Brackets for Temporary Support of a Rail Between Upright Posts During Construction of a Fence or the Like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

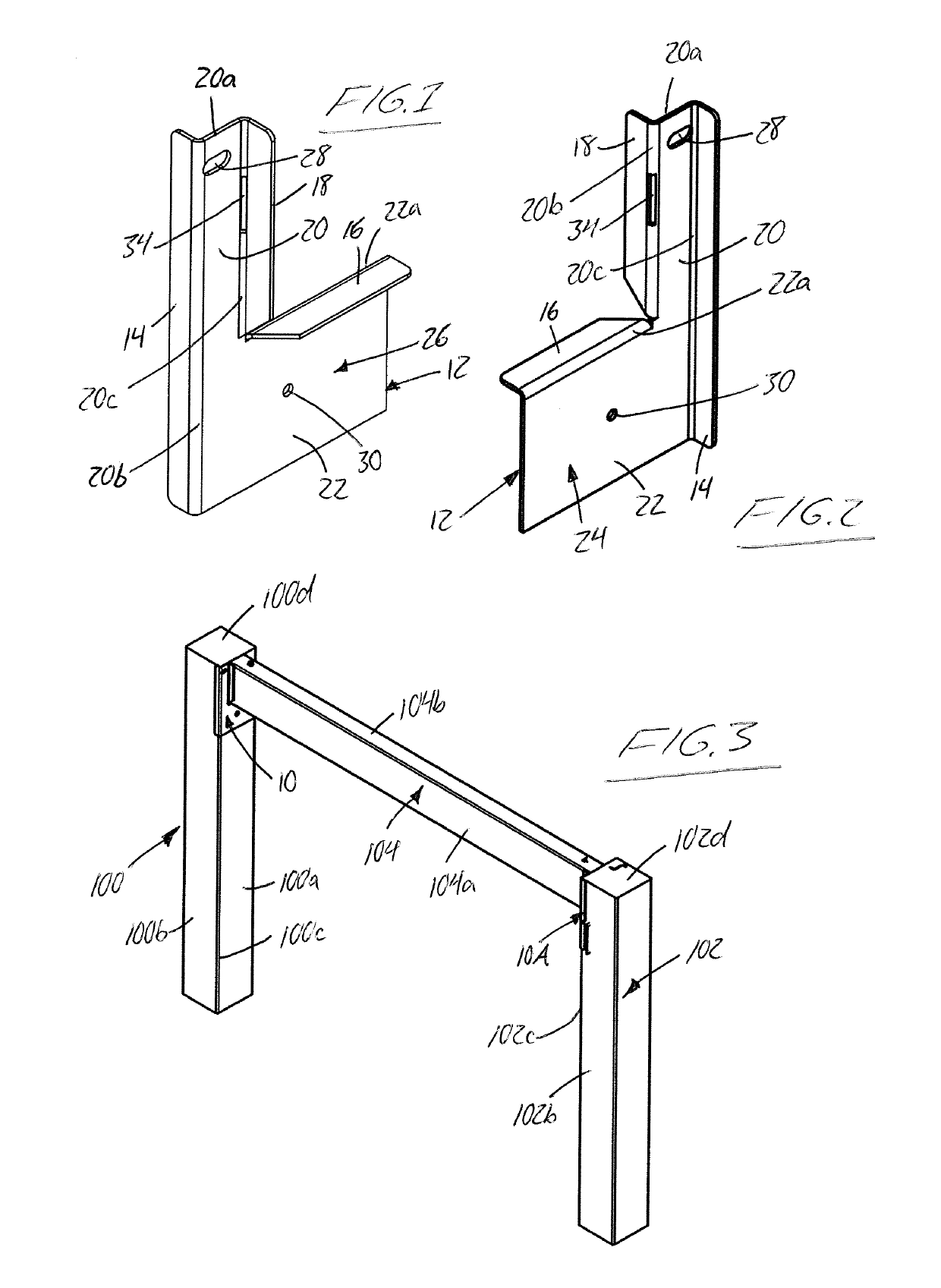

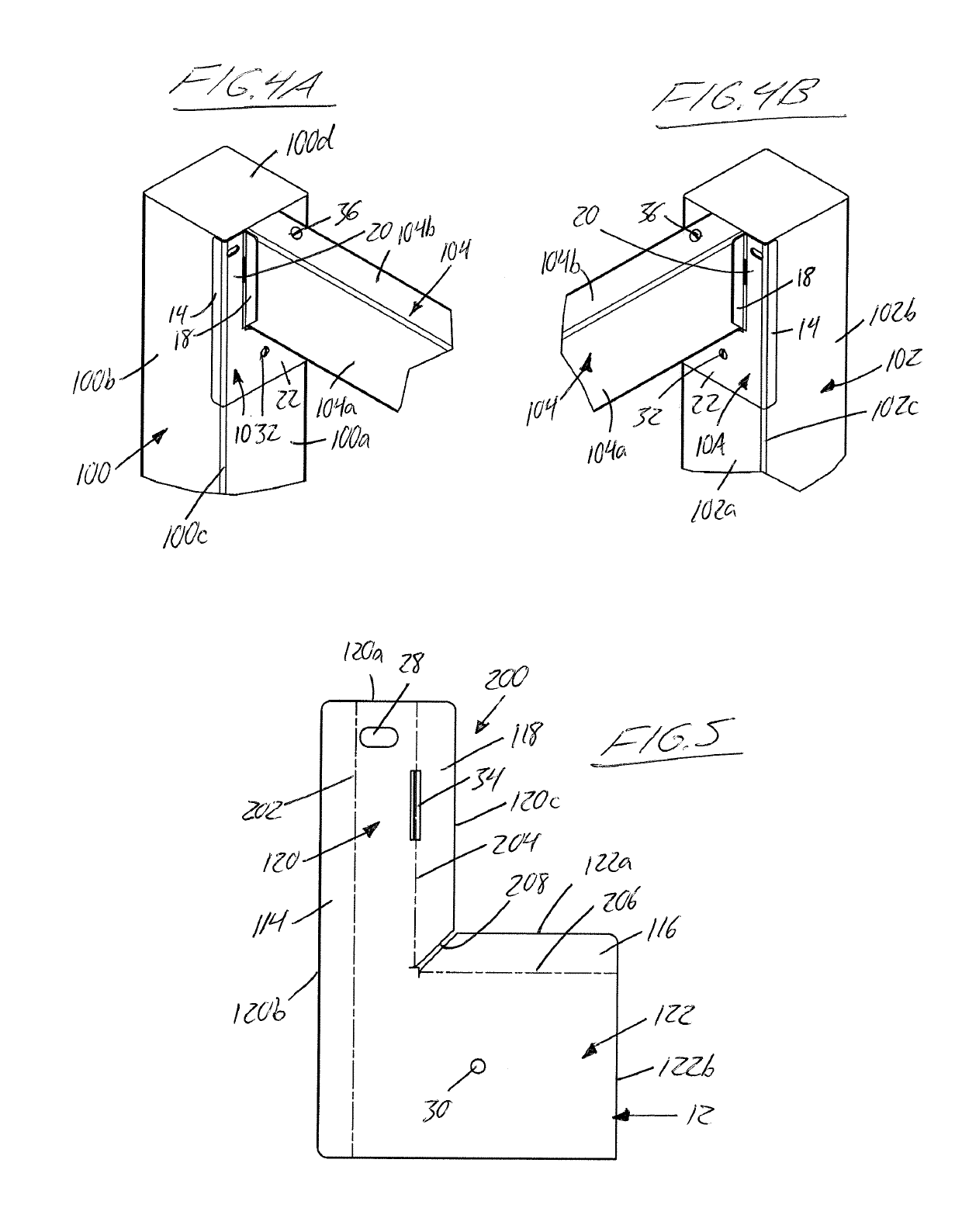

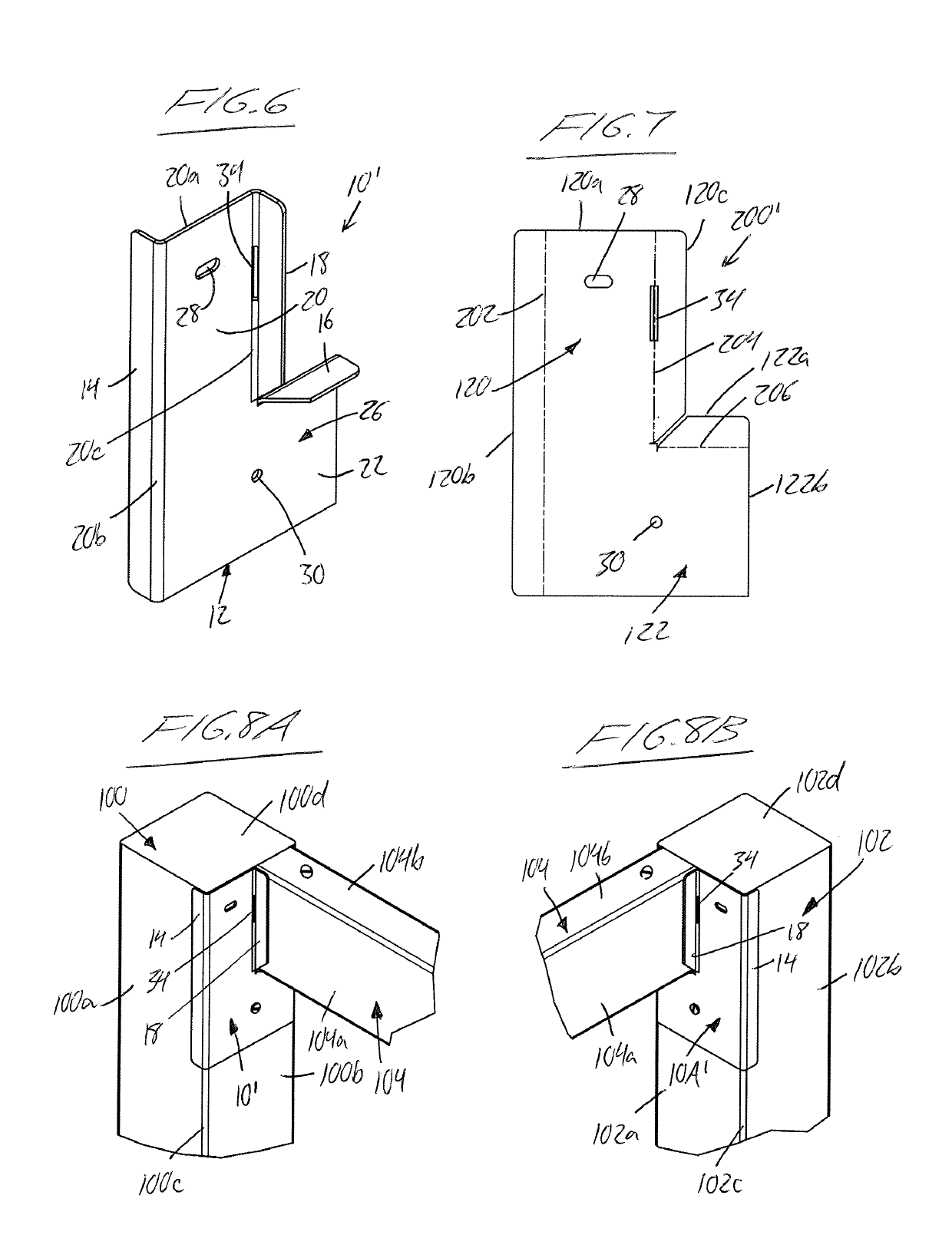

[0068]FIG. 1 illustrates one bracket 10 of a two-bracket rail support system according to the present invention. The bracket 10 is shown from opposing sides in FIGS. 1 and 2, and is referred to herein as the left bracket intended for use together with a cooperating right bracket of mirrored configuration to the left bracket. Each bracket is intended to temporarily support a respective end of a fence rail on a respective one of two neighbouring fence posts during construction of a fence, as shown