Shelving system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

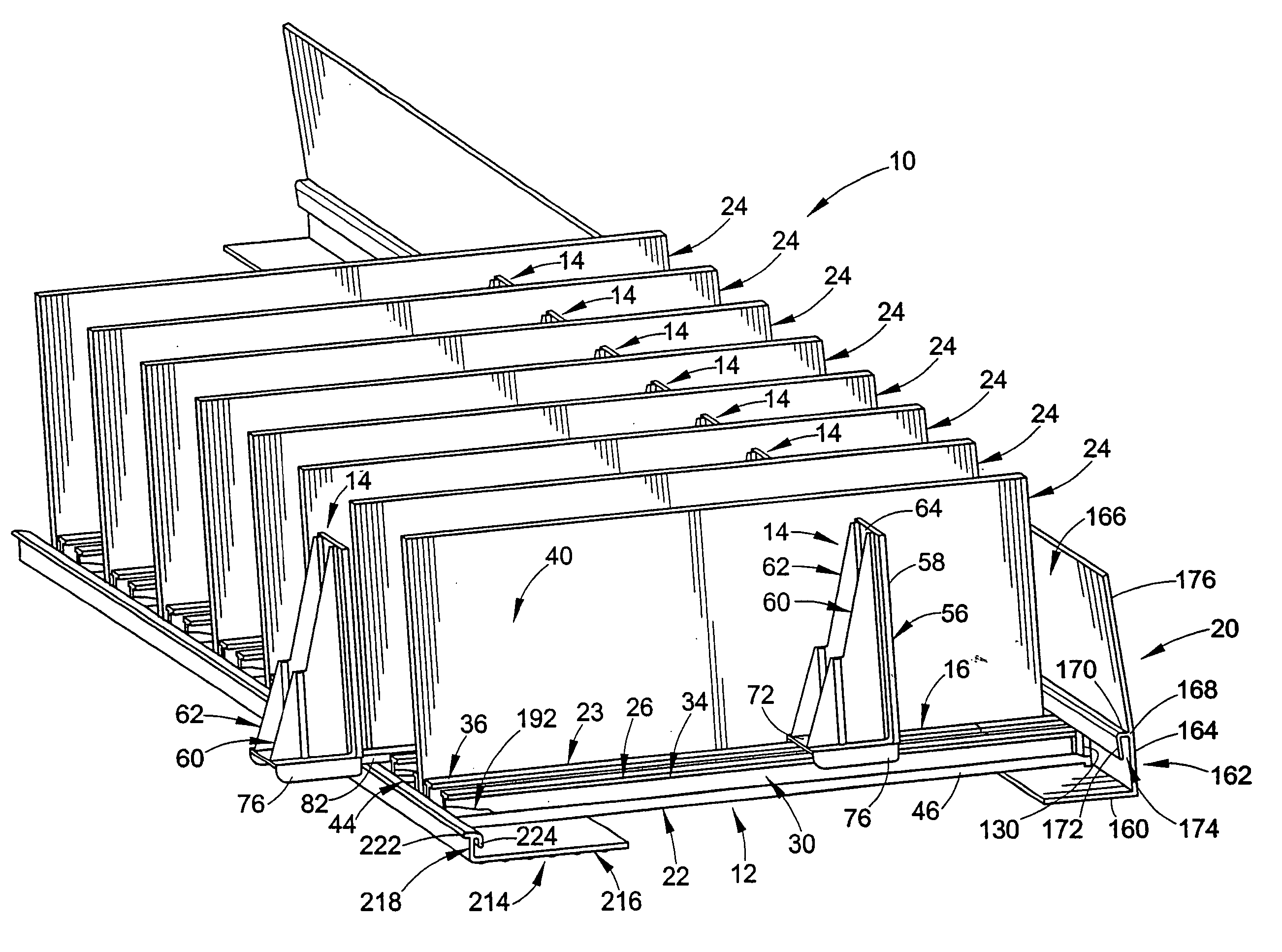

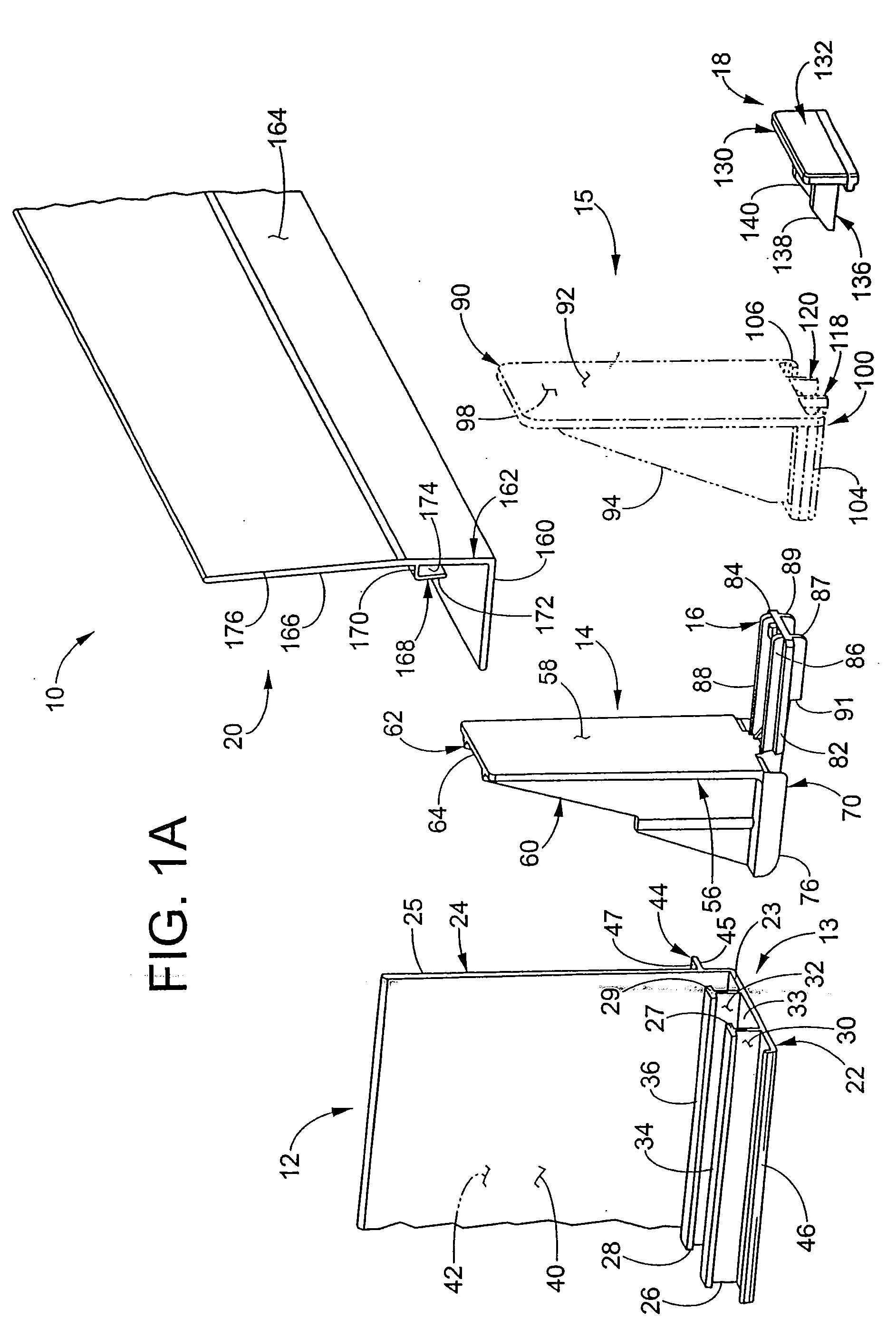

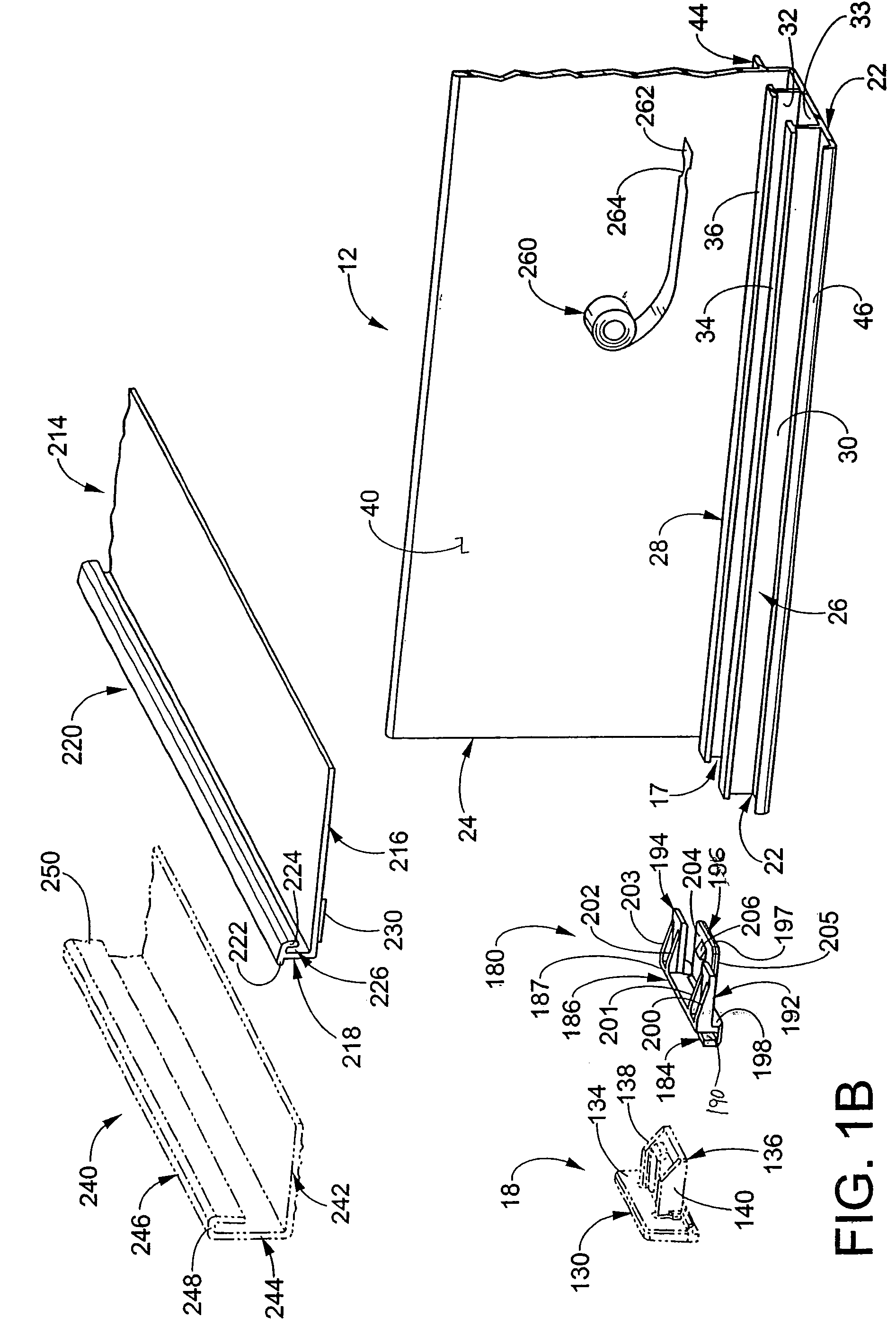

[0041] As shown in FIG. 1A, the paddle 14 includes the foot 16. The paddle 14 further includes a pusher wall 56 with a front face 58 and a pair of gussets 60, 62 which extend rearwardly from a rear face 64. These are generally angled from the top of the pusher wall 56 to a base 70 of the paddle 14. The gussets 60, 62 serve to stiffen the pusher wall 56. The foot 16 extends forward of the pusher wall front face 58. An upper surface (shown in FIG. 2) of the base 70 serves as a spring carrier surface 72. At opposing sides of the spring carrier surface 72 are