Cigarette-making machine and method

a cigarette and cigarette tube technology, applied in the field of cigarette making machines, can solve the problems of user's first hand fingers getting caught, inadvertent contact of the first hand fingers with the empty cigarette tube, and non-negligible amount of force required to fill the cigarette tube,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

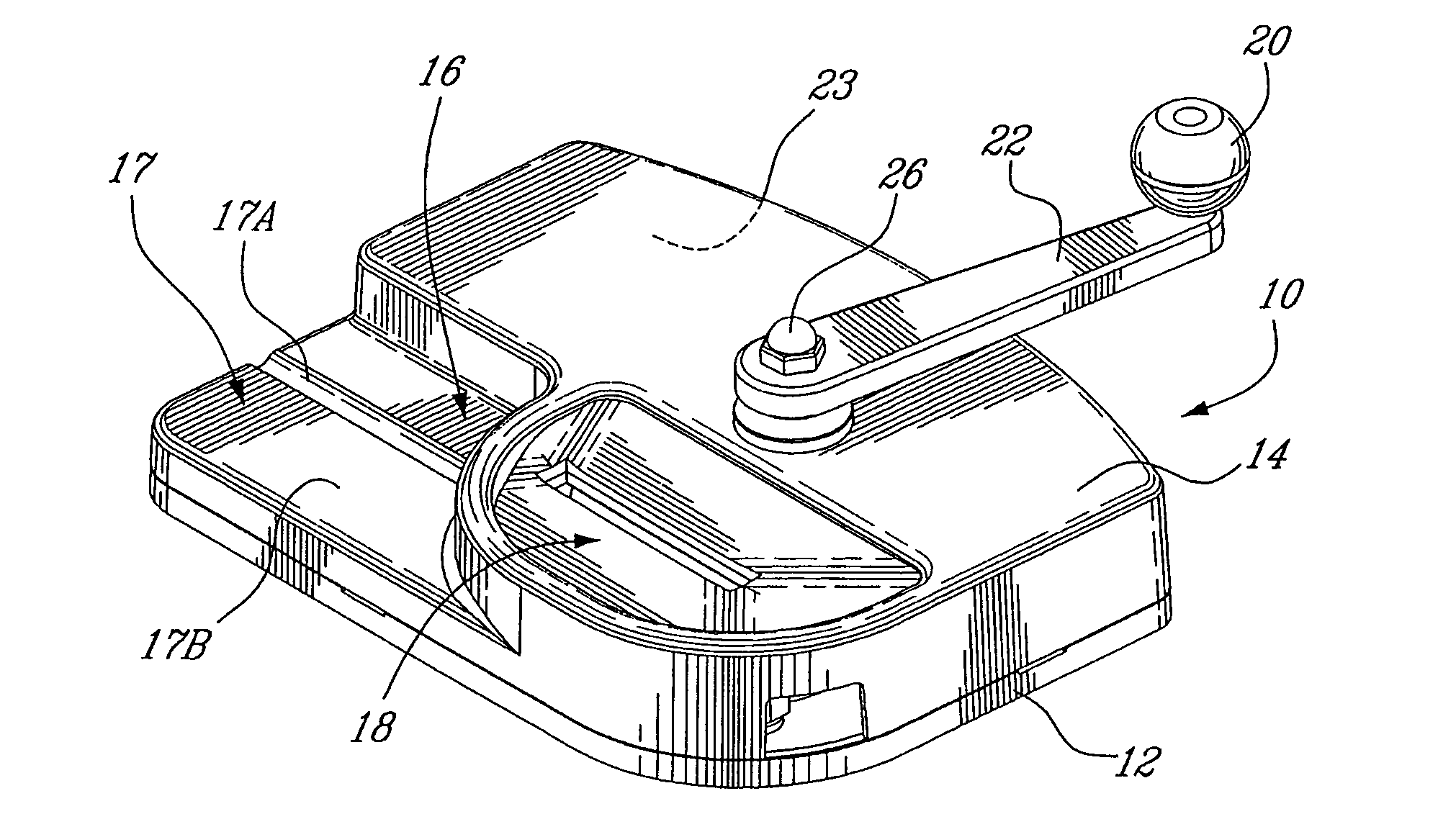

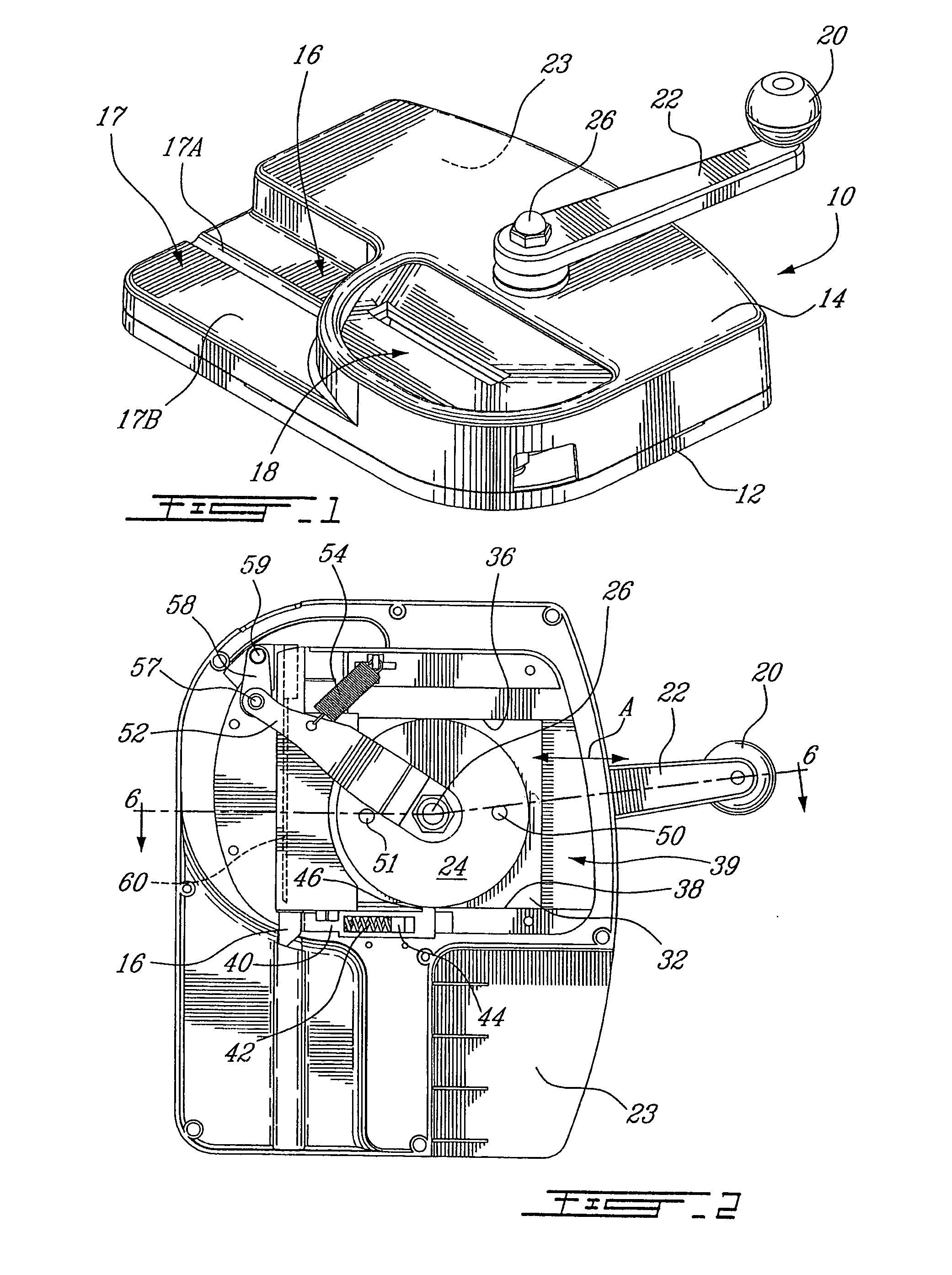

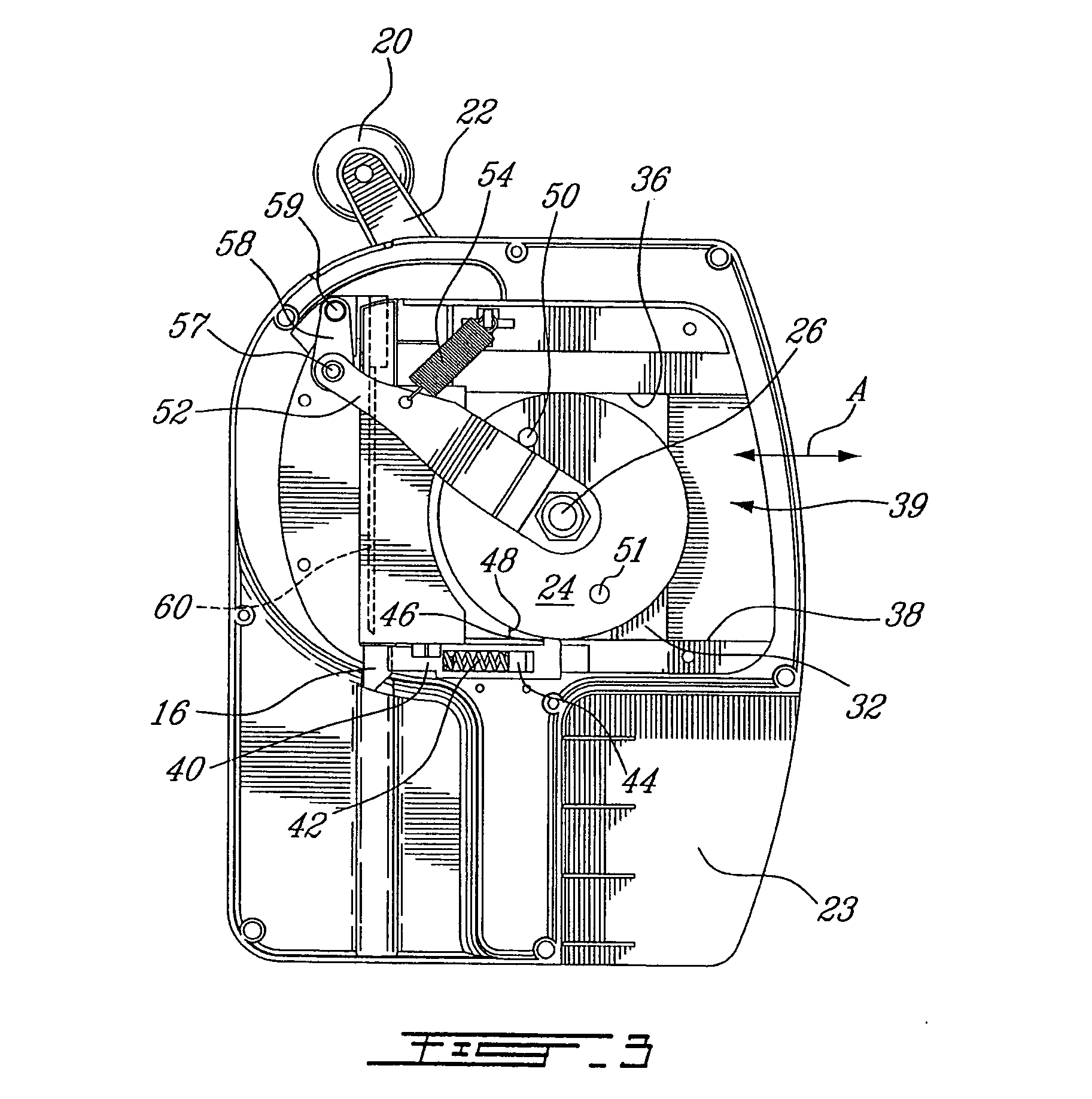

[0024]Referring now to the drawings, a cigarette-making machine is generally indicated by the numeral 10 in FIG. 1. From an exterior viewpoint, the cigarette-making machine 10 has a base plate 12, a casing 14, a cigarette tube nipple 16, a cigarette / tobacco receptacle 17, a tobacco trough / slot 18, a handle 20, a handle drive 22, and a grasping surface 23.

[0025]The base plate 12 is the interface between a support surface and the cigarette-making machine 10. The base plate 12 supports a remainder of the cigarette-making machine 10. The base plate 12 typically has cushions (not shown) on a bottom surface, which cushions are of a resilient anti-slip material. This ensures that the machine 10 stays in place on a support surface, and that the base plate 12 of the machine 10 does not damage the support surface.

[0026]The casing 14 forms the outer shell of the cigarette-making machine 10, and accommodates an internal mechanism of the machine 10.

[0027]The cigarette tube nipple 16, as best sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com