Atomizing head, atomizer and electronic cigarette having same

a technology of atomizer and electronic cigarette, which is applied in the field of electronic cigarettes, can solve the problems of tobacco liquid leaking from the liquid blocking element, and achieve the effect of preventing the leakage of tobacco liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

##s embodiment

FIRS EMBODIMENT

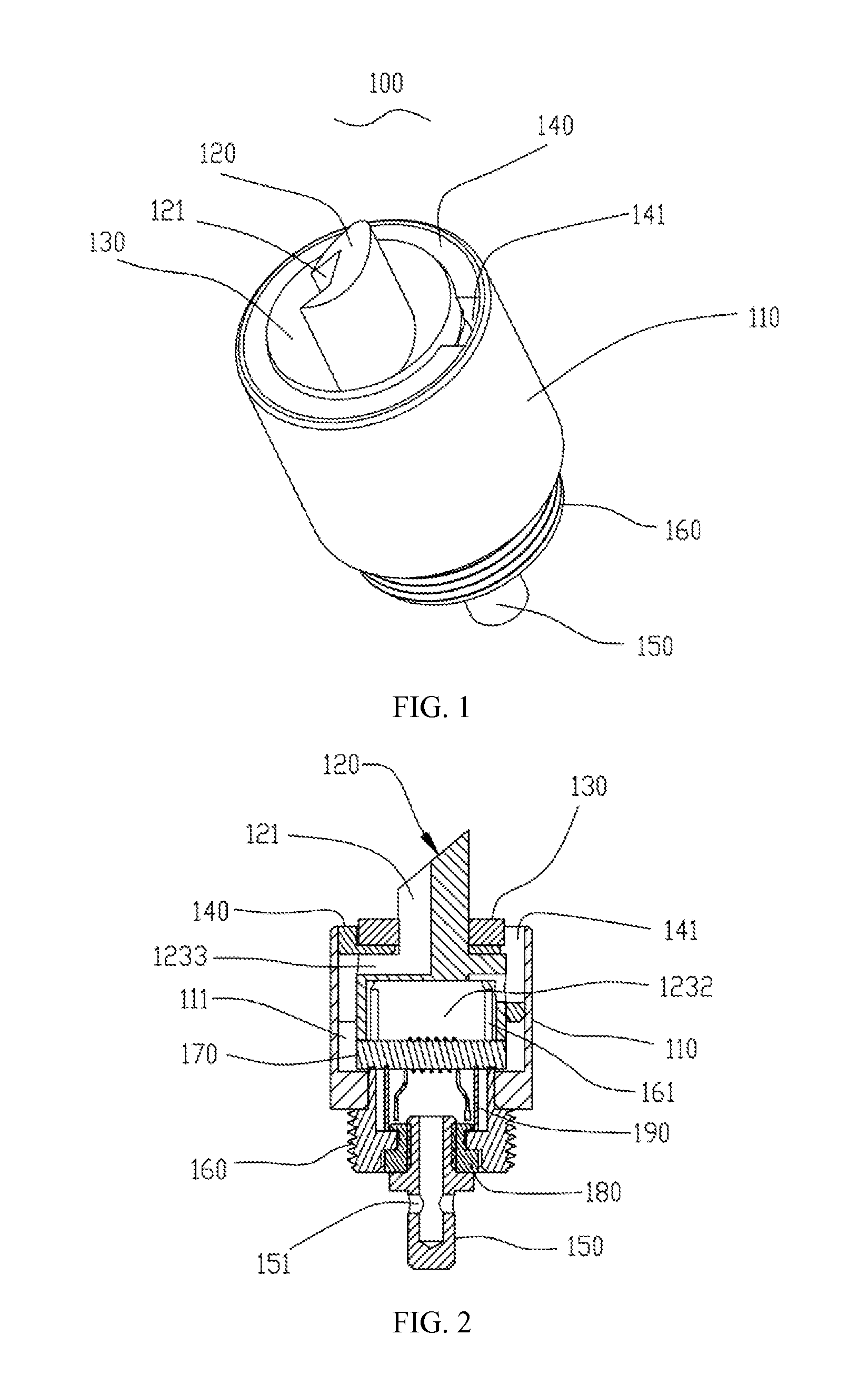

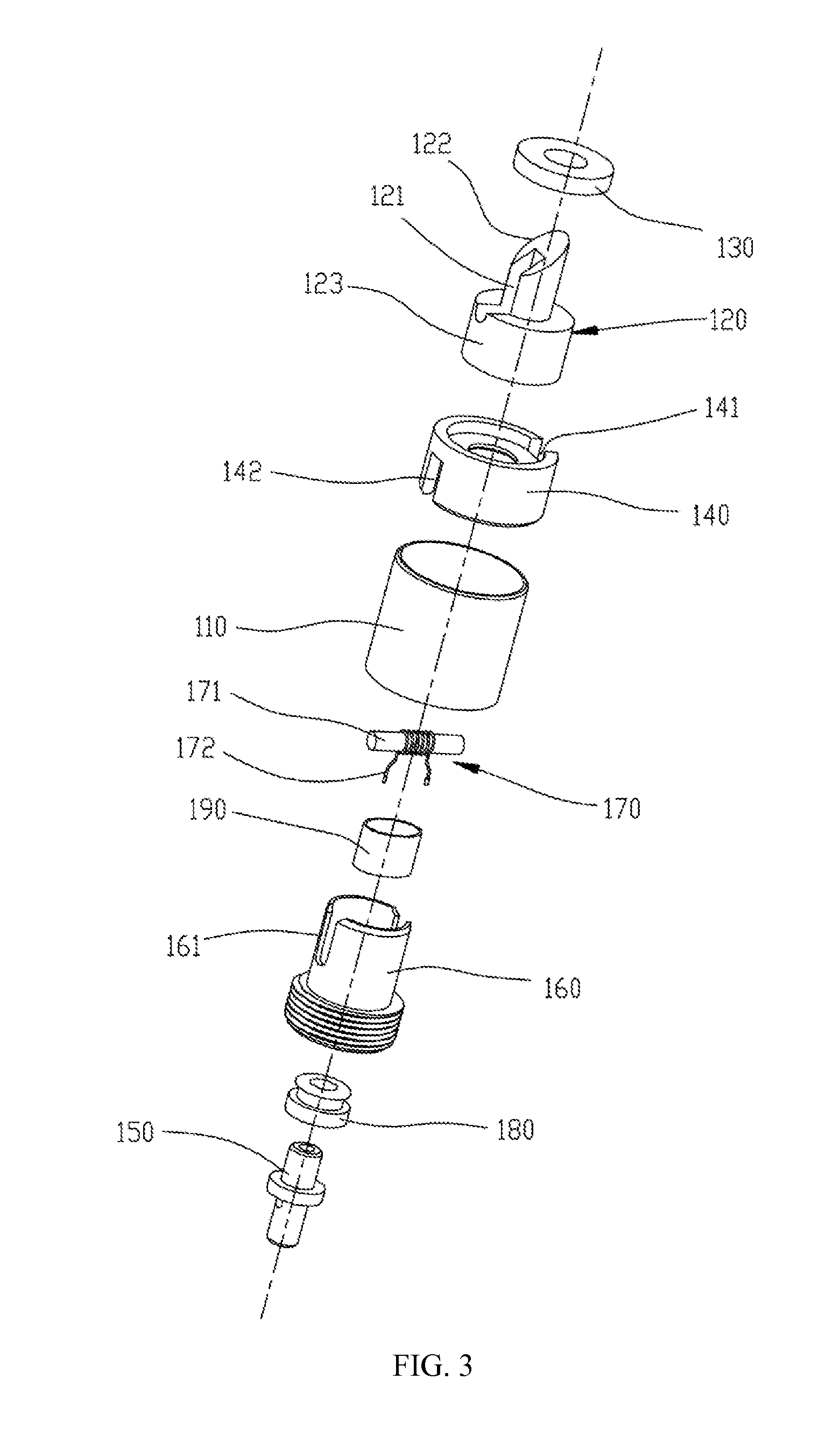

[0032]Referring to FIGS. 1-2, an atomizing head 100 for an electronic cigarette is shown. The atomizing head 100 includes a holder 110, an air inlet 151, an air outlet 141, a piercing element 120, a first electrode 160, a second electrode 150, a buffer chamber 111, an atomizing cavity 1232, and an atomizing component 170. The piercing element 120 is configured for pricking a liquid supply. The atomizing component 170 is configured (i.e., structured and arranged) for absorbing heating tobacco liquid in the buffer chamber 111 and heating the tobacco liquid. Both of the air outlet 141 and the air inlet 151 are in communication with the atomizing cavity 1232. The air inlet 151 is defined in the second electrode 150. The first electrode 160 and the second electrode 150 are configured for connecting to an external power supply. An insulating body 180 is sandwiched between the first electrode 160 and the second electrode 150. The piercing element 120 includes a liquid inlet ...

second embodiment

[0041]Referring to FIGS. 7-8, an atomizing head 300 according to a second embodiment is shown. The atomizing head 300 includes a holder 310, an air inlet 351, an air outlet 331, a piercing element 320, a first electrode 360, a second electrode 350, a buffer chamber 311, an atomizing cavity 3232, and an atomizing component 370. The air outlet 331 and the air inlet 351 are all in communication with the atomizing cavity 3232. The air inlet 351 is defined in the second electrode 350. An insulating body 380 is arranged between the first and the second electrodes 350, 360. The piercing element 320 defines a liquid inlet 321. As shown in FIGS. 8 and 11, the air outlet 331 and the liquid inlet 3321 are arranged on one side of the atomizing head 300.

