Candle Wick

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

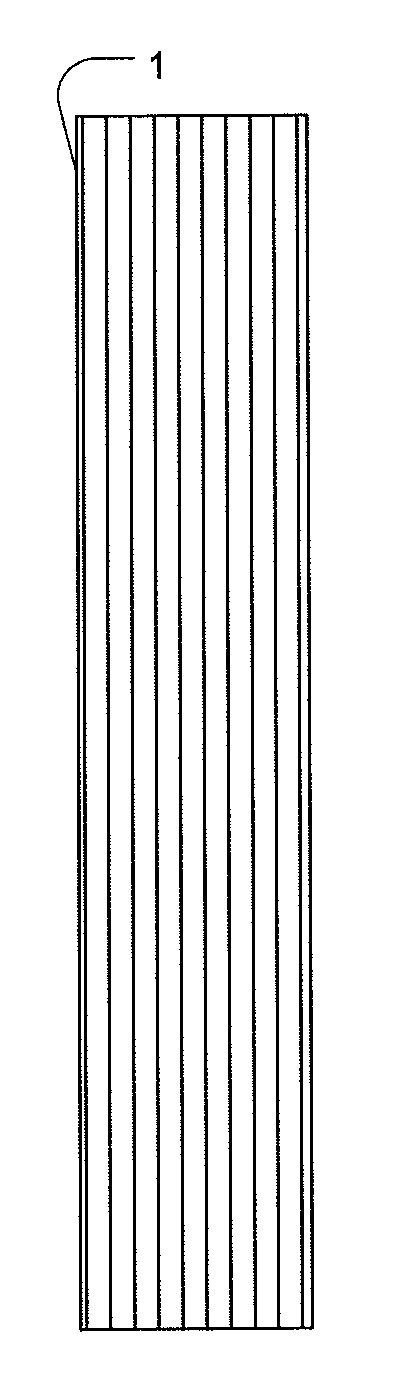

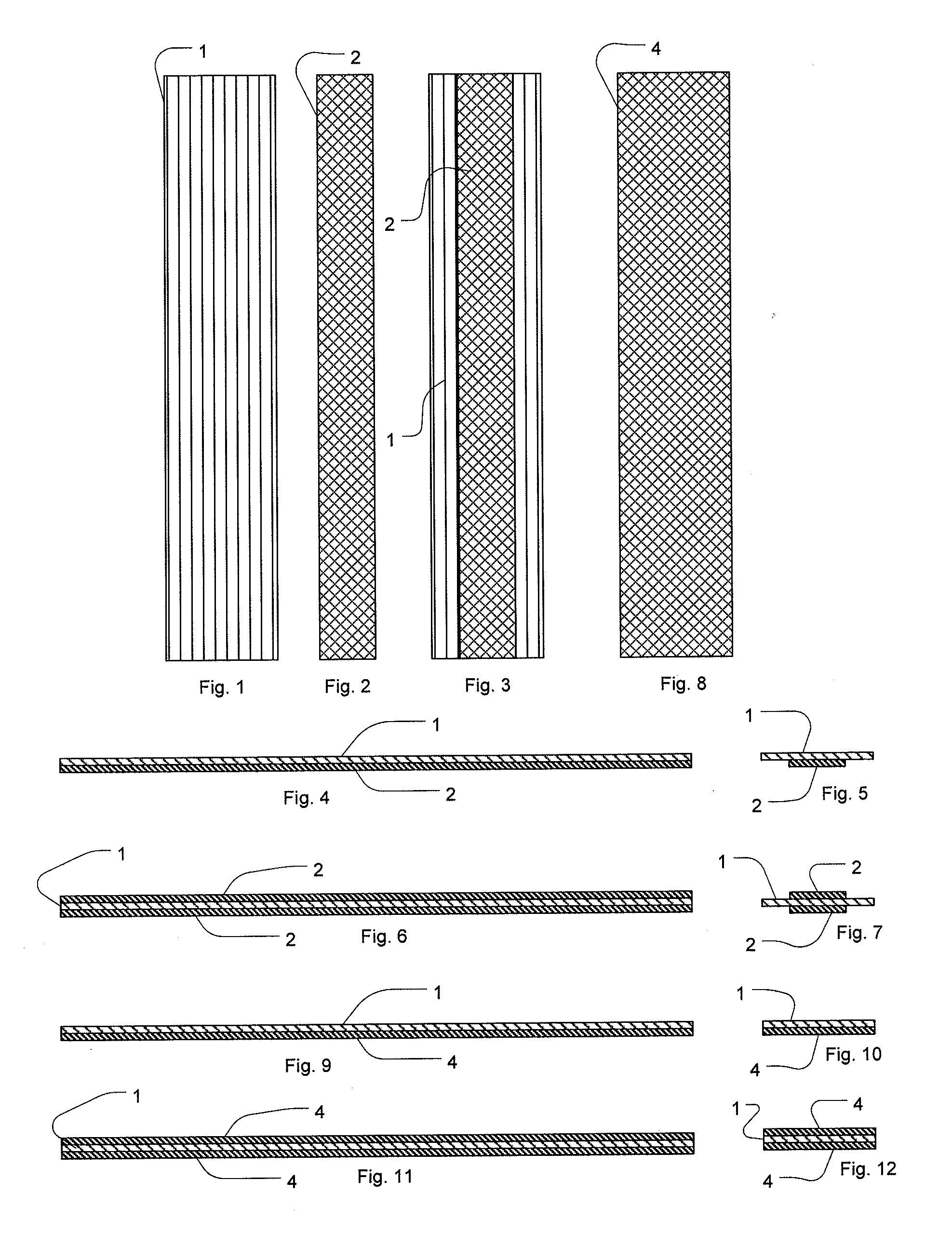

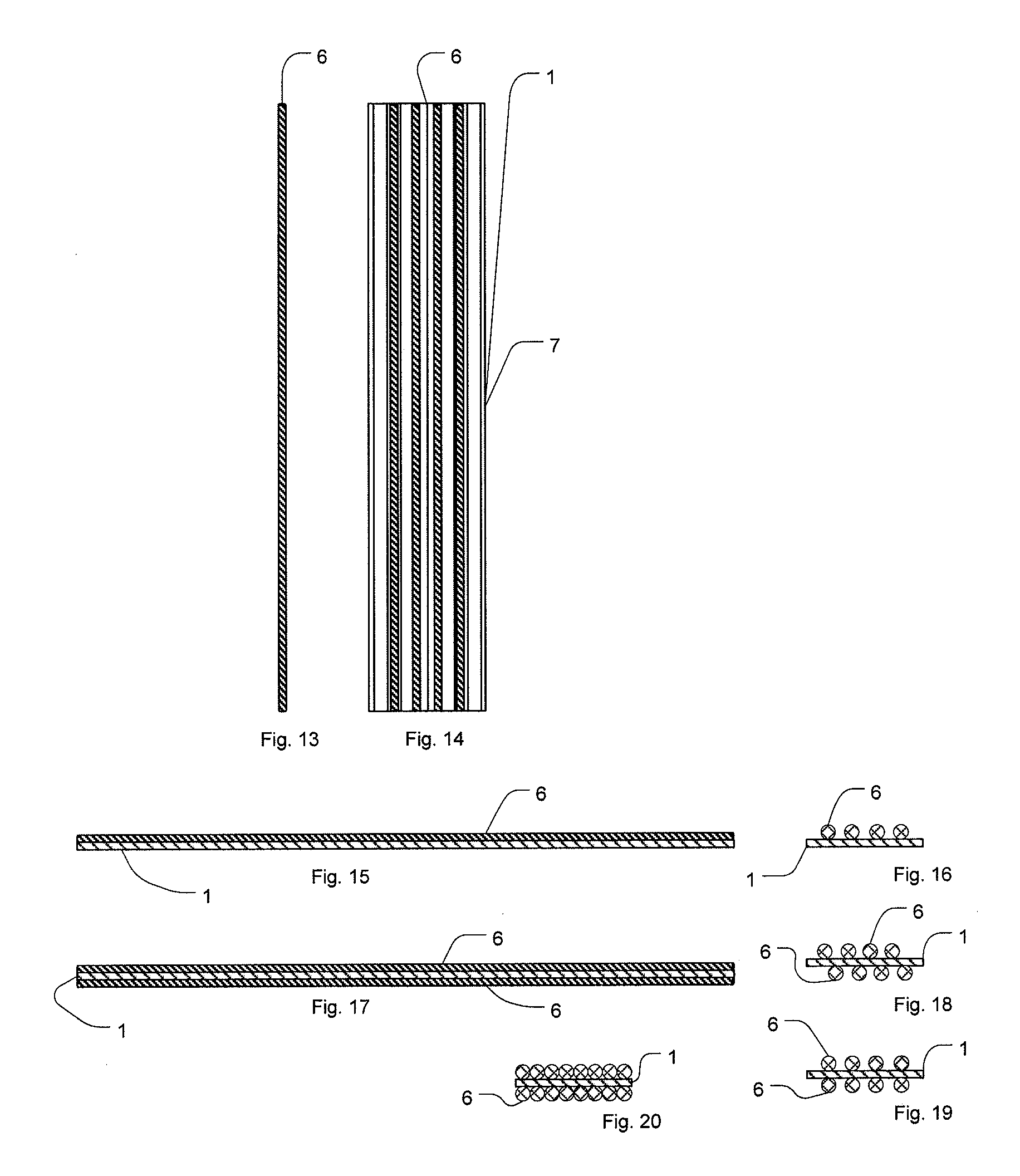

[0039]Referring to FIGS. 1-5, the wick of the present invention includes a rigid planar wick 1 and a planar fabric wick 2. Fabric wick 2 is adhered to rigid wick 1 to form a unified wick 3 as shown in FIG. 3.

[0040]The rigid wick 1 is formed in a planar shape that can be produced from a number of hard and soft woods. In preferred embodiments cherry is used. The rigid wick 1 has a thickness between 0.015 inch and 0.04 inch. The fabric wick 2 has a thickness of between 0.025 inches and 0.065 inches. The length of the rigid wick 1 and fabric wick 2 would generally be the same, and the actual length will depend upon the height of the candle in which the wick is used. In the embodiment shown in FIGS. 1-5, the fabric wick 2 has a shorter width than the rigid wick 1 as shown in FIG. 3, and the relative dimensions depend in large part on the vessel diameter for the candle.

[0041]In the alternate embodiment shown in FIGS. 6 and 7, a second planar fabric wick 2 is adhered to the rigid wick 1 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com