Housing structure

a technology of housing structure and housing plate, applied in the field of housing plate, can solve the problems of insufficient stability and insufficient self-supporting of the housing plate alone, and achieve the effect of simple and reproducible connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

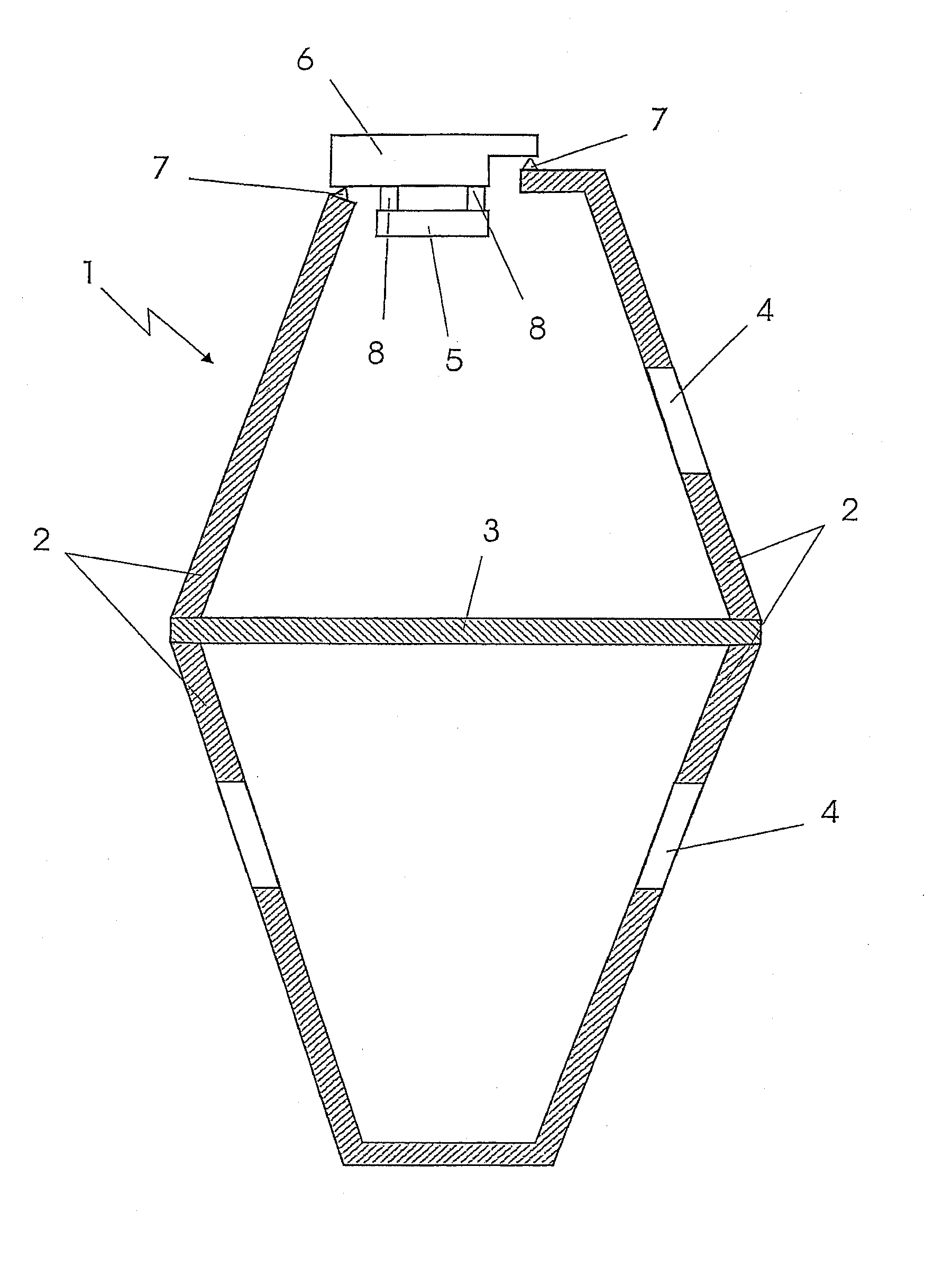

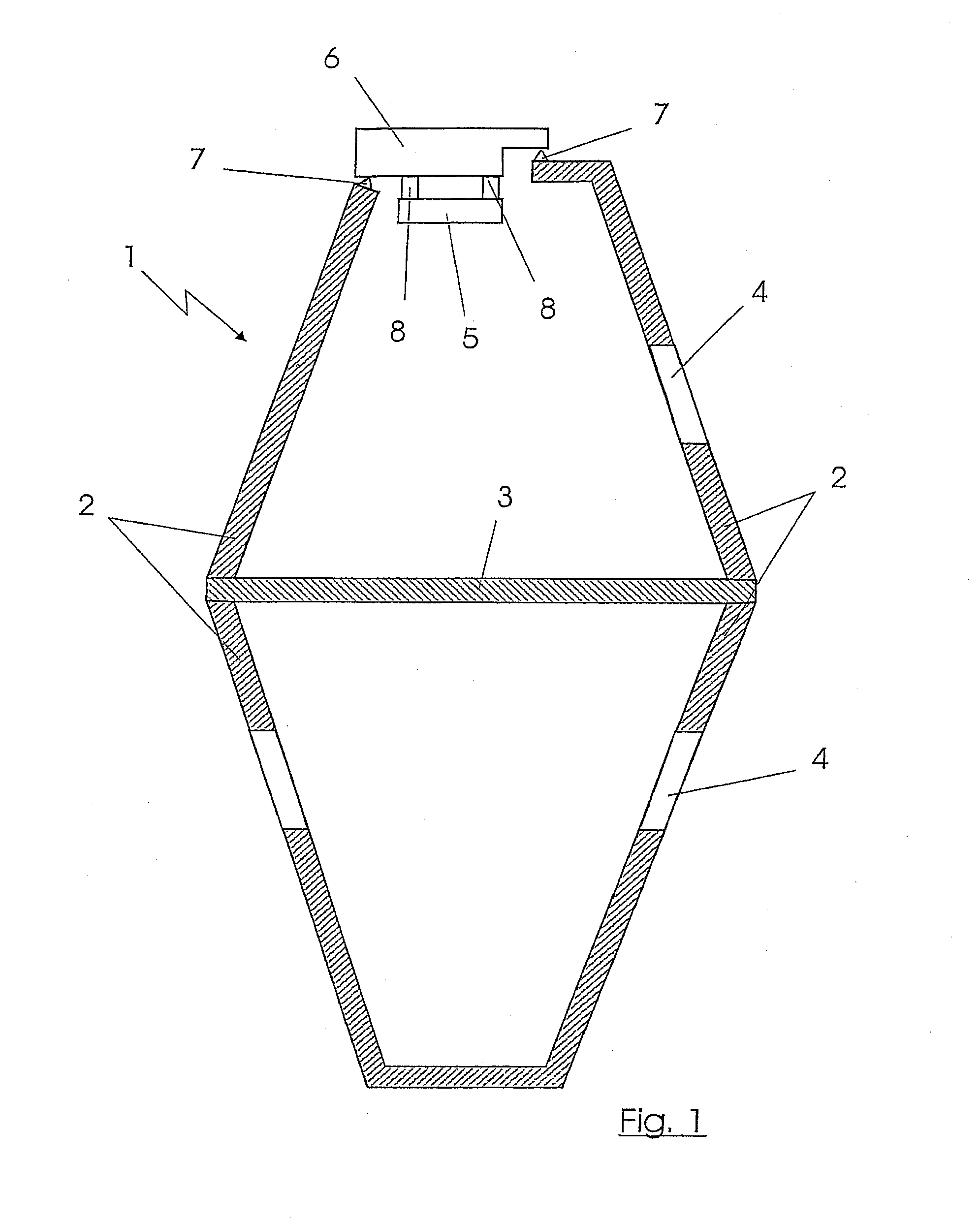

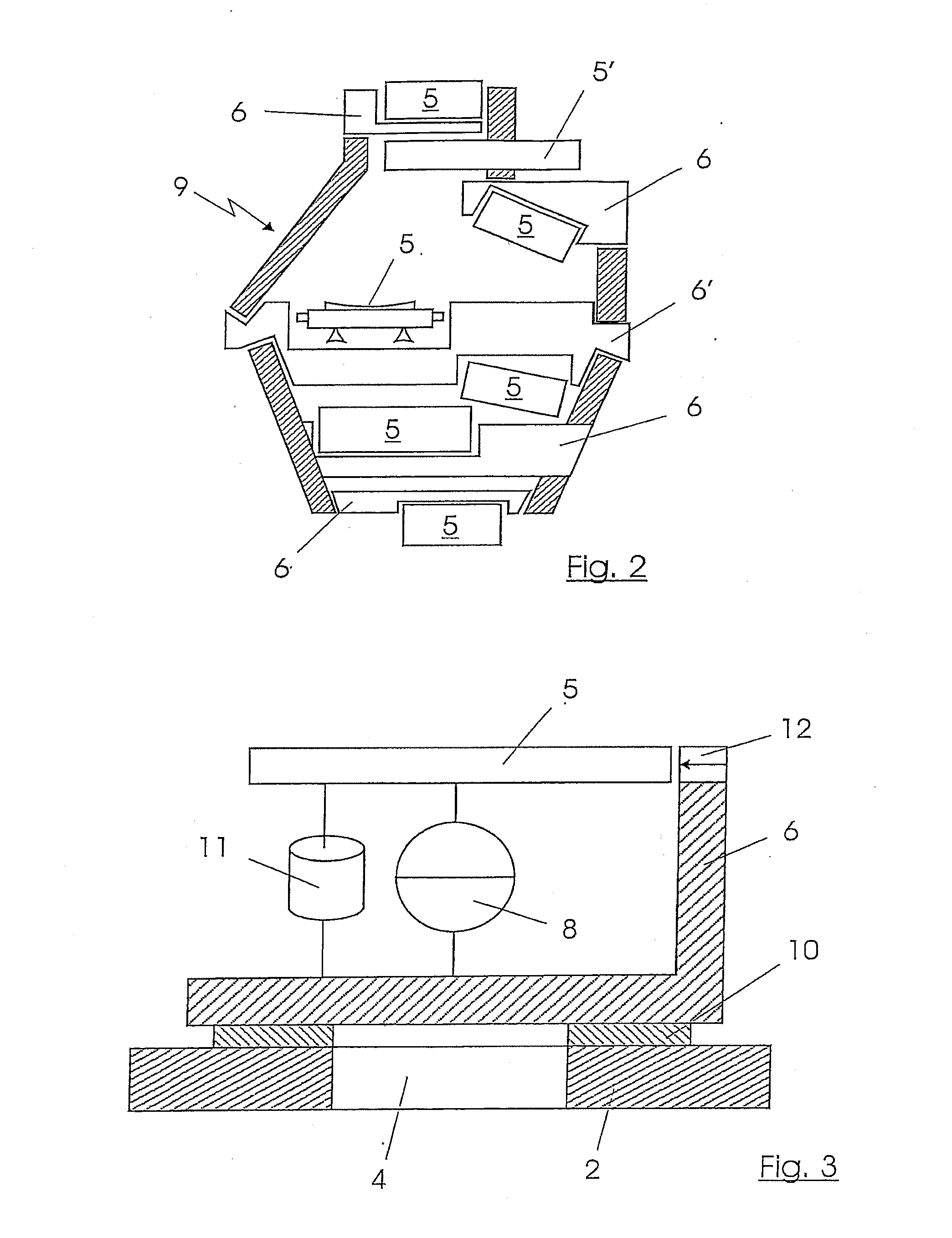

[0016]The housing structure illustrated in FIGS. 1 and 2 has a frame structure 1 which is assembled from several frame parts 2 and reinforcing plates 3. The frame structure 1 is provided with a multiplicity of cutouts or openings 4. Optical elements 5 with their mounts 6 are inserted into the openings 4. Connecting elements 7 (not illustrated in more detail) are provided for this purpose. Setting members or actuators 8 are arranged between the mount 6, which can be constructed as a base element, and the optical element 5, for example, a mirror 5. The arrangement and configuration of the setting members 8 are not described in more detail below, since they are known in principle. The setting members 8 should as far as possible permit adjustments of the optical element 5 in six degrees of freedom, and can be constructed for this purpose as hexapods, for example.

[0017]FIG. 2 shows a housing structure which can be, for example, an objective housing 9 of a projection objective in microlit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degrees of freedom | aaaaa | aaaaa |

| coefficient of thermal expansion | aaaaa | aaaaa |

| degrees of freedom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com