[0042]Referring to FIGS. 9-10, the piercing element 320 includes a connecting part 323 and a piercing part 322. The liquid inlet 321 is defined in the piercing part 322. The connecting part 323 defines an air hole 3231 in a top surface. The air h...

third embodiment

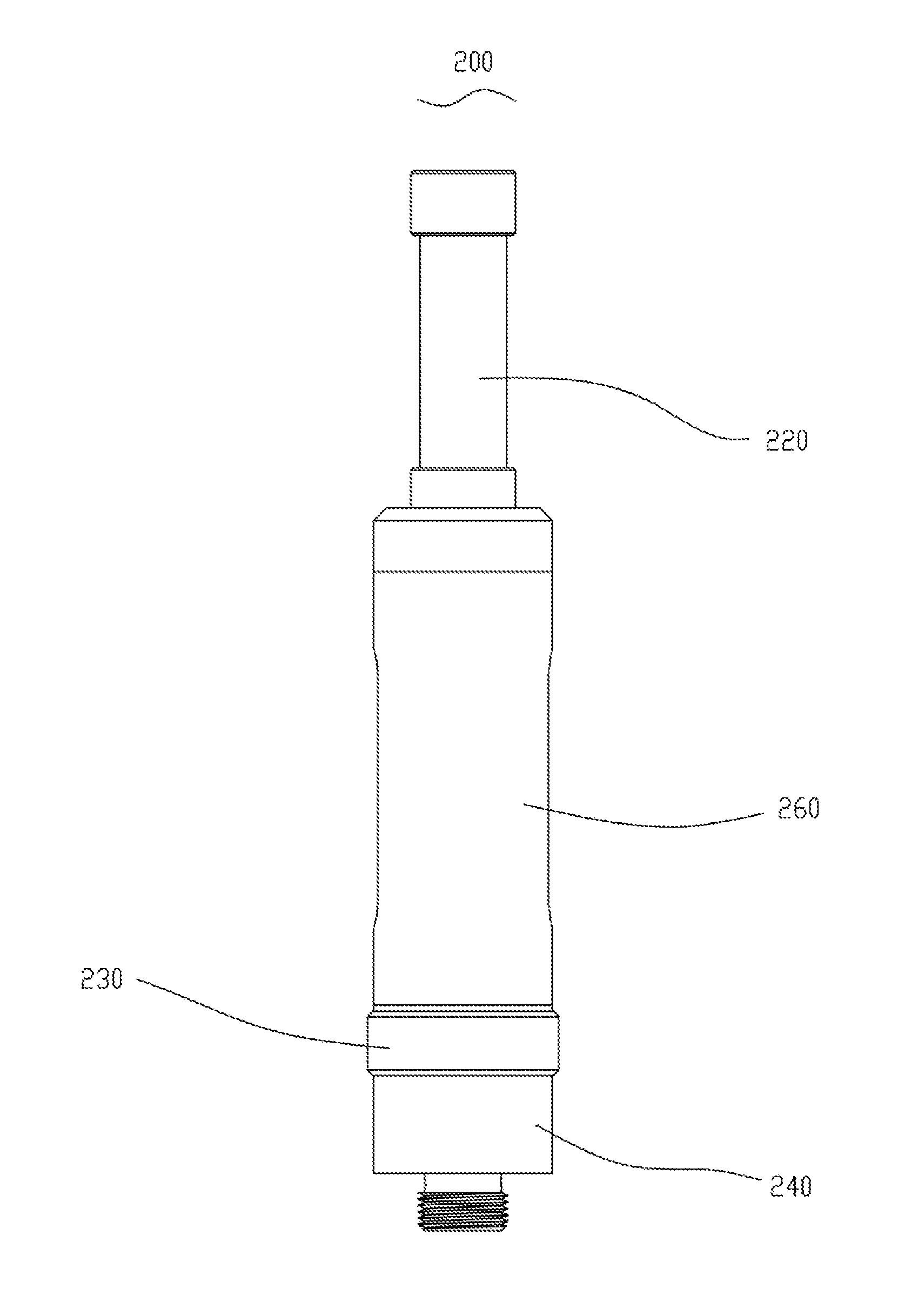

[0046]Referring to FIGS. 14-15, an atomizer 200 for an electronic cigarette is shown. The atomizer 200 includes an atomizing head 100 according to the first embodiment, an atomizing tube 210, a mouthpiece 220, a connector 230, and a threaded electrode 240. The mouthpiece 220 and the connector 230 are arranged at two opposite ends of the atomizing tube 210. The threaded electrode 240 is adapted for connecting with an external power supply. The atomizing tube 210 defines an accommodating space for receiving a liquid supply. In the present embodiment, the liquid supply is a liquid cup 270 made of transparent material.

[0047]Referring to FIG. 16, the atomizing head 100 is detachably engaged in the connector 230.

[0048]Referring to FIGS. 16-18, the connector 230 includes a plurality of first screw threads 231, and a plurality of second screw threads 231. The threaded electrode 240 includes a plurality of third screw threads 241, a plurality of fourth screw threads 242, and a plurality of f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com