Trash can restrict top

a trash can and top technology, applied in the field of trash cans restricting tops, can solve the problems of short product life, inefficient mechanism, and affecting the use of conventional trash cans

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

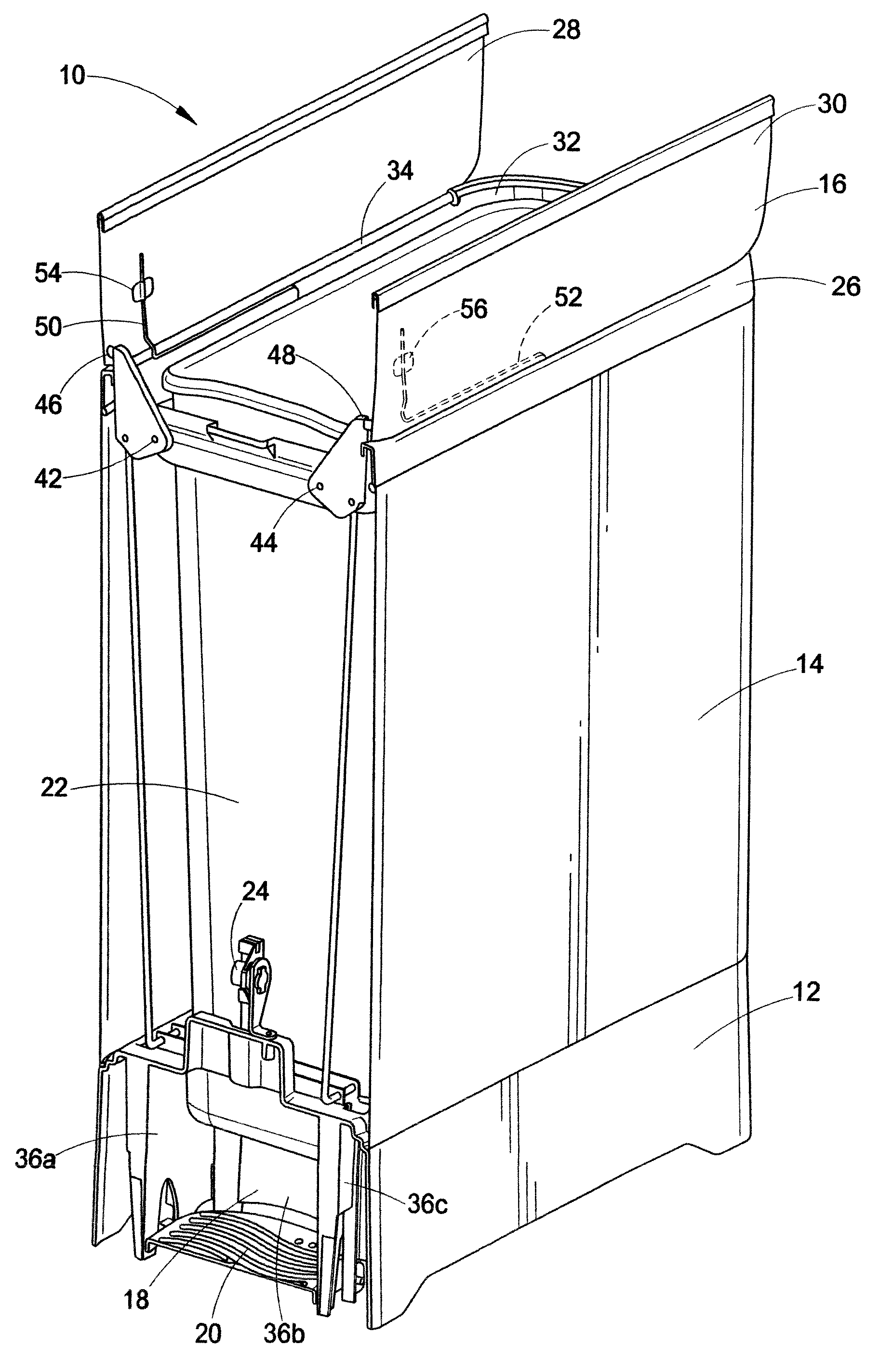

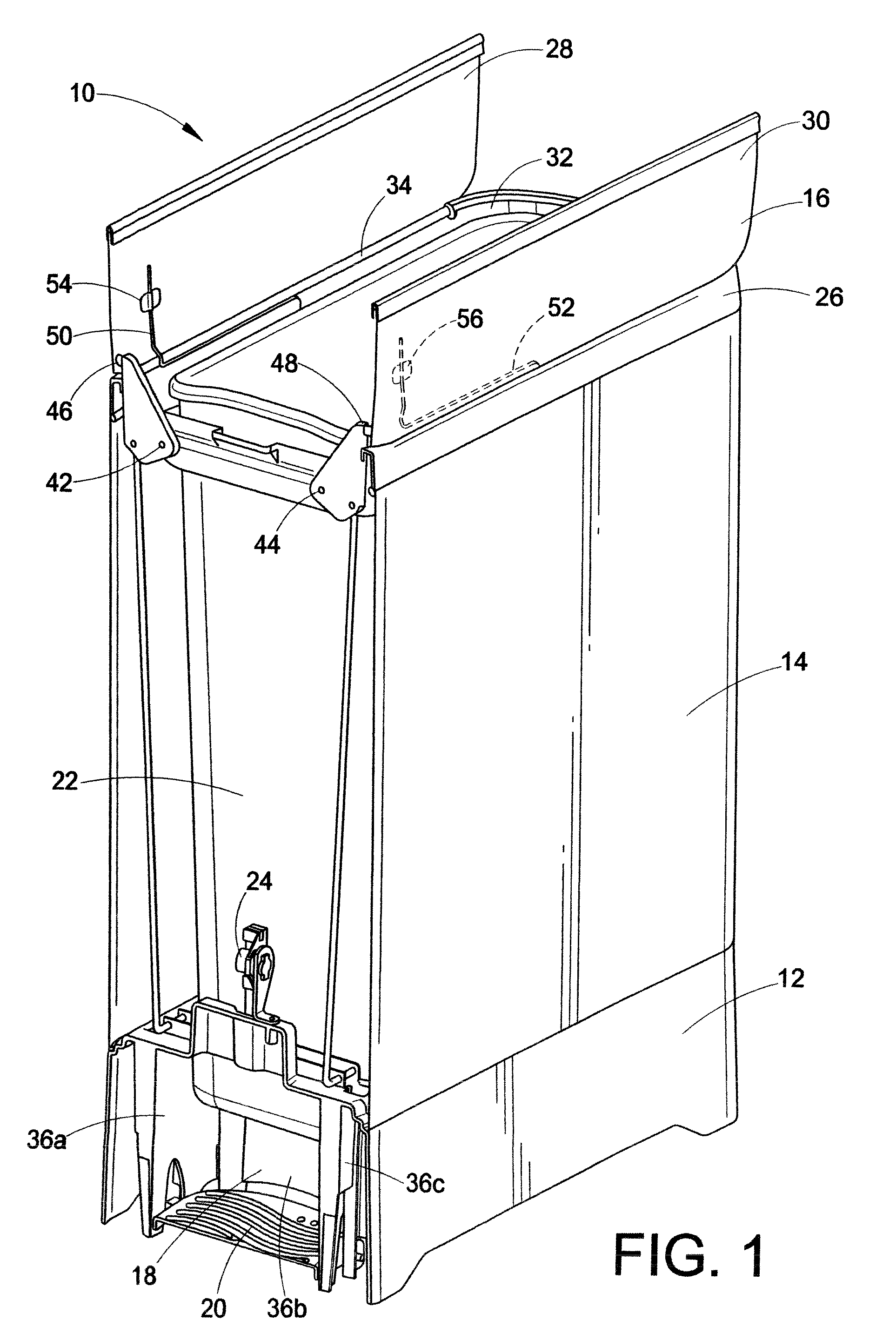

[0013]FIG. 1 illustrates a perspective view of a trash can 10. The front of the trash can 10 is cut away in FIG. 1 to display the mechanism for opening the trash can 10. The trash can 10 comprises a base 12, a body 14 and a top 16 which are permanently fixed together. The base 12 is employed to support the structure of the trash can 10 and to insure that such support is level. The base 12 is comprised of two side walls oriented substantially in parallel to one another, a rear wall and a front. The base 12 is a molded plastic structure. In order to provide greater support, the side walls of the base can be angled (e.g., 5-30 degrees) outward from the top of the side wall such that the base 12 is flared in relation to the body 14 of the trash can 10. Each side of the bottom of the base 12 has a middle portion cut-out to provide access to the bottom of the base for cleaning and maintenance and to allow the trash can to sit on uneven surfaces. The base 12 also includes a rear wall (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com