Fire damper

a damper and fire technology, applied in the field of fire dampers, can solve the problems of adversely affecting the time period of the louver and thereby the damper, and achieve the effect of reducing the damage of the fir

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

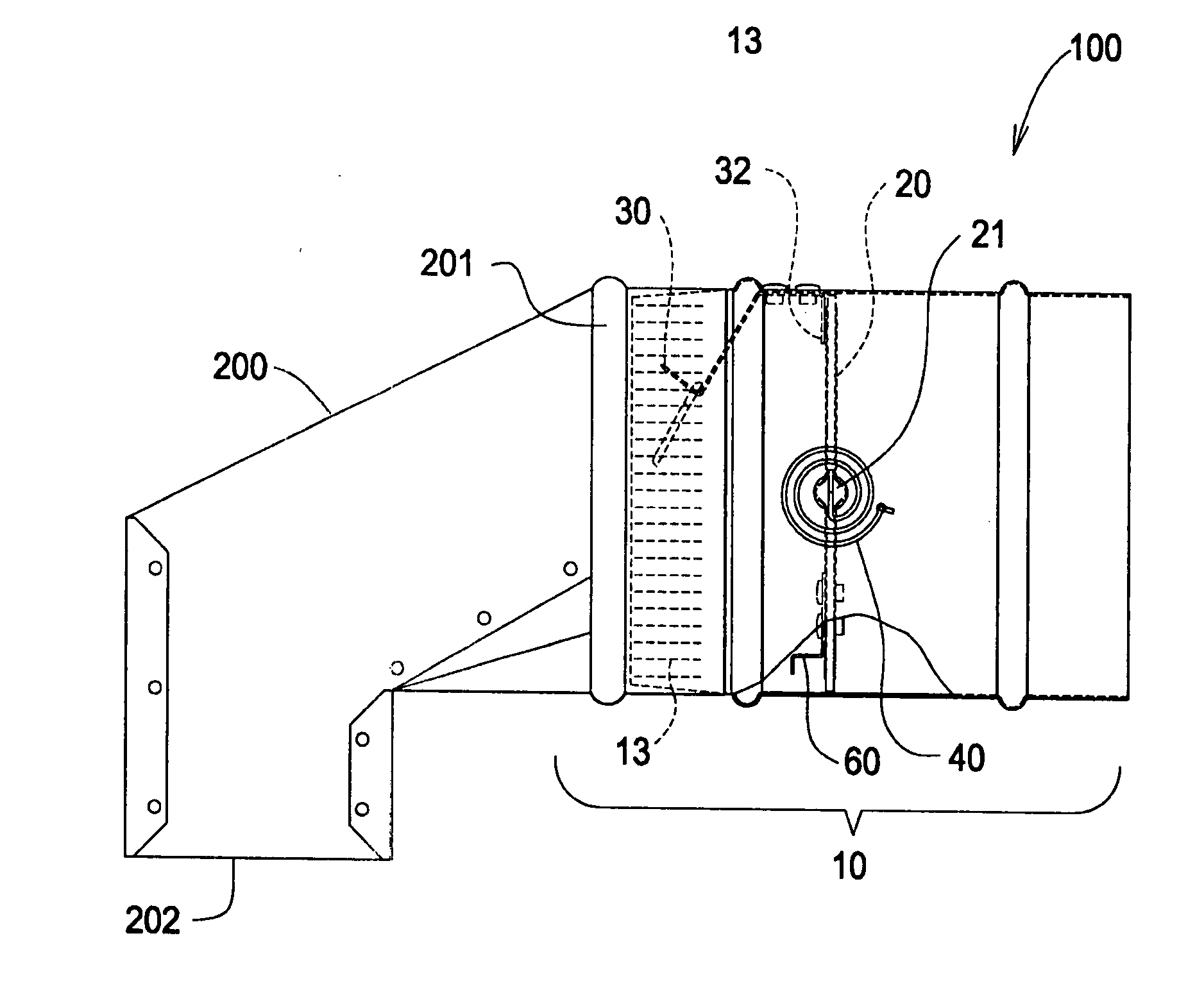

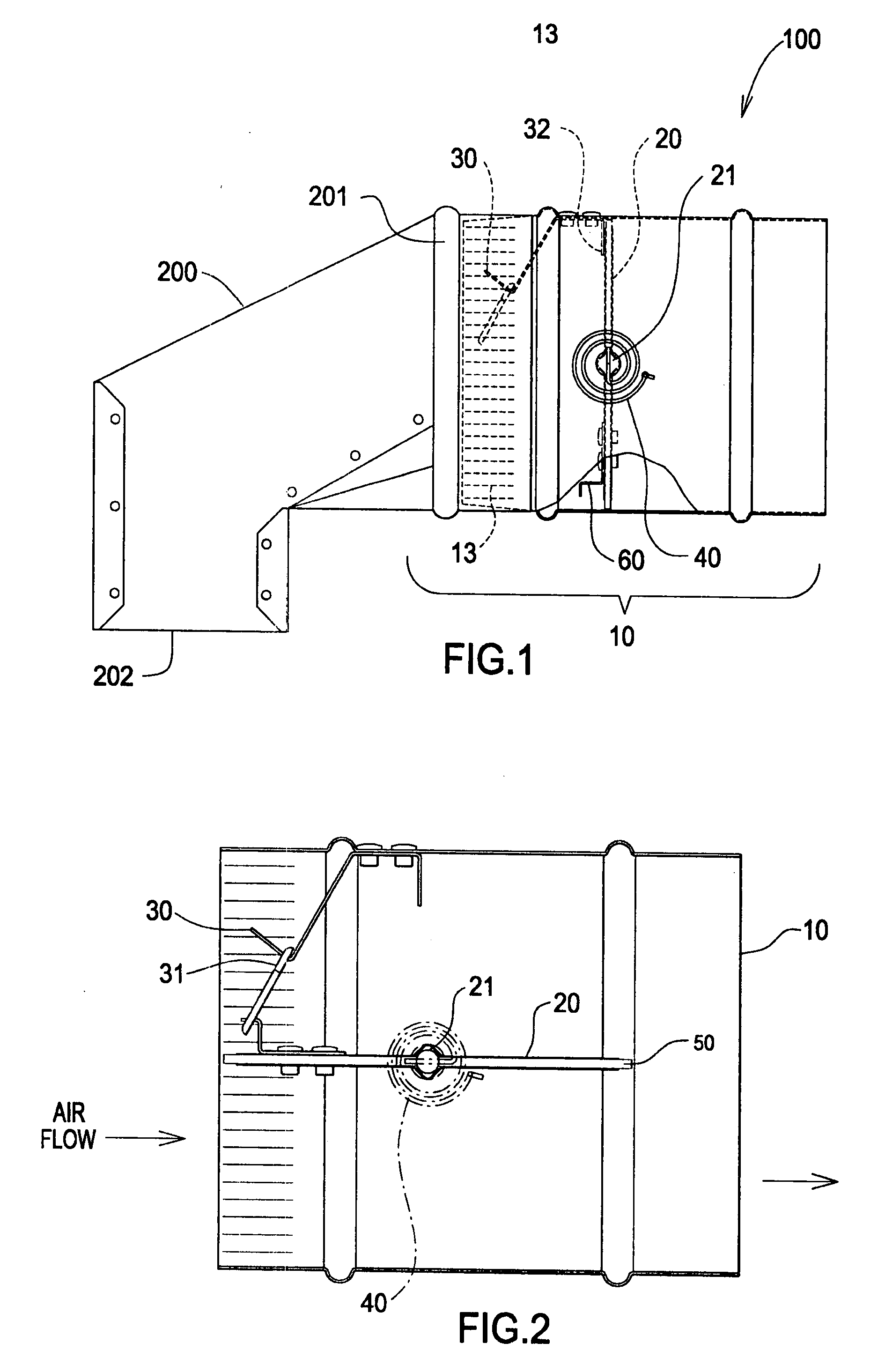

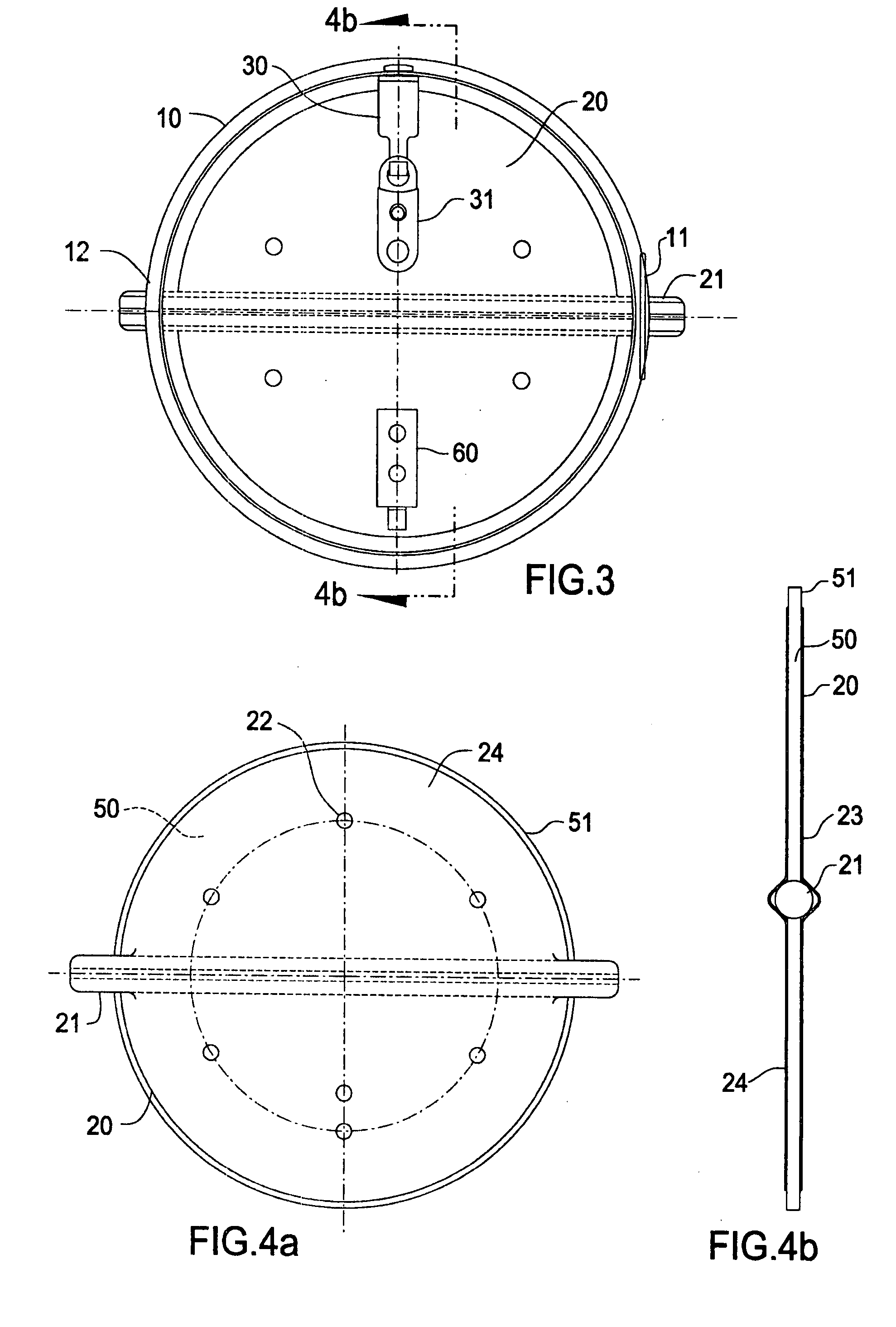

[0017]FIG. 1 is a side view of the fire damper. Fire damper 100 comprises a housing 10. Housing 10 comprises metallic ductwork known in the art, for example, galvanized 22 gauge. In the present embodiment, the housing is circular.

[0018]Disposed within housing 10 is louver member 20. Louver member 20 is mounted to a shaft 21. Shaft 21 rotates within housing 10. Rotation of shaft 21 allows louver member 20 to pivot between an open position and a closed position.

[0019]Member 60 is attached to louver member 20 and is used to connect louver member 20 to temperature sensitive connector 31, see FIG. 2.

[0020]Louver member 20 is shown in the closed position in FIG. 1. In the closed position louver member 20 provides a substantially gas tight seal for a predetermined temperature, and at a differential pressure of up to 15 inches of water.

[0021]Biasing member 40 is engaged between shaft 21 and housing 10. Biasing member 40 biases louver member 20 toward the closed position as is shown in FIG. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com