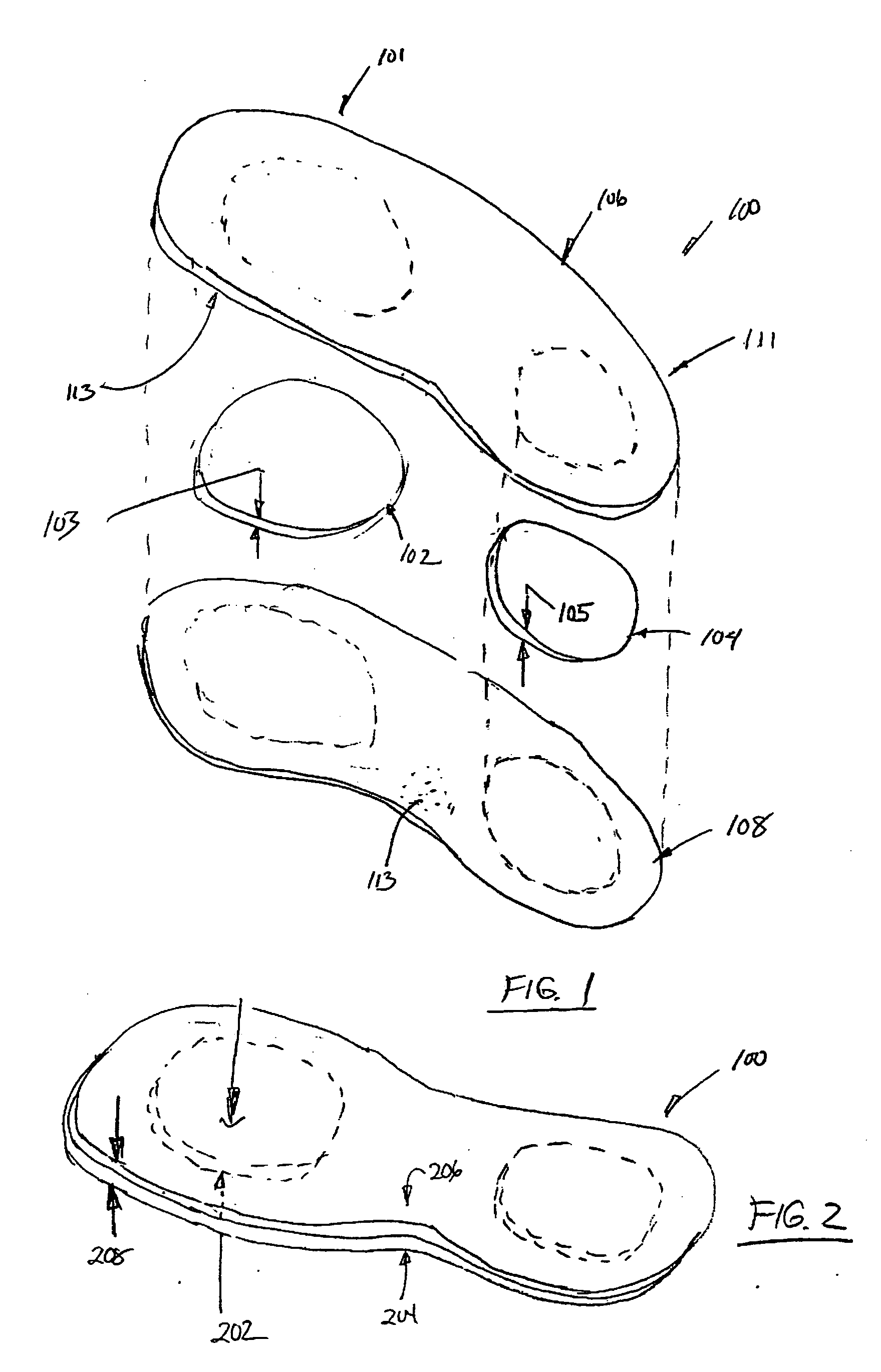

[0012]FIG. 1 illustrates ultra-thin liquid-filled insole interface or assembly 100. Insole interface or assembly 100 comprises at least one ultra-thin liquid-filled cell 102, 104 described in detail in pending U.S. Patent Application entitled ULTRA-THIN LIQUID-FILLED CELL FOR COMFORT ENHANCEMENT, Ser. No. 10 / 142,353 filed on May 8, 2002, which is incorporated by reference in its entirety.

[0013] In the embodiment illustrated, cell 102 is provided proximate first portion 101 of insole 100 to provide comfort to the ball of a foot, while cell 104 is provided proximate second portion 111 of insole 100 to provide comfort to the heel of a foot. One or both of cells 102, 104 can be provided in insole 100. As appreciated by those skilled in the art, the number of cells, as well as their size and shape can be adjusted as needed. Insole assembly 100 further comprises a top substrate 106, which is shaped and sized to fit into various articles of footwear as an insole, or portion thereof. Top s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com