Weather seal construction including a weather-strip

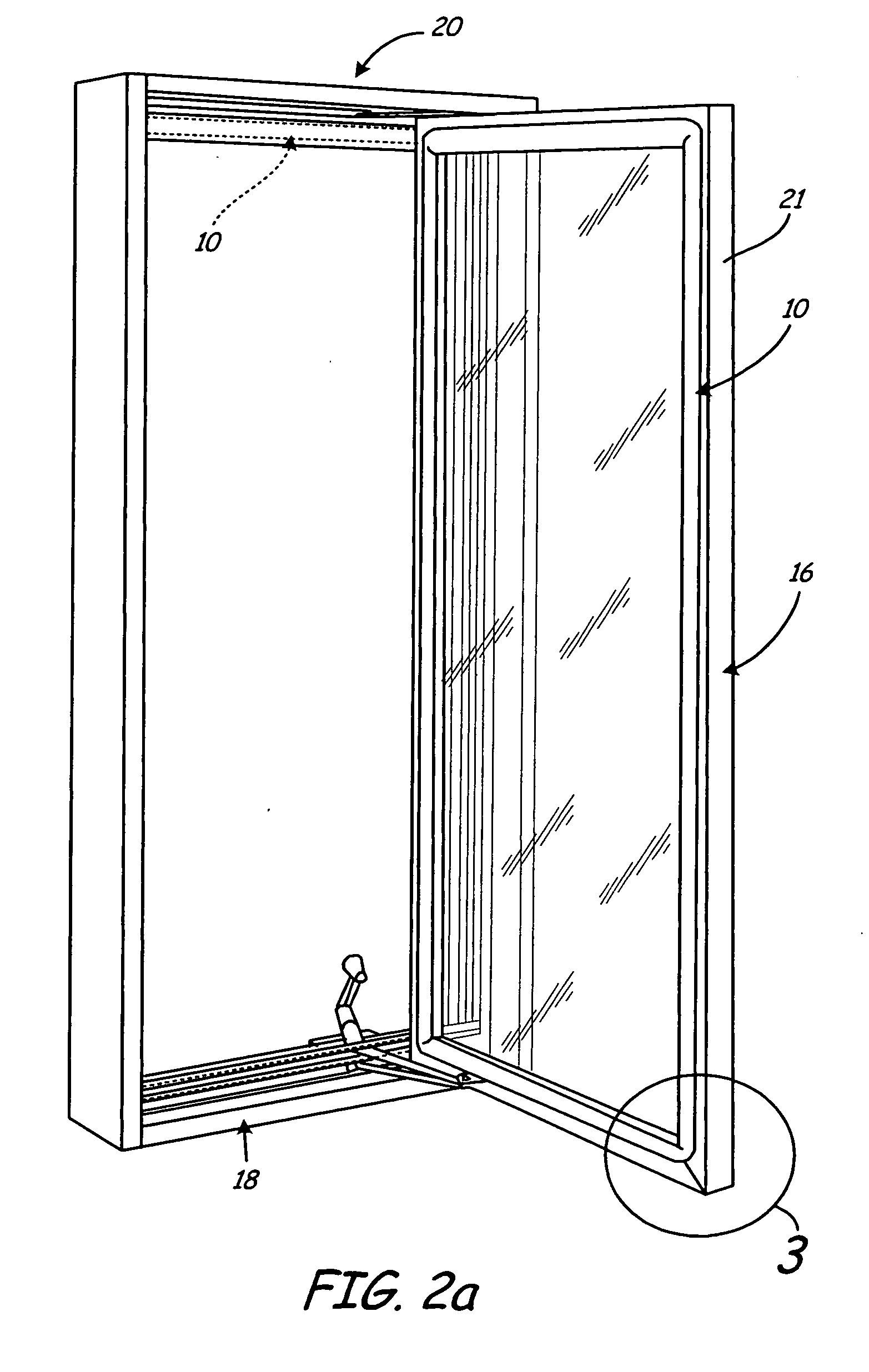

a technology of weather seals and construction, applied in the field of weather seals, can solve problems such as door or window not sealing properly against weather seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment 310

[0028] The weather-strip of the present invention can also be attached to the cover member using an adhesive or through a strip attached to the sealing member that in turn is adhesively attached to the cover member as illustrated in FIG. 6. The embodiment 310 includes a sealing member 312 and an adhesive strip 314 having a backing 316 and a layer of adhesive 318. The embodiment 310 is secured directly to the cover member through the use of the adhesive.