in FIG. 3. Each fence post 100, 102 stands vertically upright from an area of ground beneath which the bottom end of the fence post is buried to anchor it in this upright position. Each fence post has a square cross-sectional shape in horizontal cross-sectional planes that lie perpendicularly to the central vertical axis of the fence post. Once installed, the rail 104 spans horizontally between the two vertical posts 100, 102 in elevated relation above the ground in an in-line position betwe...

third embodiment

[0088]To allow optional use of differently sized rails, and more particularly rails of different edge-to-edge face width (which corresponds to the height of the rail in its installed face-out edge-up orientation), the shoulder of each third embodiment bracket 10″, 10A″ features two shoulder flanges 18A, 18B instead of a single shoulder flange spanning the full height from the seating flange 16 to the top end 20a of the bracket. A notch or slot 210 is cut into the inner edge vertical leg 120 of the blank 200″, as shown in FIG. 10, at a height above the upper bend line 206 that equals the full edge-to-edge face width of the smaller of the two compatible rail sizes. In the finished bracket 10″, 10A″, this creates a gap 19 between the two shoulder flanges 18A, 18B at a height above the seating flange 16 that equals the edge-to-edge face width of the smaller of the two compatible rails sizes. So, in the illustrated embodiment intended for use with either 2×4 or 2×6 rails, the gap 19 is s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap