Vibration-absorbing air sheath having improved end-closing structure

a technology of air sheath and end-closing structure, which is applied in the field of packaging materials, can solve the problems of air column bursting, entire buffer structure losing the vibration-absorbing function, and prior art defects, and achieve the effect of maximizing the buffering area and corresponding width of the accommodating spa

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]For achieving the foregoing objectives and features, one preferred embodiment is herein described with reference the accompanying drawings for people having ordinary skill in the art to better implement the present invention.

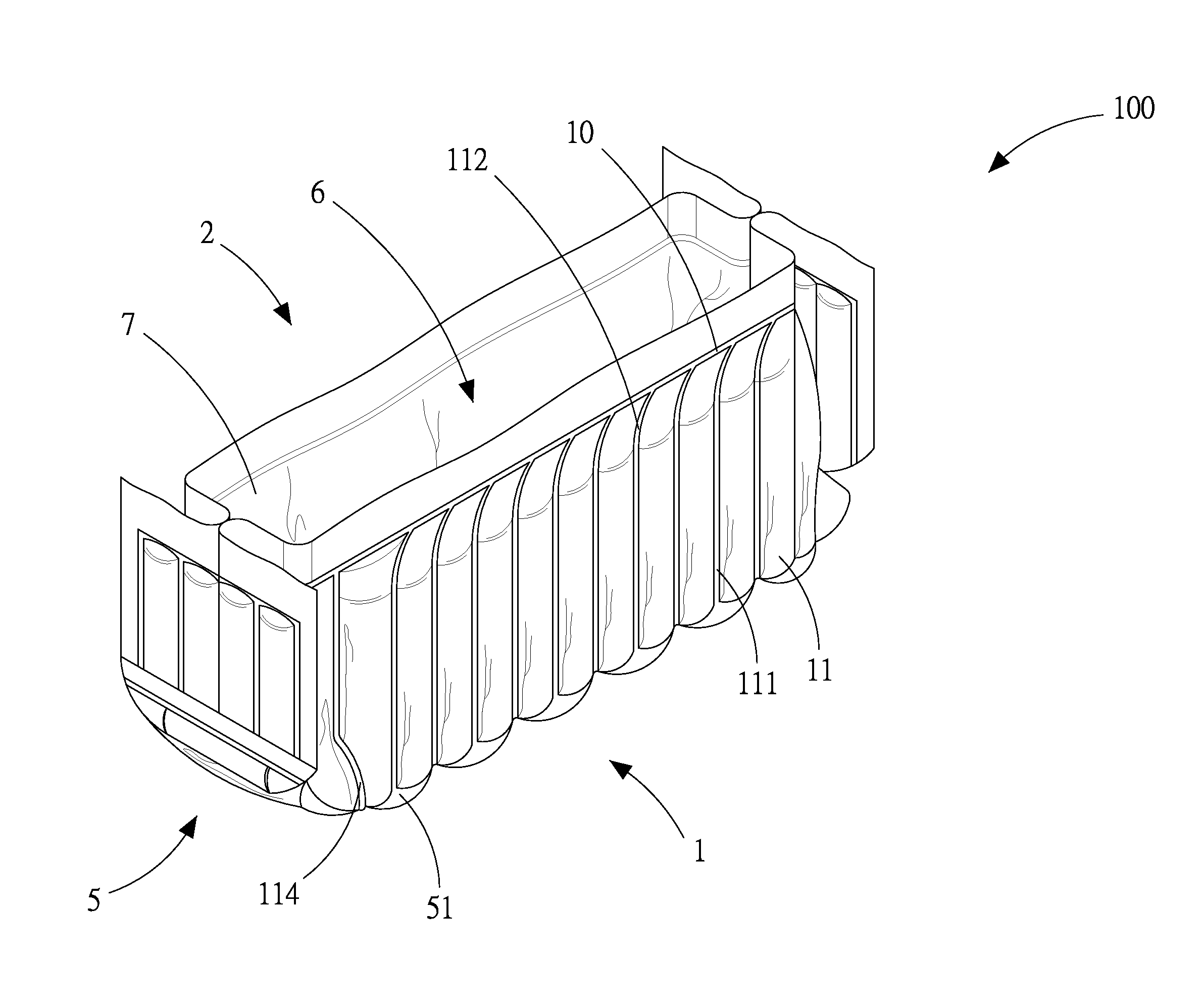

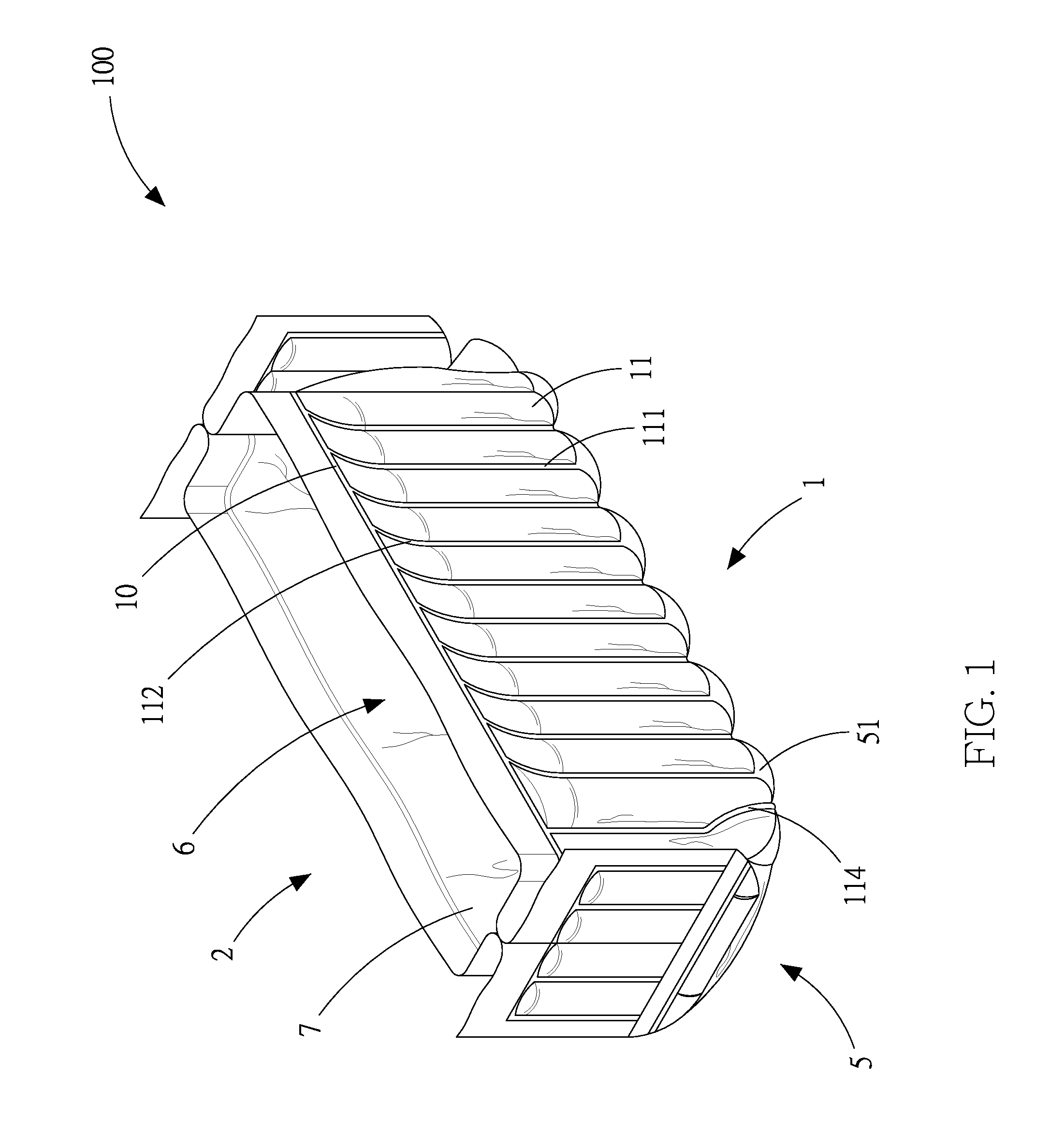

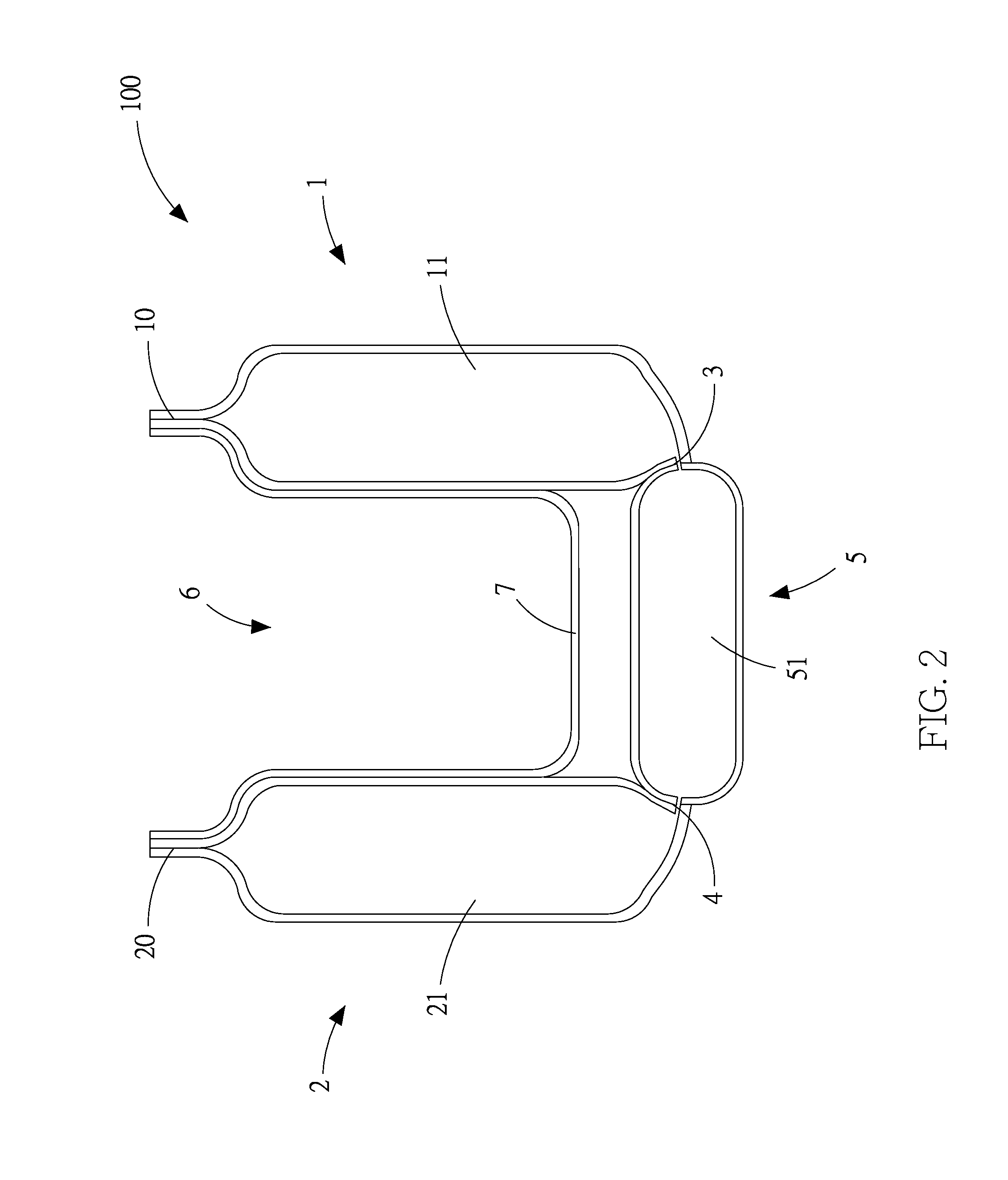

[0030]Referring to FIG. 1 through FIG. 4, FIG. 9, FIG. 10 and FIG. 17 for a perspective view of one preferred embodiment of the present invention, a cross-sectional view of an accommodating space the preferred embodiment of the present invention, a cross-sectional view of a binding portion of the preferred embodiment of the present invention, a cross-sectional view of adjacent air columns inside the binding portion the preferred embodiment of the present invention, an exploded view of the preferred embodiment of the present invention, an expanded view of the first, second and third buffering walls according to the preferred embodiment of the present invention and an applied view of the preferred embodiment of the present invention. As shown, the disclosed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com