Automated sleeve expander

a sleeve and expander technology, applied in the field of automatic sleeve expanders, can solve the problems of fatiguing the material and/or seams, laborious process of manual sleeve expanders, and tireing the operator's hands and back,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

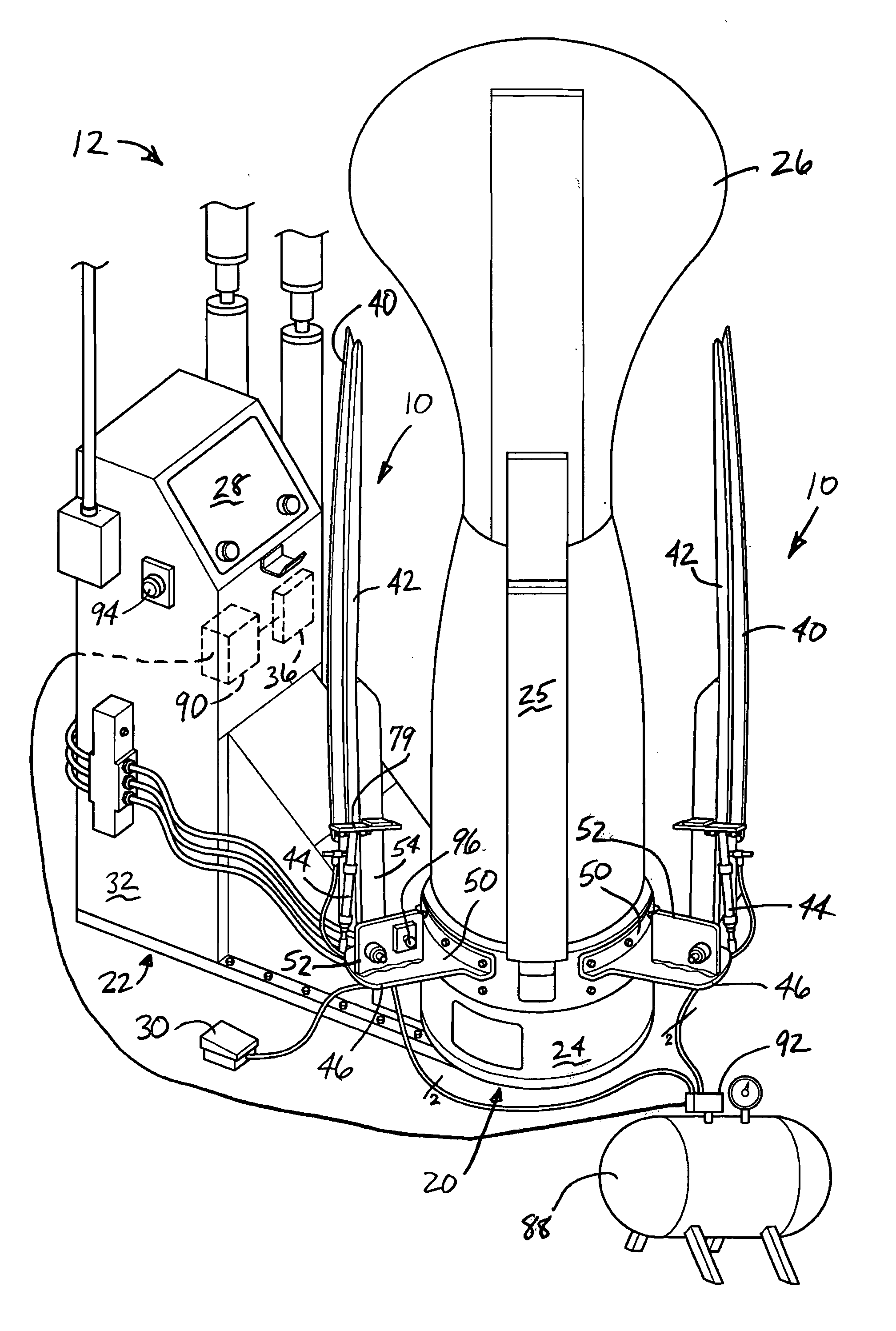

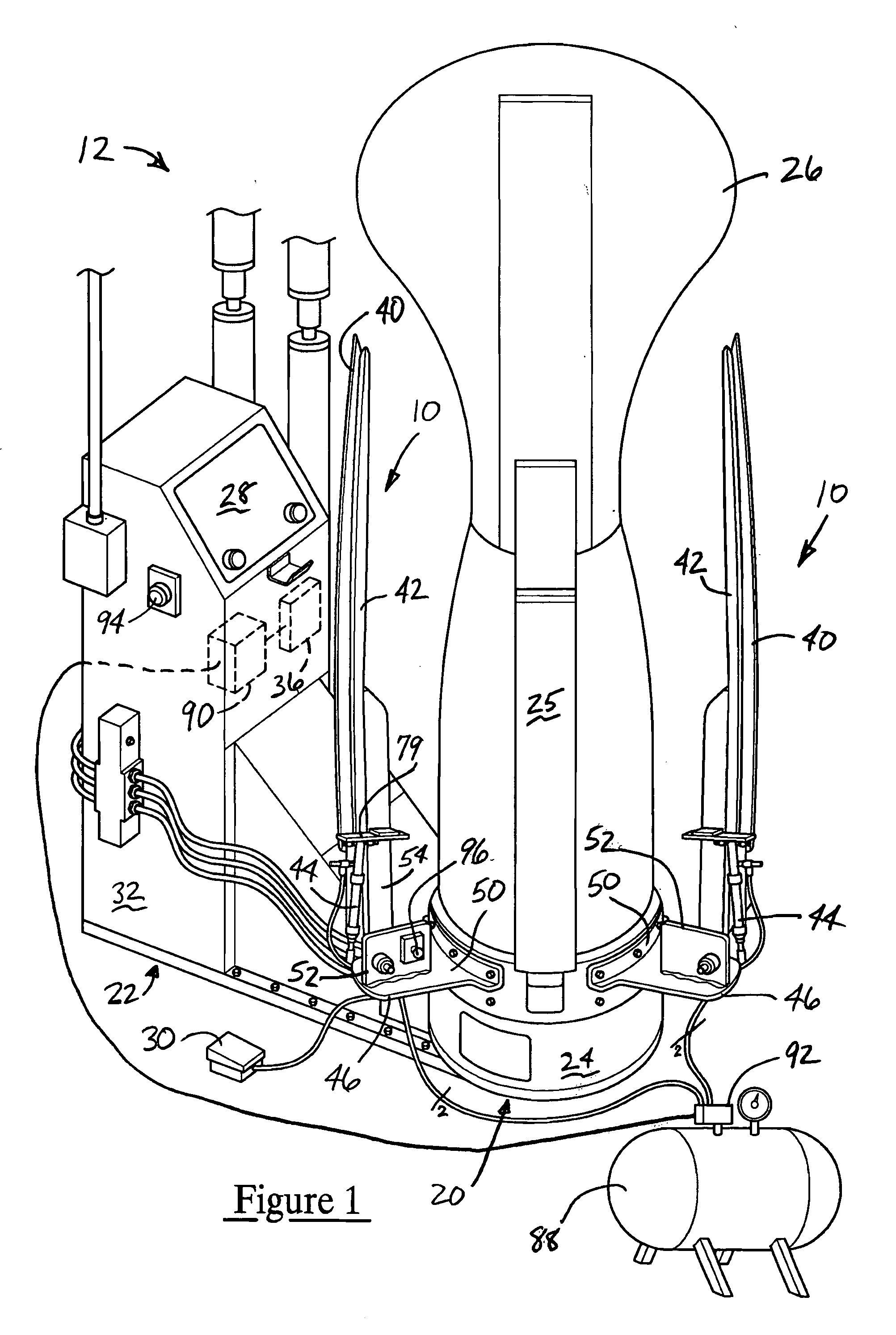

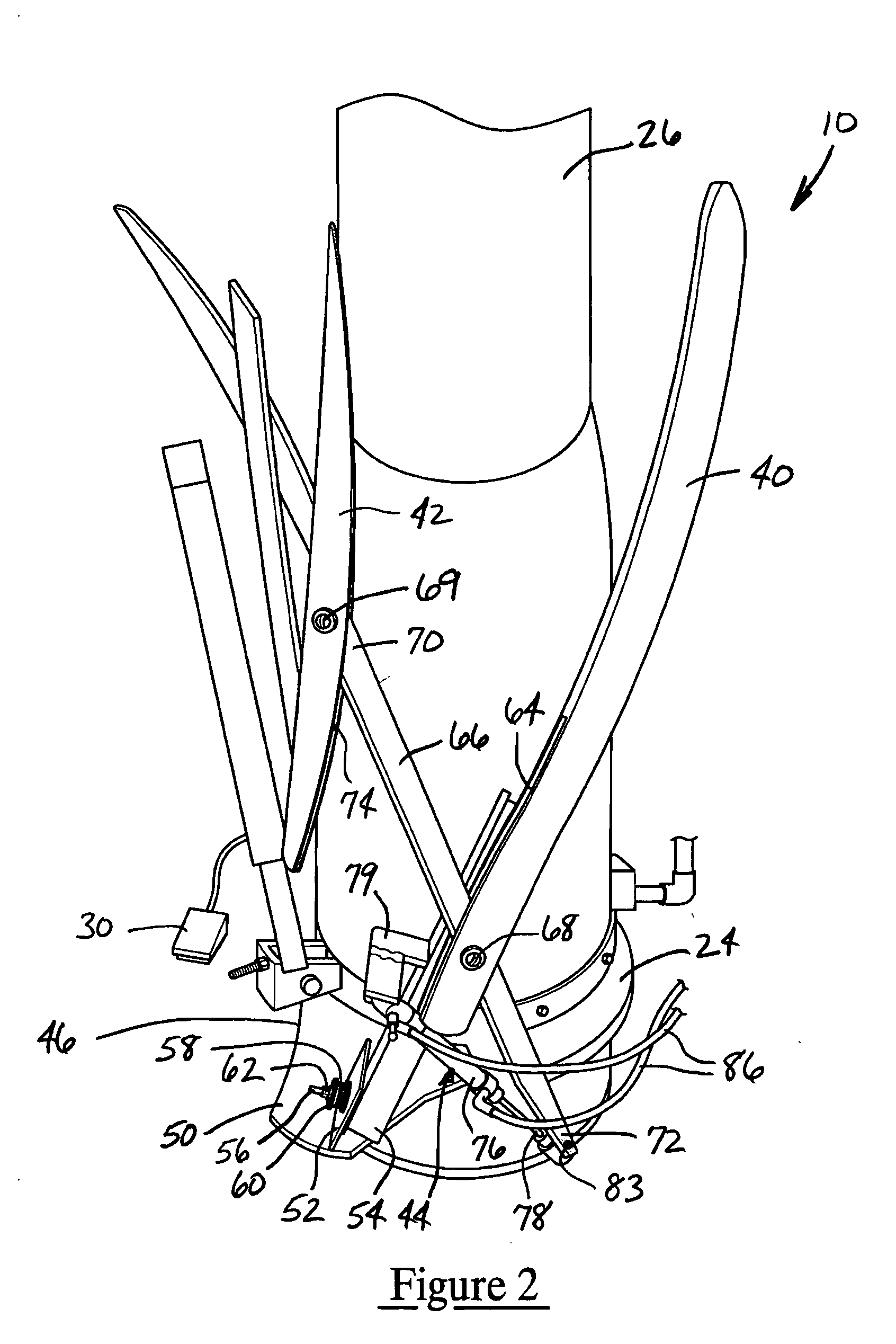

[0013] With reference to FIG. 1, there is shown a pair of automated sleeve expanders 10 for use with a steam treatment machine 12 for stretching or expanding the sleeves on clothing such as a suit coat during steaming. The automated sleeve expanders 10 may be integrated by the original equipment manufacturer into a steam treatment machine 12 or may be retrofitted for use with existing steam treatment machines.

[0014] As commonly known in the art, steam treatment machines 12 are comprised of a frame 20 and a steamer 22. The frame 20 is made from metal such as steel or aluminum and includes a lower portion 24 having a circular shape. The steamer 22 includes a fabric garment support 26, electrical controls 28, a foot pedal 30, a steam generator 32, and a fan (not shown). The fabric garment support 26 is commonly referred to as a suzi and is mounted on the frame 20 to support clothing for steaming. The fabric garment support 26 contains a mesh material to allow steam to pass through it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com