Tooth for an Excavator Bucket

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

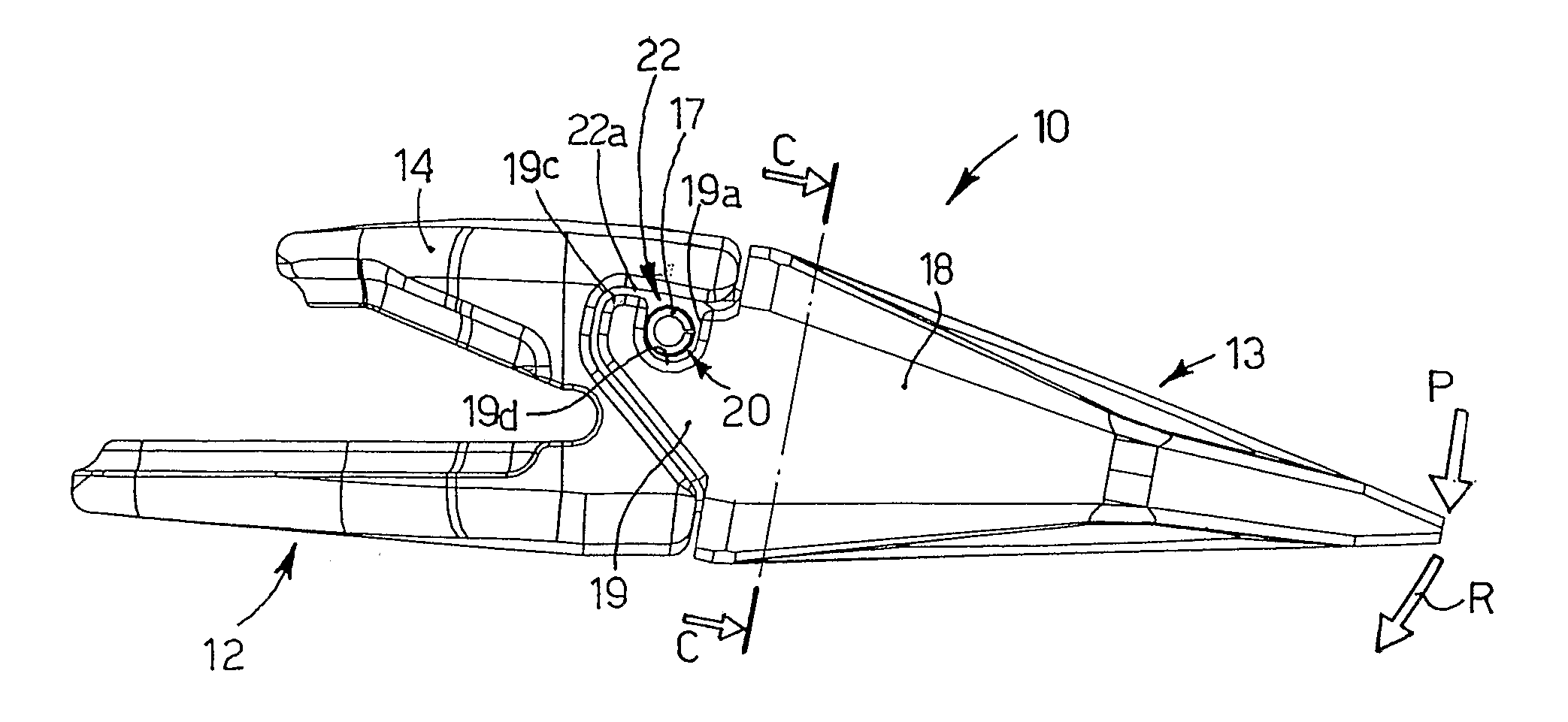

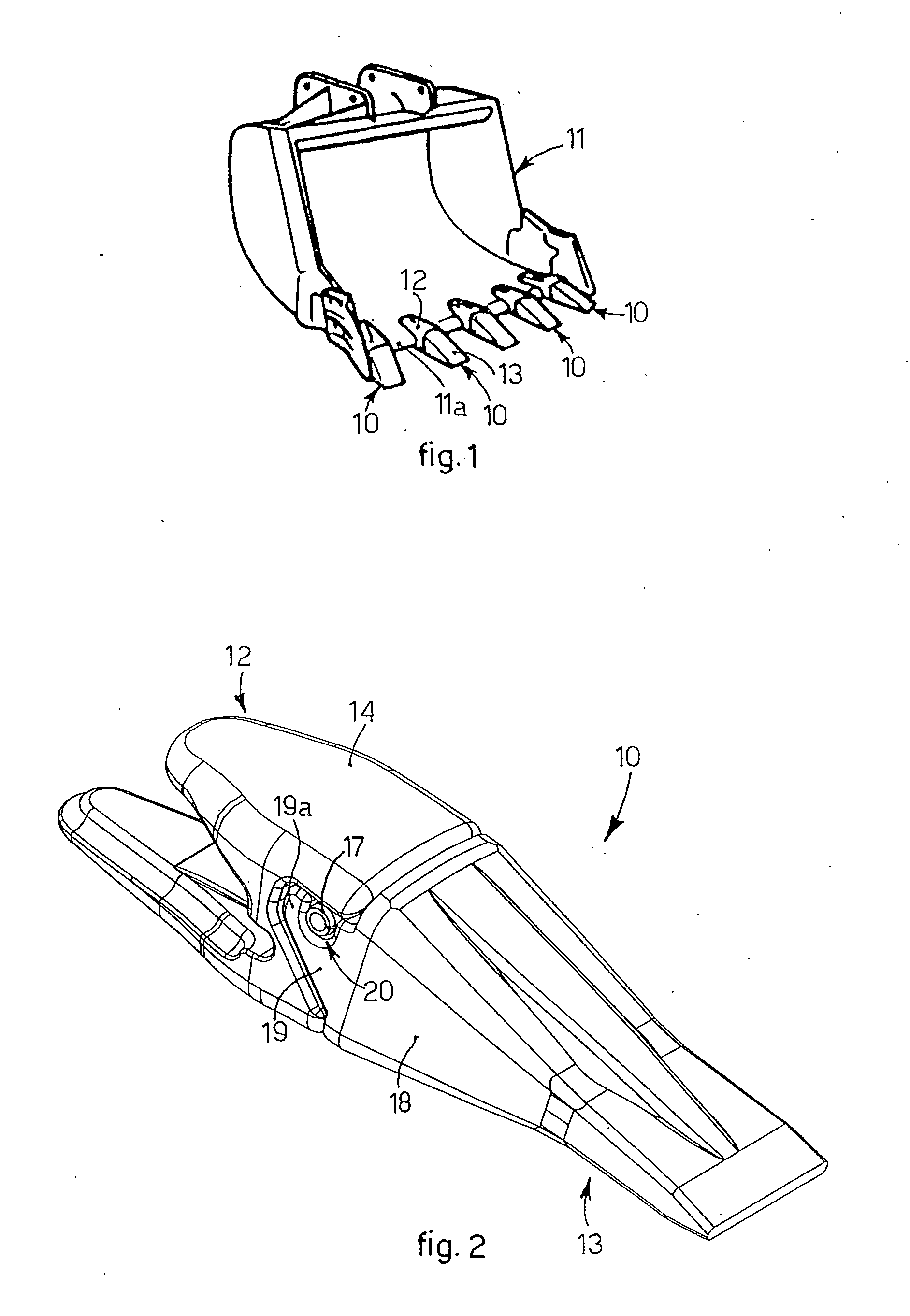

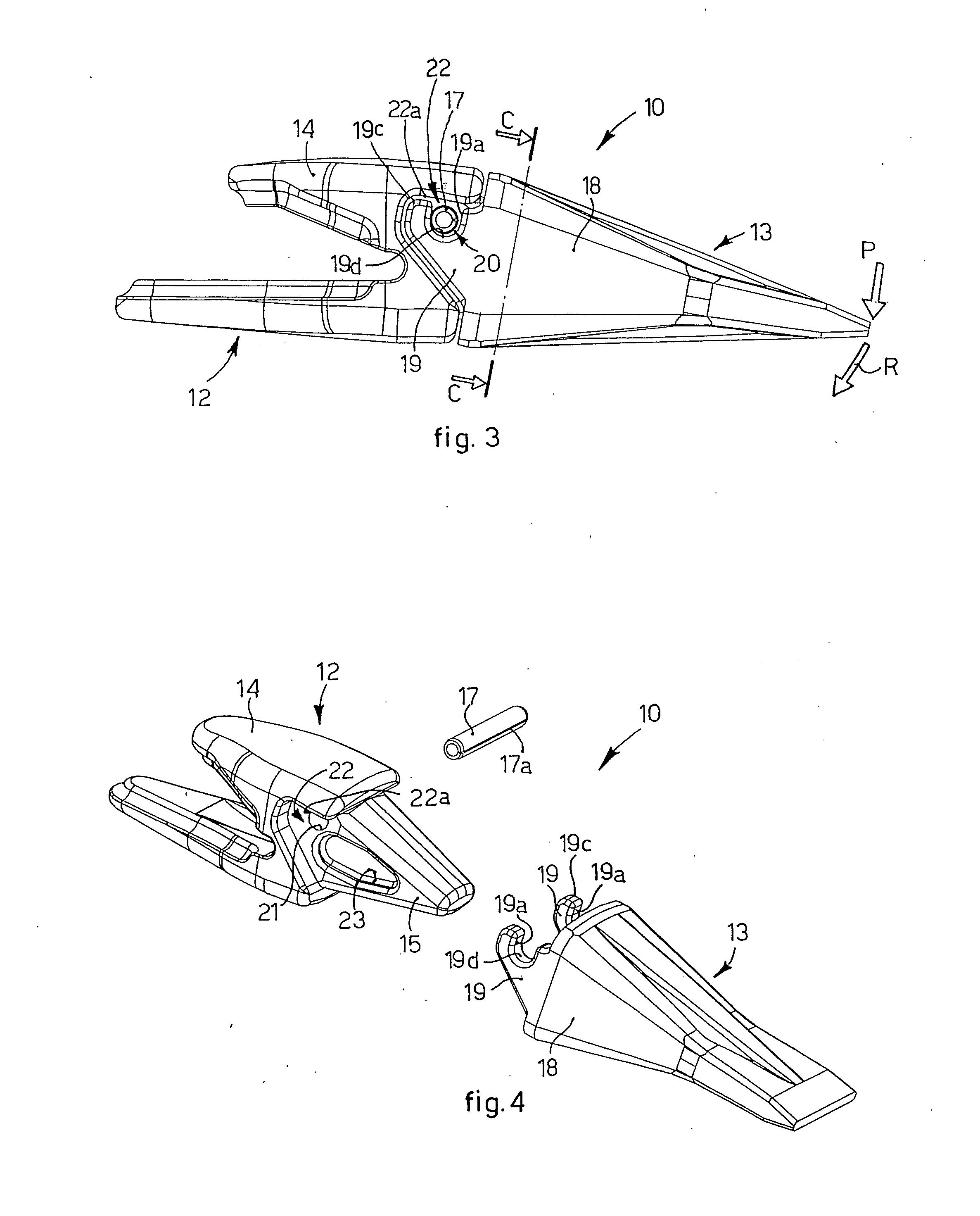

[0035] With reference to the attached drawings, the reference number 10 denotes the tooth according to the invention for buckets 11 of excavators or similar equipment.

[0036] Said tooth 10 comprises a point-bearer 12, able to be attached in a known manner to the lower side 11a of the bucket 11, and a point 13 able to be associated due to their coupling shape at the front of the point-bearer 12 and able to be clamped on the latter by means of a pin 17.

[0037] To be more exact, the point-bearer 12 defines in a single piece a main body 14, at the rear, able to be positioned above the lower side 11a of the bucket 11, and a front protrusion 15, wedge-shaped, able to be inserted in a cavity 16, of mating shape, made on the rear of the point 13, interfering with the inner surface of the cavity 16.

[0038] In the embodiment shown in FIGS. 4 and 8, the front protrusion 15 has a substantially hexagonal transverse section, with two lateral grooves 23.

[0039] In the embodiment shown in FIG. 7, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com