Cap assembly for bottles

a bottle and cap assembly technology, applied in the field of bottle cap assembly, can solve the problems of water leakage from the gap, easy contamination of the cap member b,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

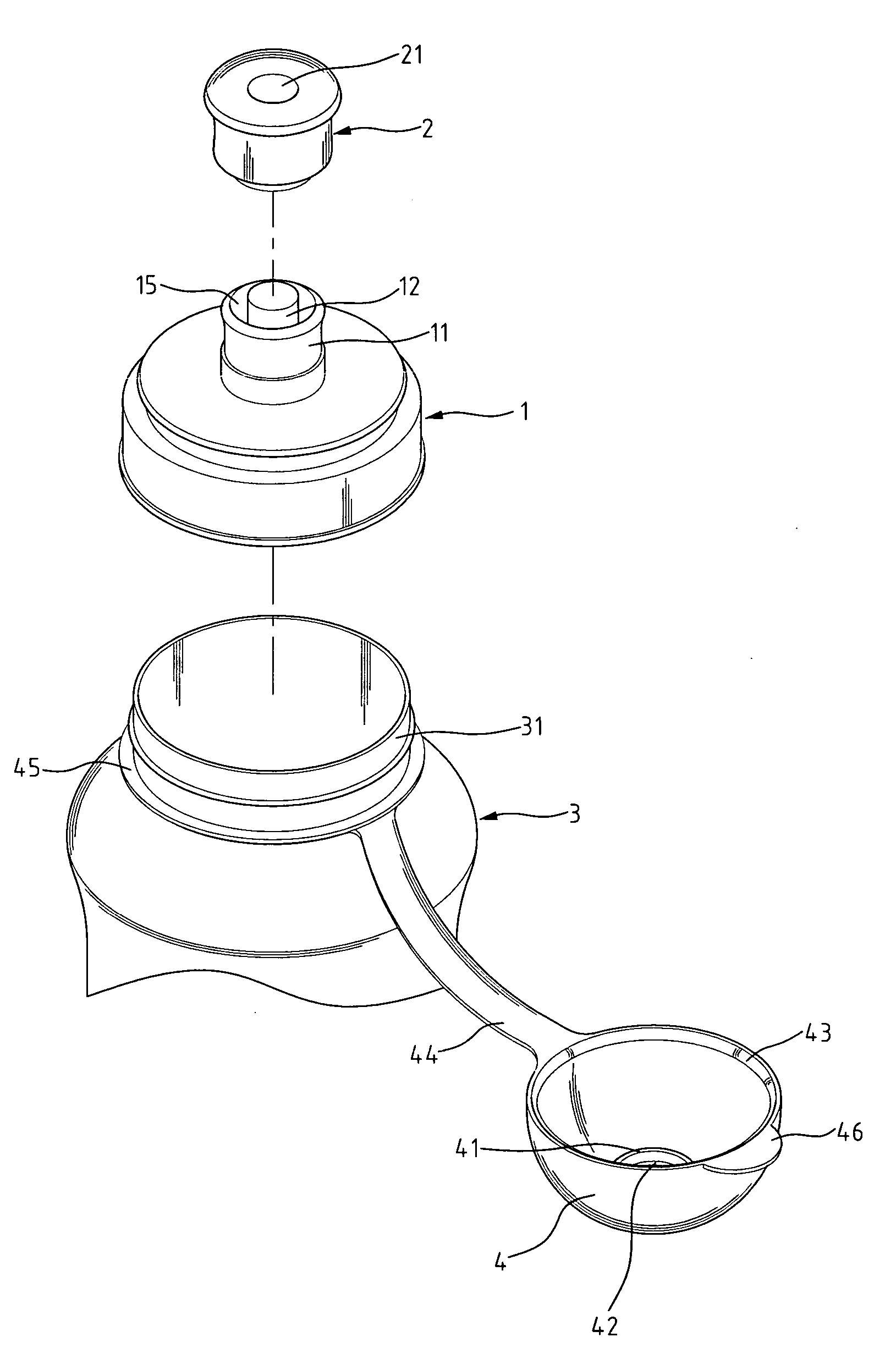

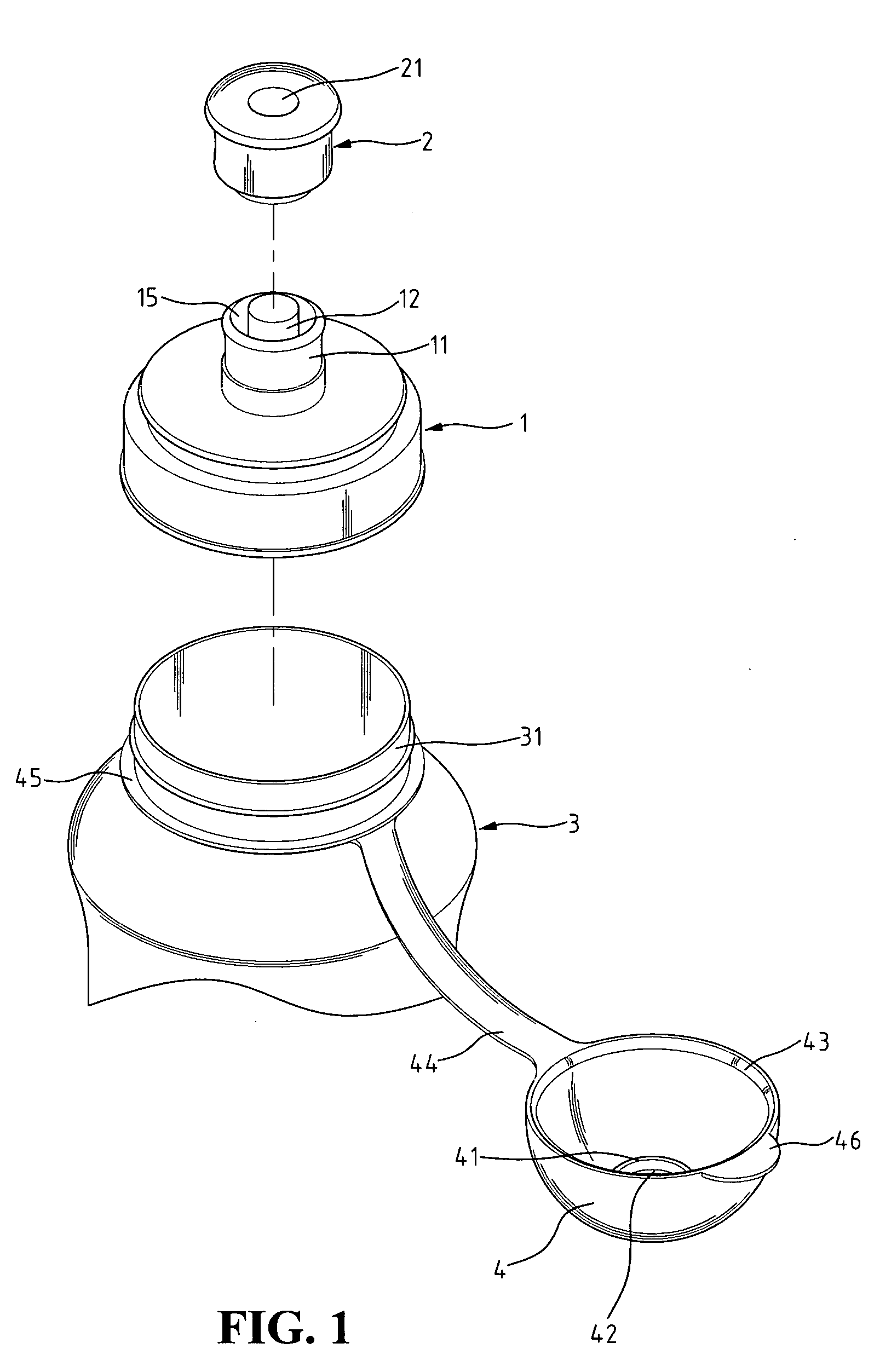

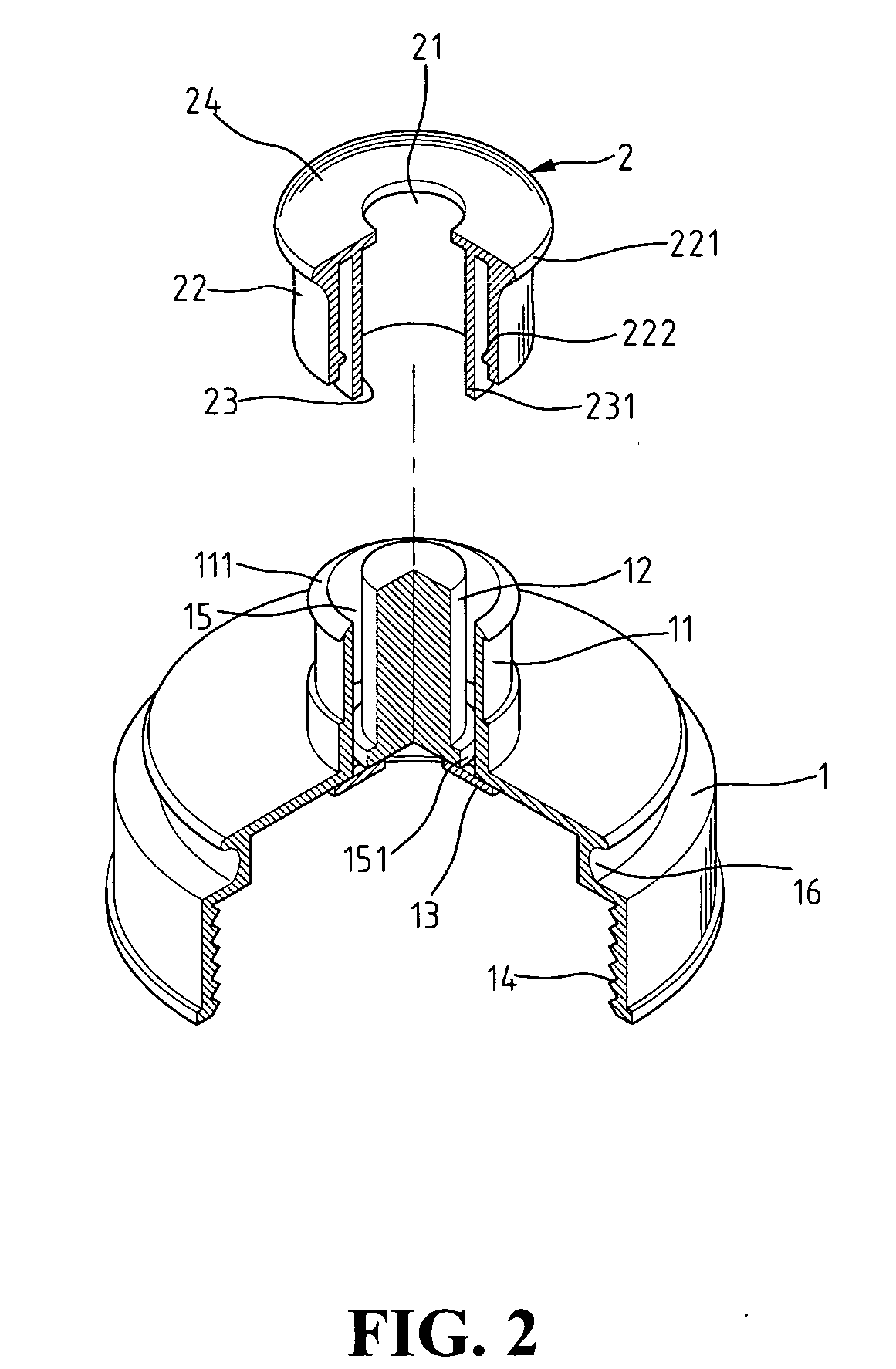

[0019] With reference to the drawings and in particular to FIGS. 1-5, a cap assembly in accordance with the present invention comprises a base member 1 which includes an inner threaded periphery 14 so as to be threadedly connected to an outer threaded periphery 31 of a bottle 3, a tube 11 extending from a top of the base member 1 and a rod 12 located at a center of the tube 11. The rod 12 can be a solid or a hollow rod. A plurality of connection ribs 13 are connected between the rod 12 and an bottom of the tube 11. An annular gap 15 is defined between the rod 12 and an inner periphery of the tube 11. A plurality of apertures 151 are defined between the connection ribs 13, and a top flange 111 extends radially outward from a top end of the tube 11. The top flange 111 has a triangular cross section.

[0020] A cap member 2 has an outer engaging tube 22 and an inner engaging tube 23, and the inner engaging tube 23 shares a common axis with the outer engaging tube 22. A top plate 24 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com