Beverage carton

a beverage carton and carton body technology, applied in the field of beverage cartons, can solve the problems of increasing the amount of material required for strengthening, requiring a large space for conventional beverage cartons, so as to achieve convenient storage and flattening, and reduce material waste. the effect of was

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

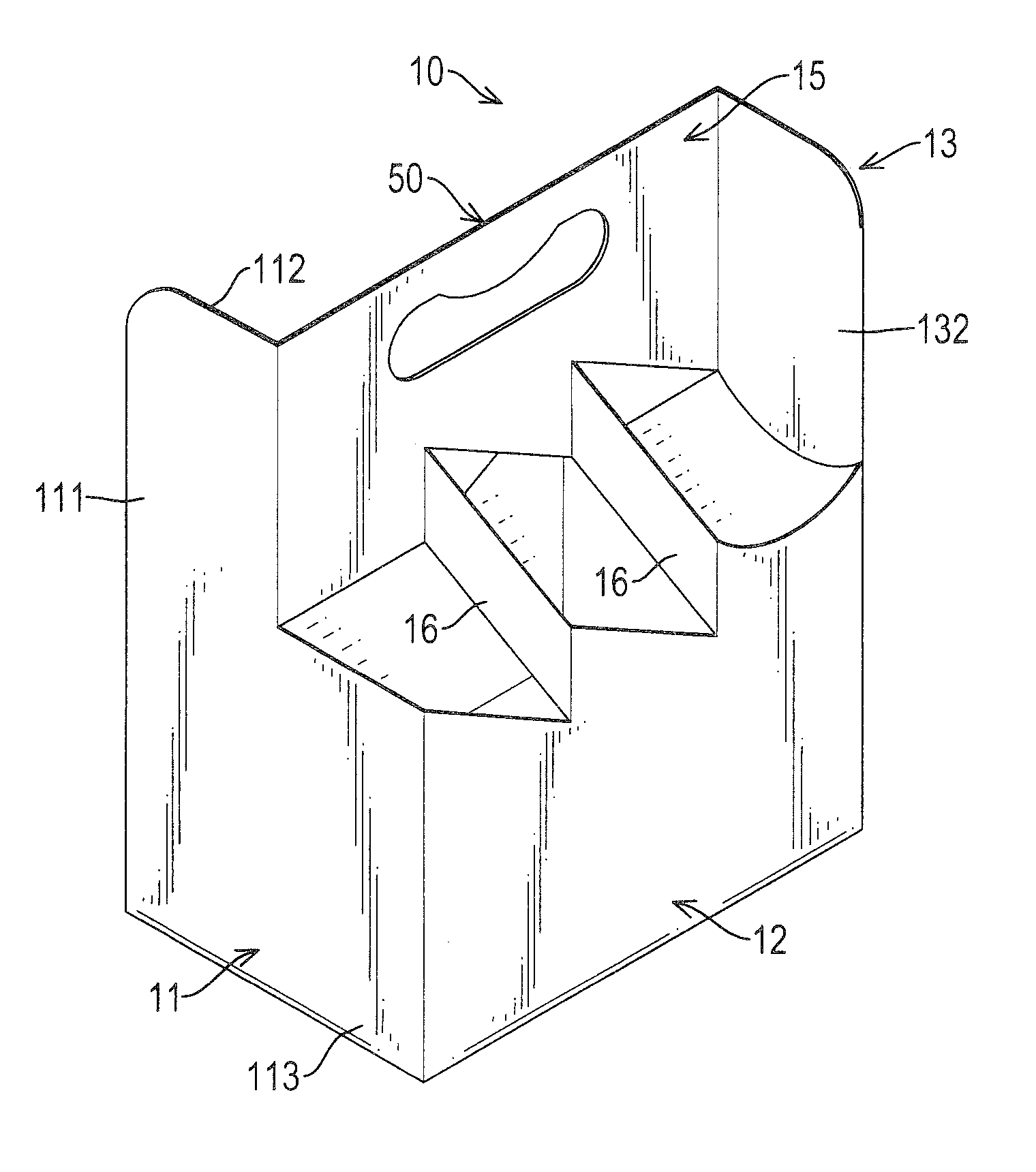

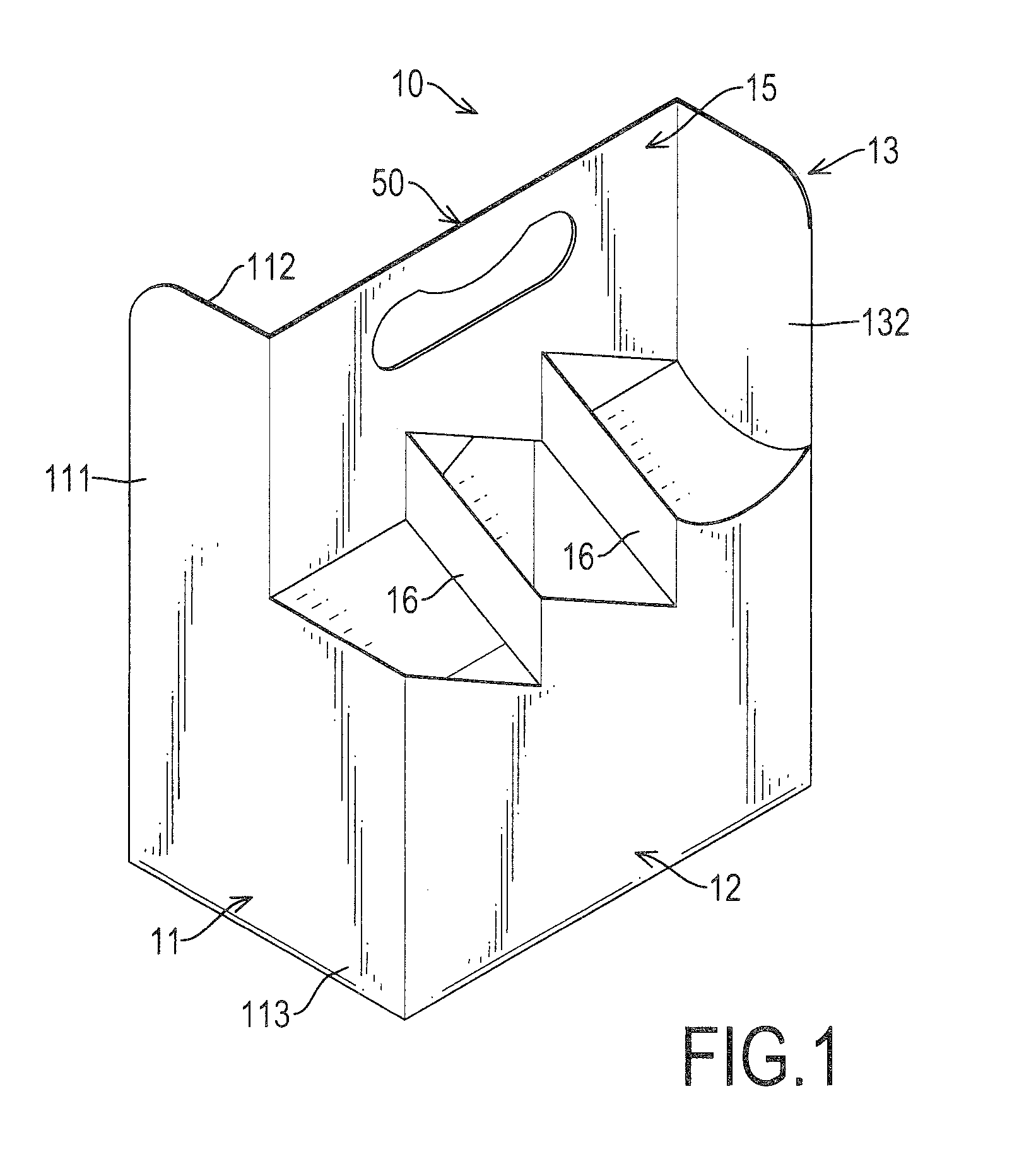

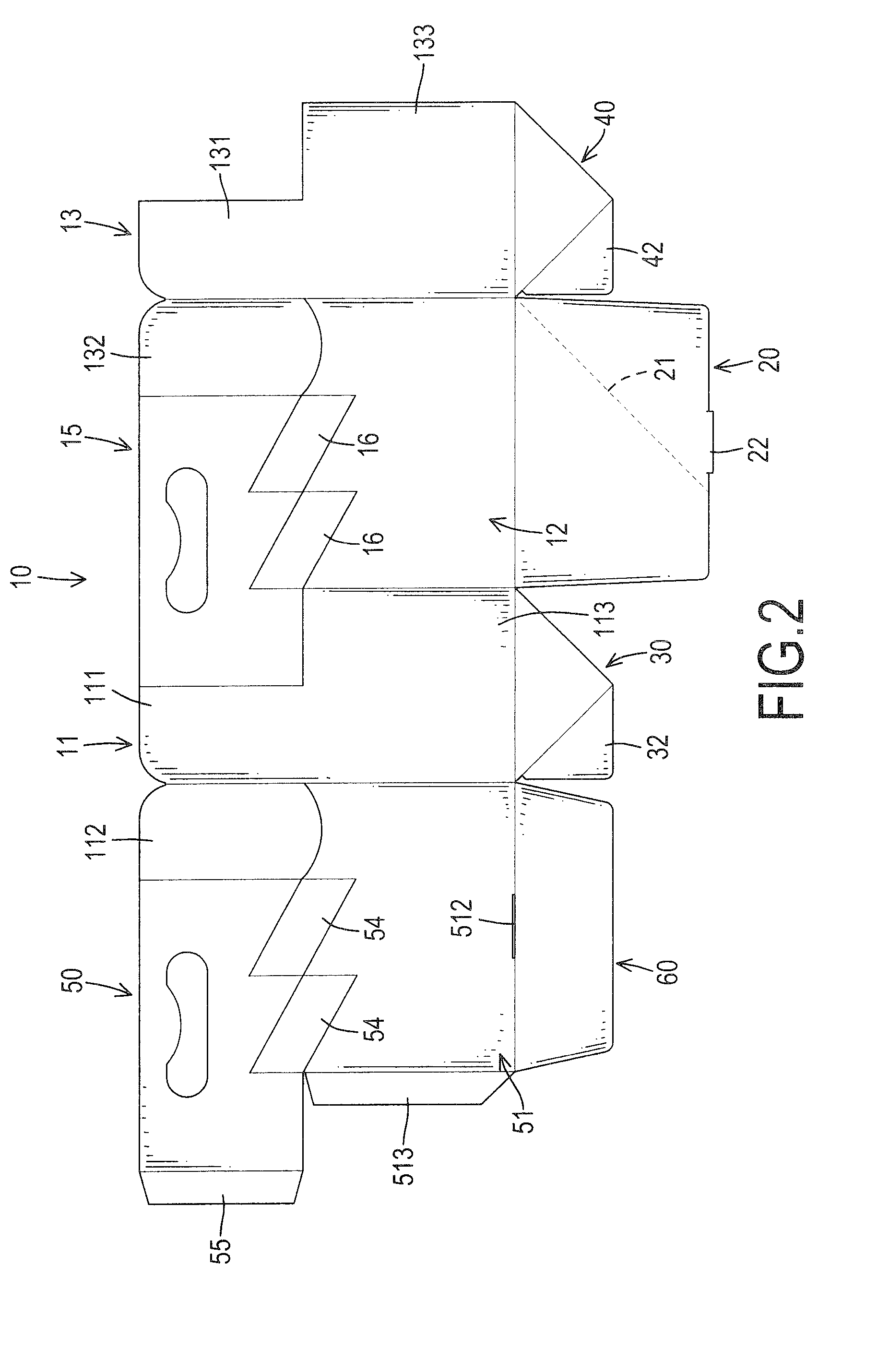

[0019]With reference to FIGS. 1 and 2, a one-piece beverage carton in accordance with the present invention comprises a base (10) having two handle panels (15, 50), two side panels (11, 13), four bottom panels (20, 30, 40, 60), two fascia panels (12, 51) and two attaching tabs (55, 513). The panels (15, 50, 11, 13, 20, 30, 40, 60, 12, 51) may be attached using adhesive, riveting, hot bonding or the like.

[0020]The handle panels (15, 50) abut each other to form a longitudinal partition of the beverage carton.

[0021]The fascia panels (12, 51) and side panels (11, 13) are formed on the handle panels (15,50) and folded to form an exterior of the beverage carton.

[0022]The primary bottom panels (20, 30, 40, 60) abut each other to form a bottom of the beverage carton.

[0023]A chamber is formed between the bottom panels (20, 30, 40, 60), the fascia panels (12,51) and the side panels (11, 13).

[0024]The handle panels (15, 50) are substantially rectangular and each handle panel (15, 50) has a han...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com