a pair of outside edges 76 and (not visible) projecting downward generally perpendicular to the spring carrier surface 72. The outside edges are parallel to one another and are spaced to slidably engage, along with an underside or sliding surface 80 of the spring carrier surface 72, the flattened horizontal surfaces 34, 36 of the T-rails 26, 28. The foot 16 extends forwardly transverse to the front face 58 of the pusher wall 56. T...

second embodiment

[0042] As also shown in FIG. 1A, the paddle 15 does not include a foot. However, the paddle 15 does include a pusher wall 90 with a front face 92 and a pair of gussets 94, 96 extending rearwardly from a rear face 98. These generally angle from the top of the pusher wall 90 to a base 100 of the paddle 15. The gussets 94, 96 serve to stiffen the pusher wall 90. An upper surface of the base 100 serves as a spring carrier surface. At opposing sides of the spring carrier surface are a pair of rolled edges 104, 106 projecting downwardly and inwardly. The base 100 also includes a pair of legs 118, 120 extending transverse to a lower or sliding surface 108 of the base 100. The legs 118, 120 are configured to slidably engage the upper surface 33 of the base wall 22 to support and align the paddle 15 along the track 12.

[0043] With continued reference to FIG. 1A, a front end clip 18 for each track 12 is shown. This includes a vertical rectangular front plate 130 with a front face 132 and a rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com