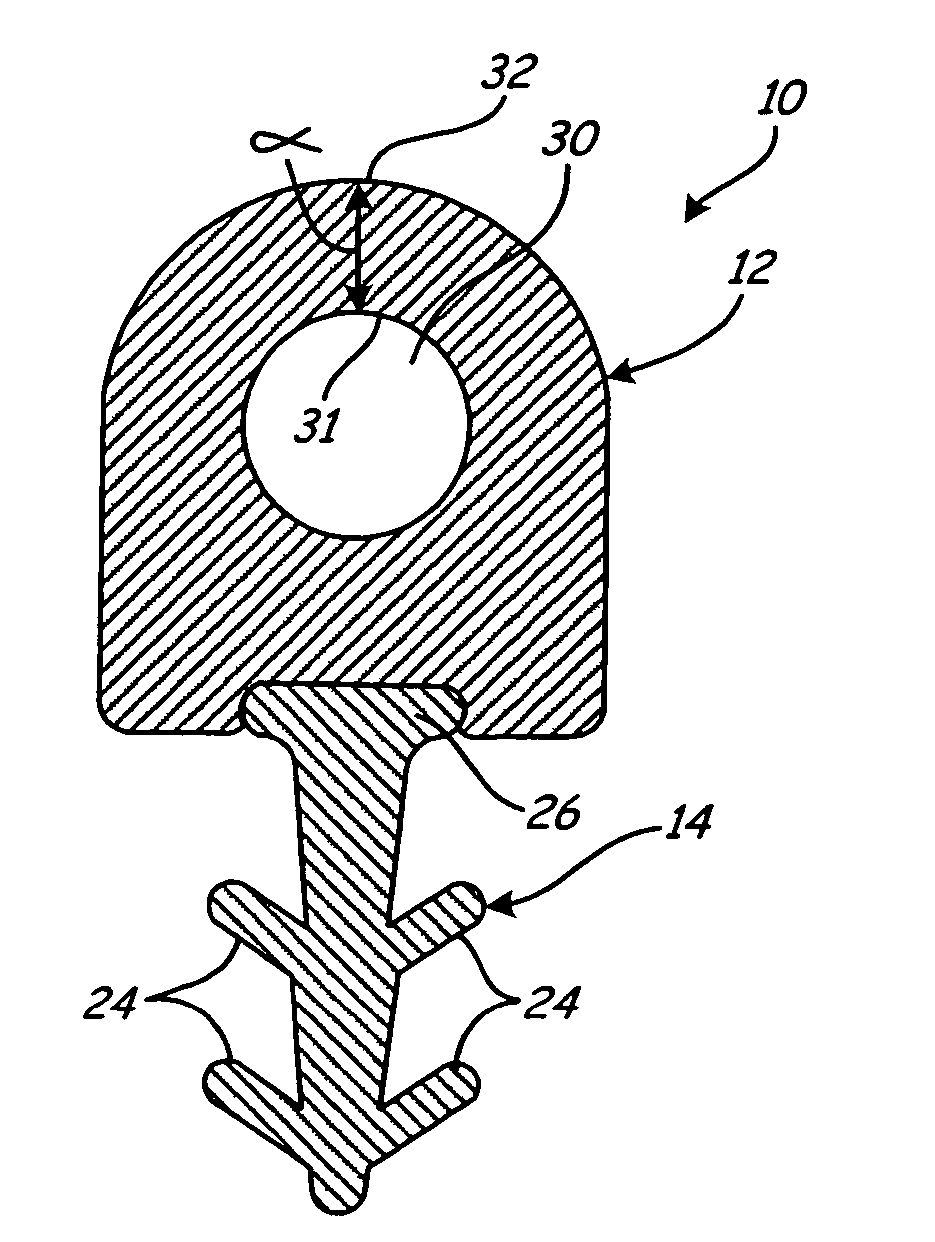

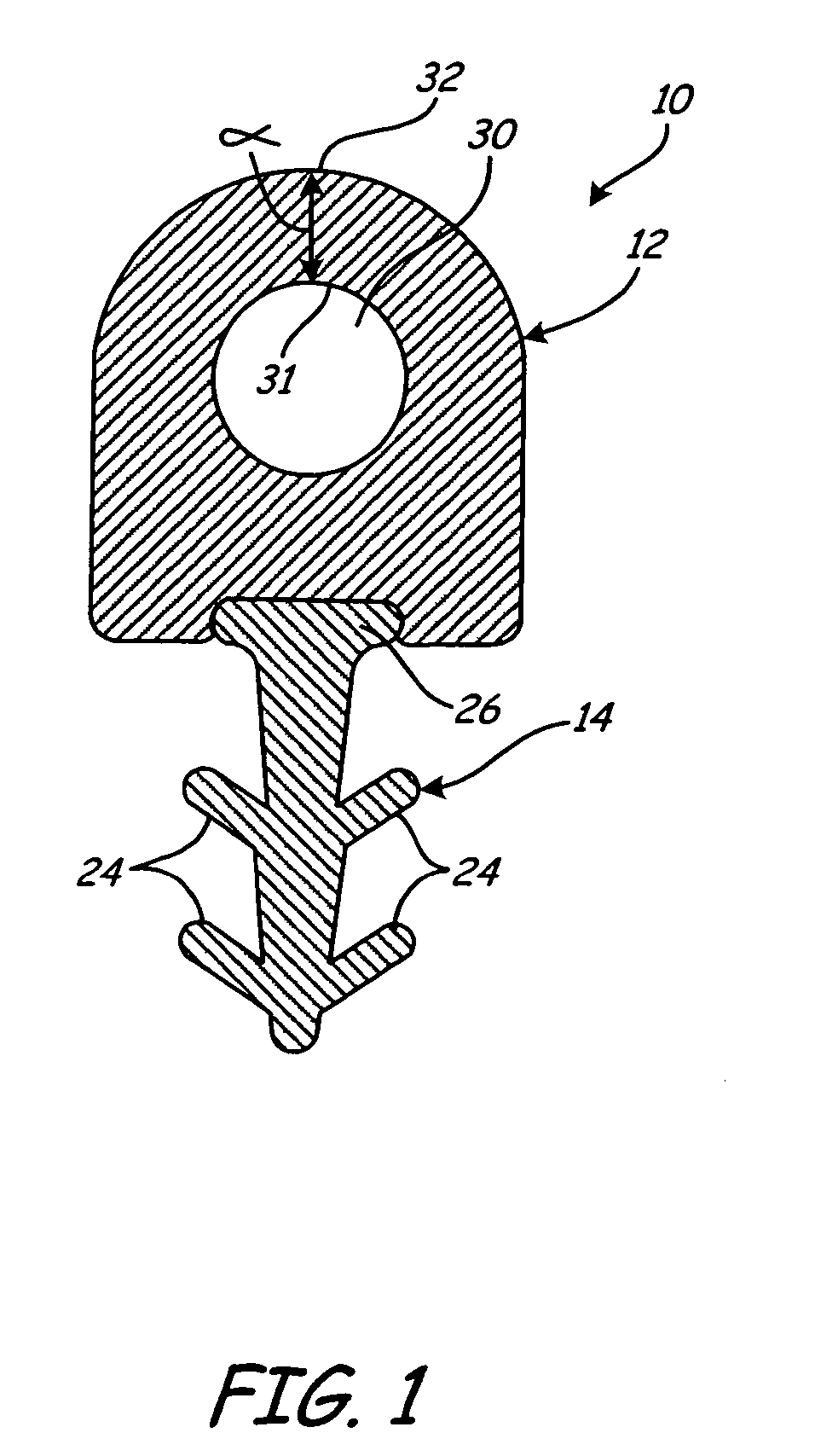

[0029] Another embodiment of the present invention is illustrated in FIG. 4. The embodiment in FIG. 4 includes a sealing member 112 similar to the sealing member illustrated in FIG. 1. The sealing member is attached to an attaching member that has an “L”-shaped cross sectional profile. The attaching member also includes barbs 124 which are positioned in a direction so that the attaching member can be inserted into a kerf (not shown), but resists removal of the attaching member from the kerf once inserted into the kerf. The attaching m...

embodiment 210

[0030] Another embodiment of the present invention is illustrated in FIG. 5. The embodiment 210 includes a sealing member 212 similar to the sealing members discussed with respect to FIGS. 1 and 4. The attaching member 215 includes a leg portion 225 that extends from the cap portion 226 bent in an “L” shaped manner such that the distal end portion 227 is substantially parallel to the cap portion 226. It will be appreciated that the embodiment 210 engages a kerf (not shown) that is located on the surface 90 degrees from the surface from which the sealing portion 212 extends.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angles | aaaaa | aaaaa |

| angles | aaaaa | aaaaa |

| melt temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap