Bicycle rear suspension system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

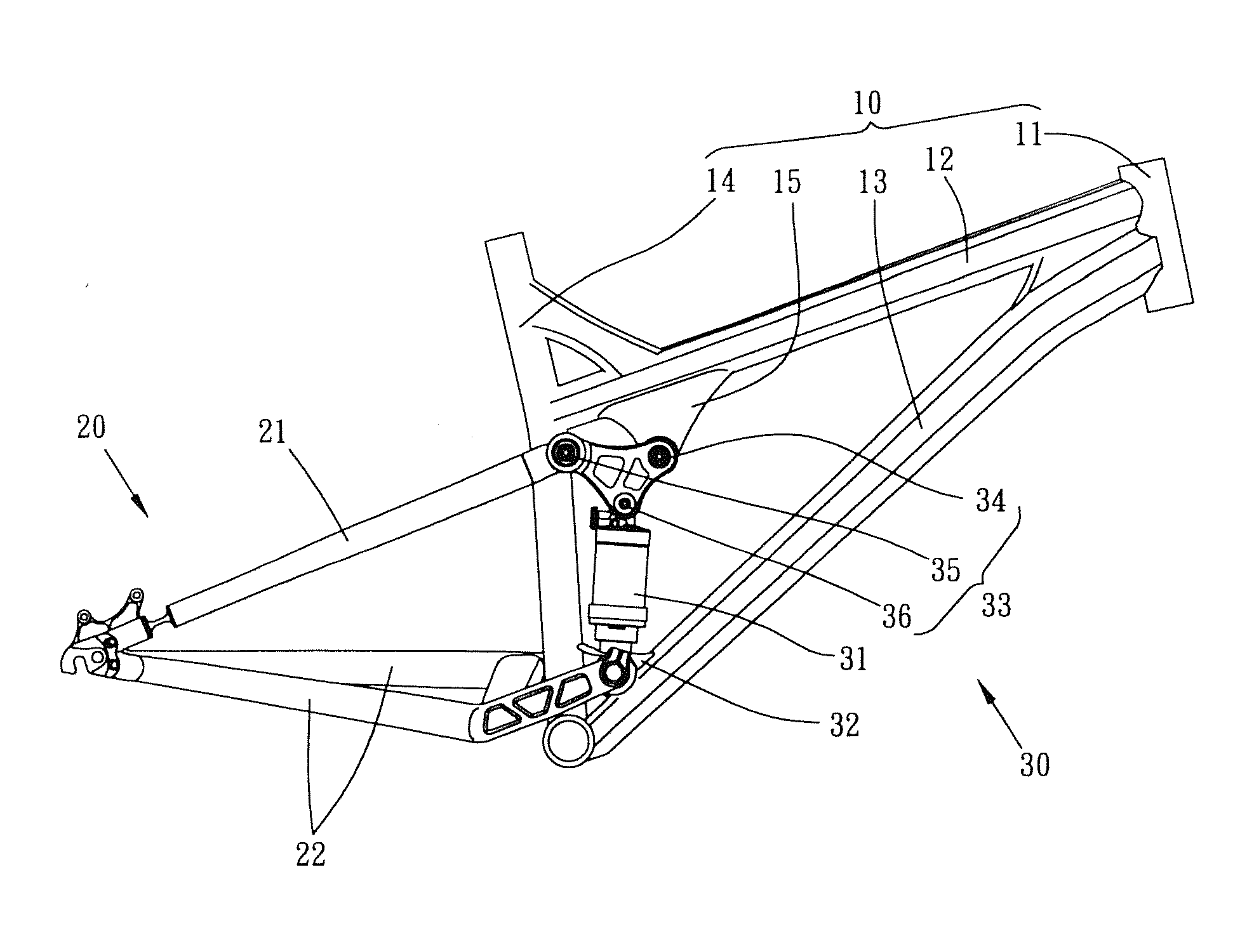

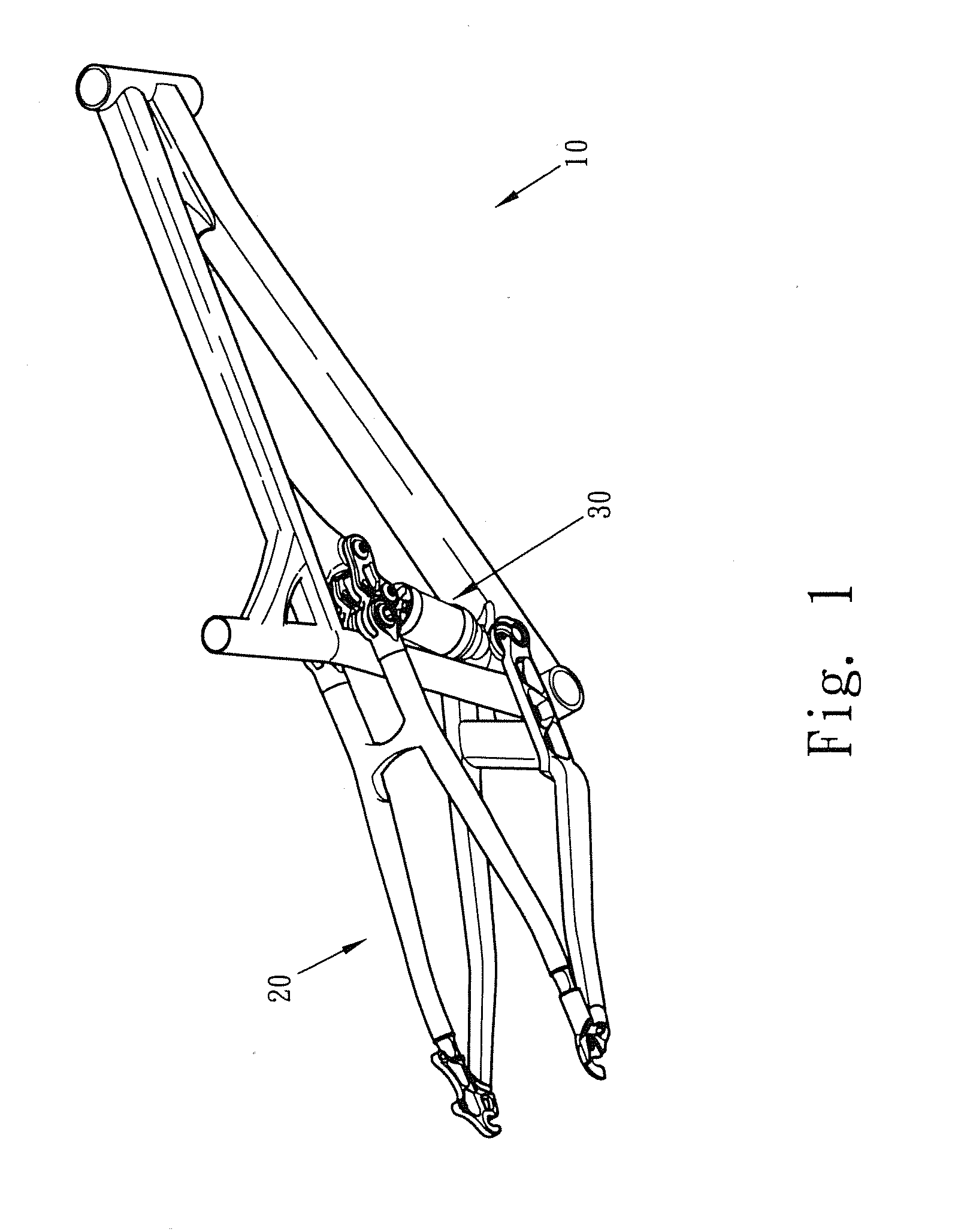

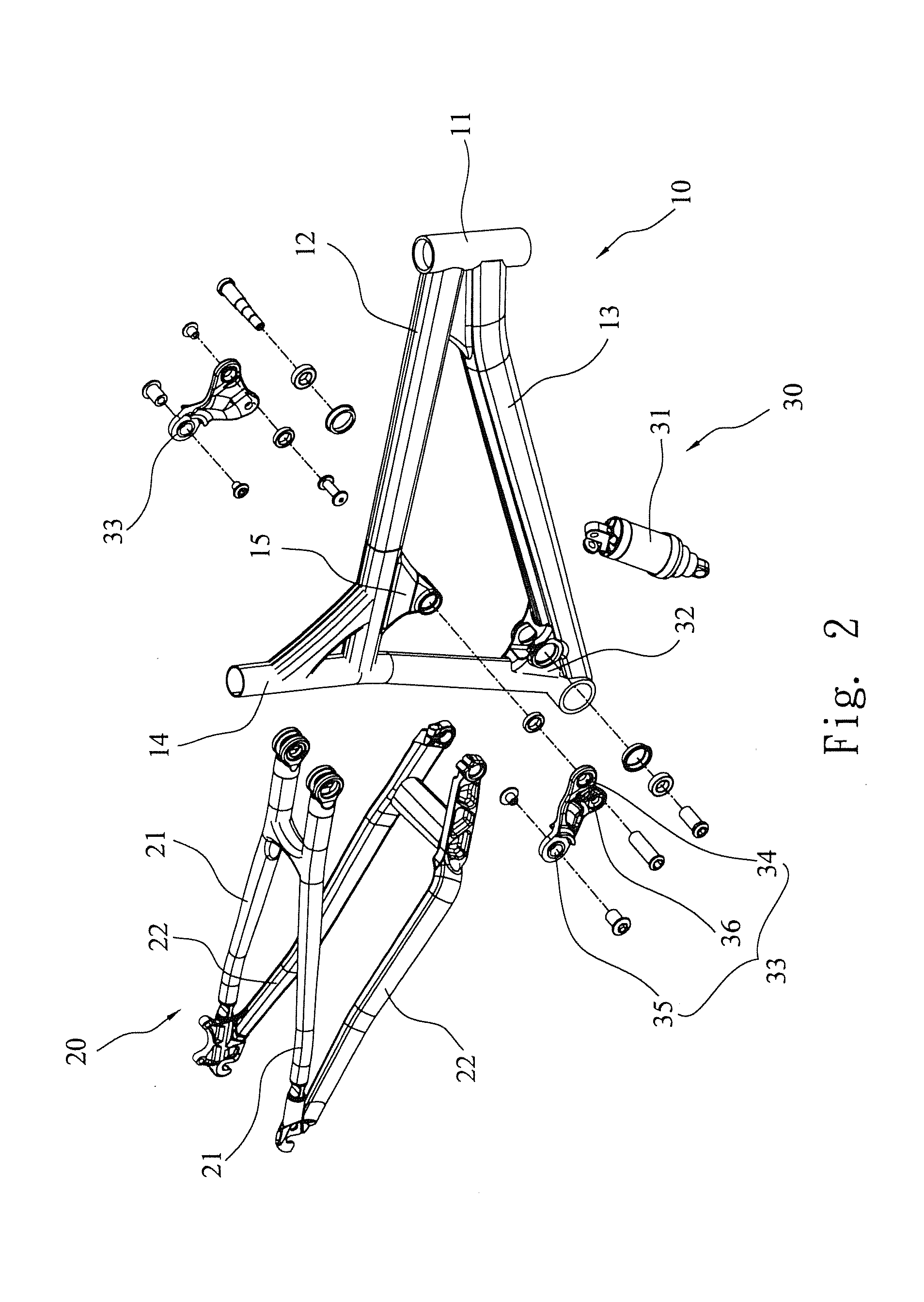

[0028]Referring to FIGS. 1 to 7, a bicycle rear suspension system of the present invention comprises a front part 10, a rear part 20 and a shock absorbing unit 30. The front part 10 includes a top tube 12, a down tube 13 and a head tube 11 which is connected to first ends of the top and down tubes 12, 13. A bottom bracket is connected to a second end of the down tube 13 so as to be connected to a crank which is not shown. A protrusion 15 extends from a lower edge of the front part 10 and a bridge 32 is connected to the bottom bracket and the down tube 13.

[0029]The rear part 20 includes two seat stays 21 and two chain stays 22 which have two dropouts on first ends thereof so as to be connected with an axle of the rear wheel (not shown). The seat stays 21 have first ends pivotally connected to the dropouts and two second ends of the two seat stays 21 are pivotally connected to a first end of a connection member 33 at a first pivot point 35. The connection member 33 is composed of two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com