Three-Piece Grip Safety

a three-piece, grip technology, applied in the field of handgun grip safety, can solve the problems of design, design, and unavoidable pressure upward on the underside of the beavertail portion, and achieve the effects of improving the safety of the grip, and increasing the positive interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]With reference now to the drawings, the preferred embodiment of the two-piece grip safety is herein described. It should be noted that the articles “a”, “an”, and “the”, as used in this specification, include plural referents unless the content clearly dictates otherwise.

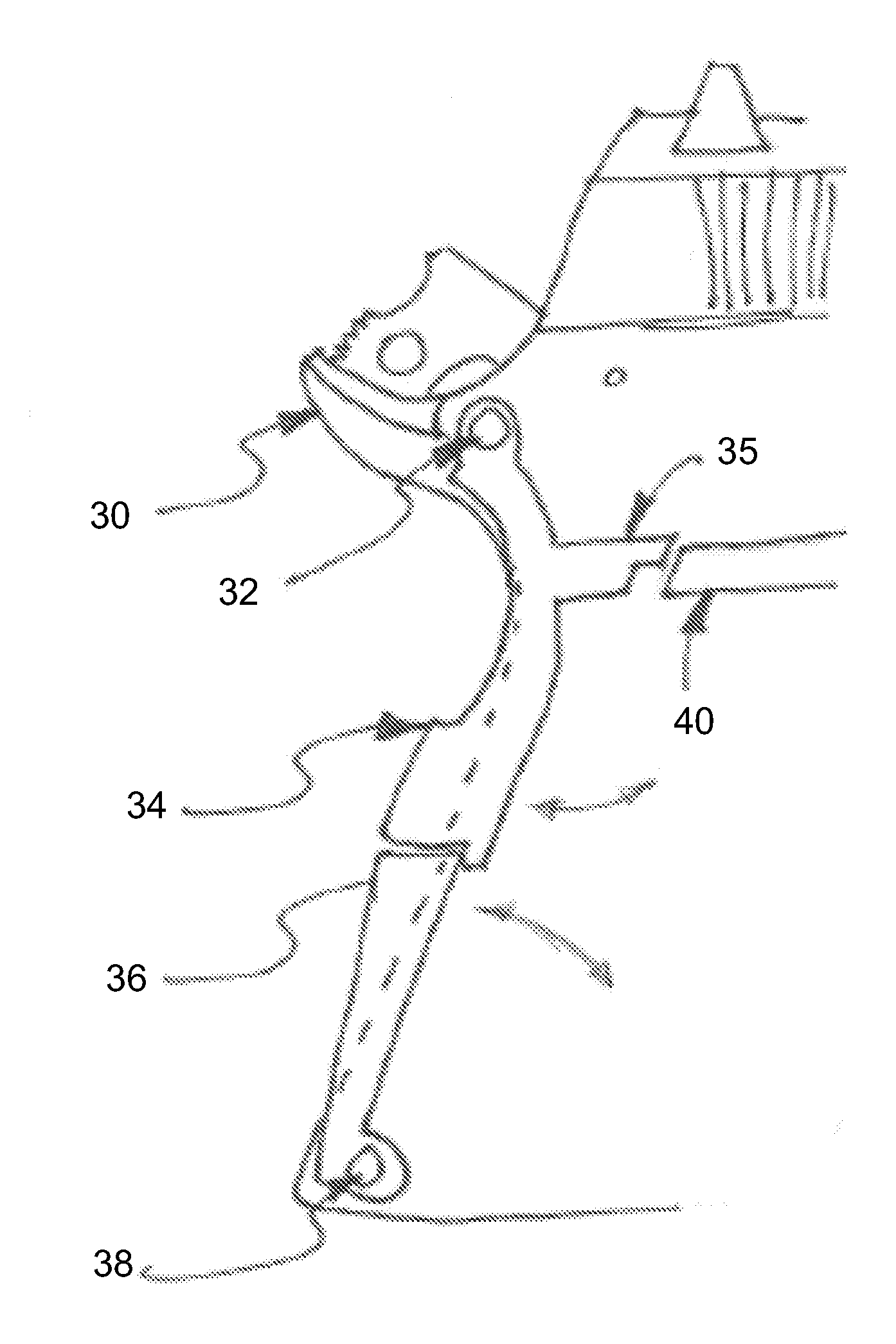

[0018]With reference to FIGS. 3 and 4, the grip safety comprises a fixed main body 30, ideally of the beavertail style, and an adjacent pivoting member 34 mounted upon an upper pivot point 32. Pivoting member is generally located on the right hand side of the main body 30, though appropriate configurations of weapons would allow a left hand side mounting. Pivoting member 34 may also have an expended region or pad to further increase hand contact and depressive action. Extending into the firearm from the pivoting member 34 is a blocking arm 35 which engages trigger bow 40 and prevents firing of the weapon. Pivoting member also interfaces with pivoting base member 36 hinged on lower pivot point 38. These two mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com