Electrostatic atomization device

a technology of electrostatic atomization and atomization chamber, which is applied in the direction of electrostatic spraying apparatus, burners, lighting and heating apparatus, etc., can solve the problems of unstable discharge and difficulty in solving the electrostatic atomization device, and achieve the effect of effectively preventing the surplus production of condensed water and preventing the cooling capability from being lowered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

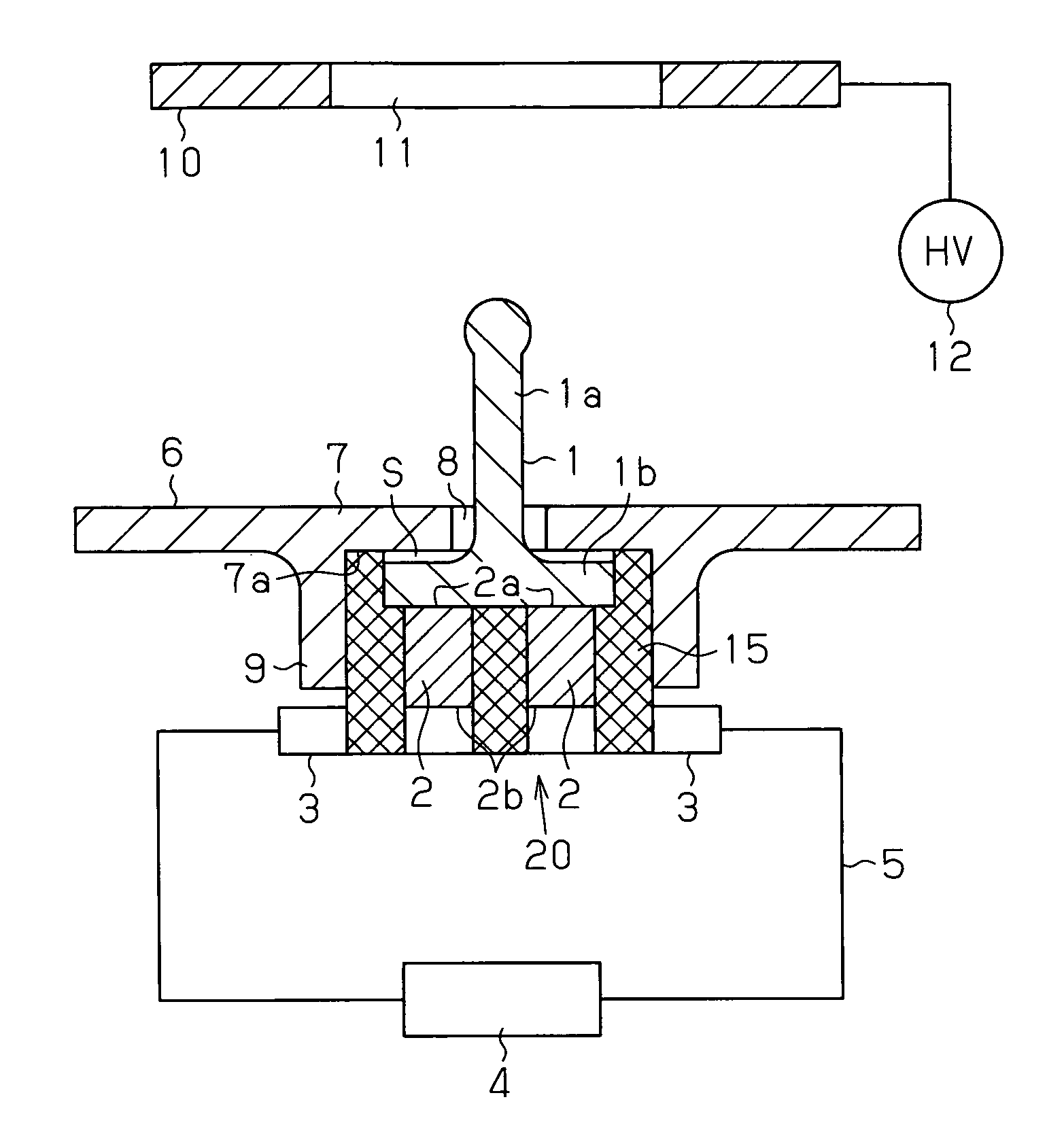

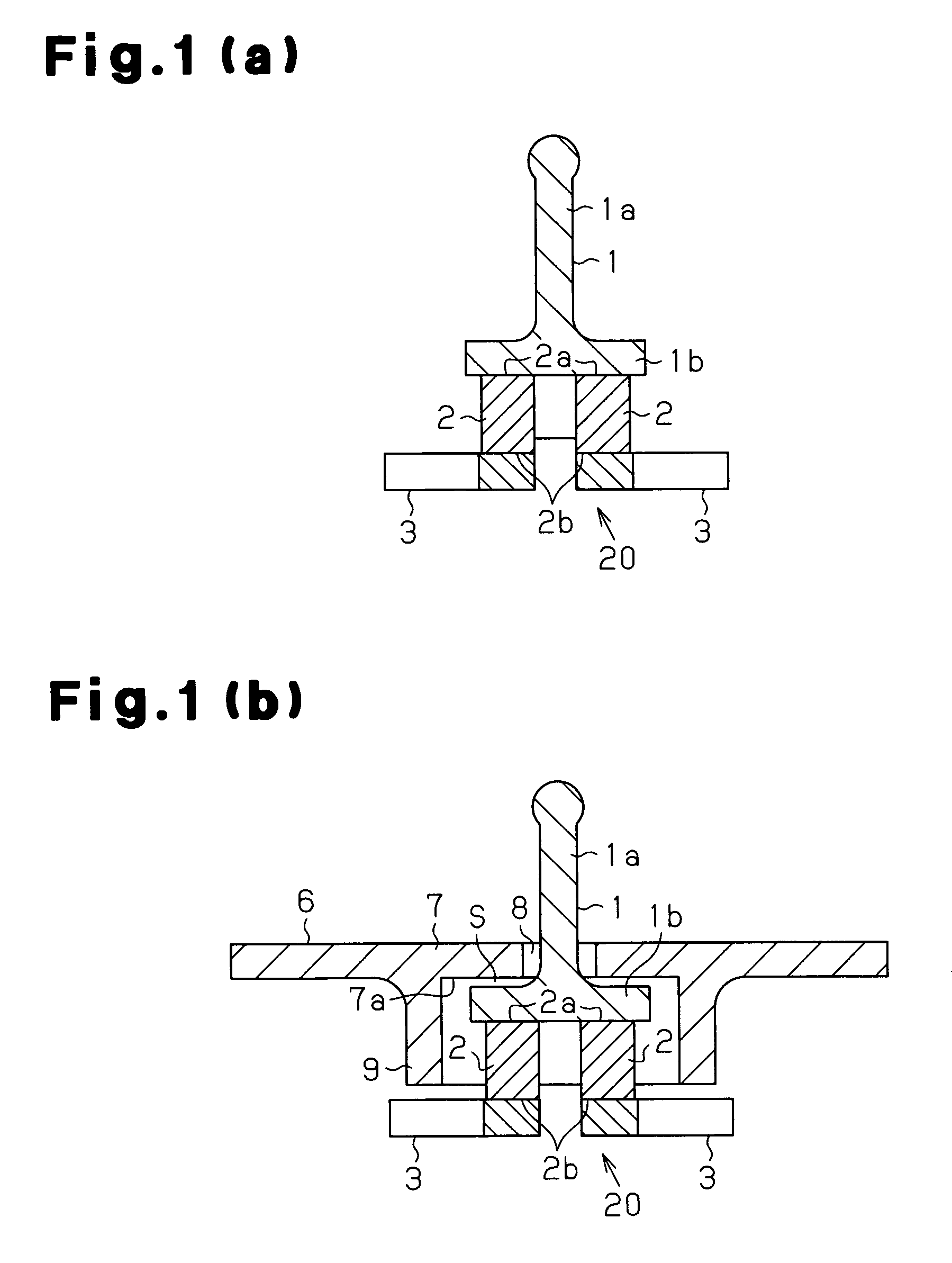

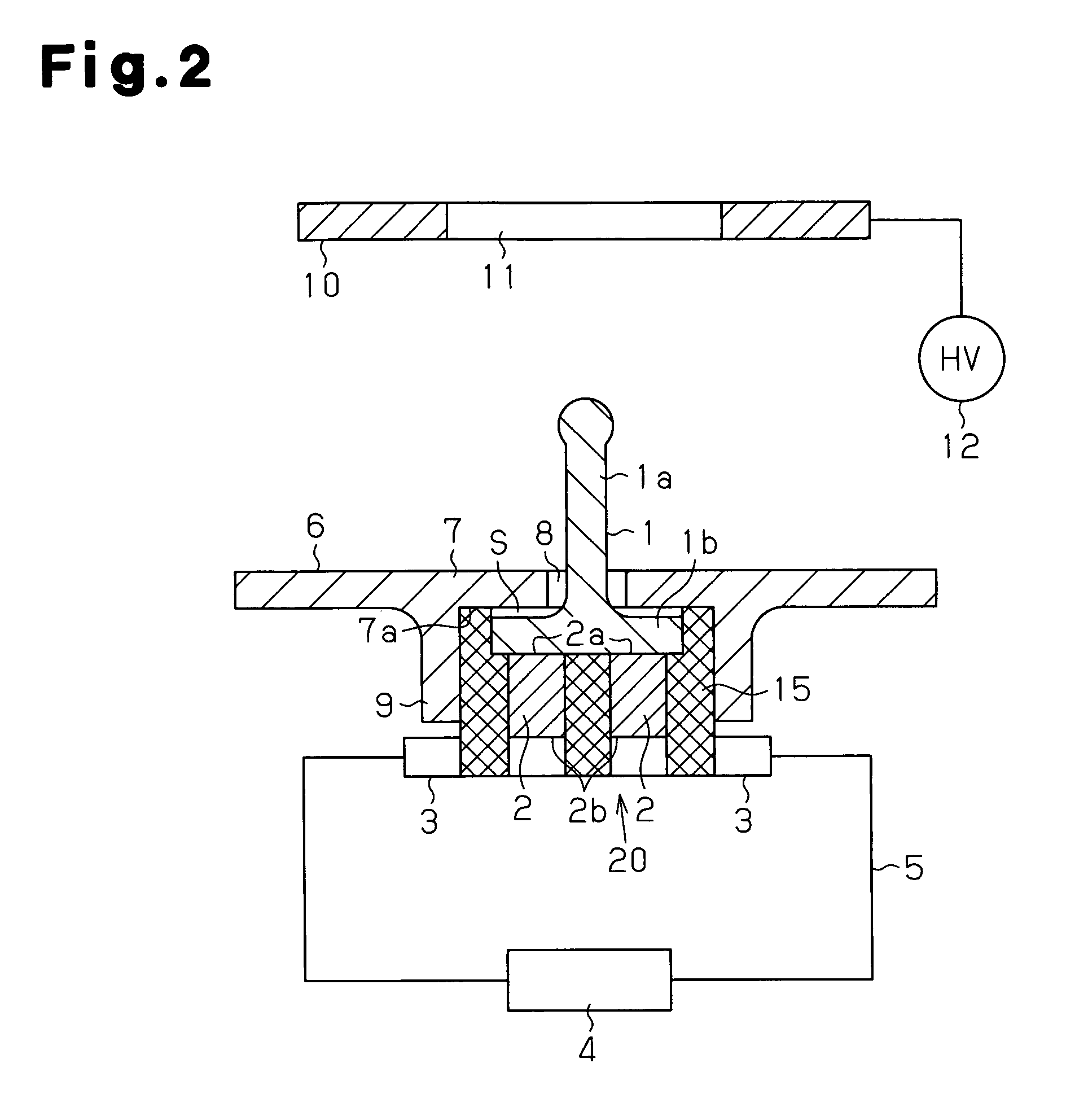

[0014]An electrostatic atomization device according to one embodiment of the present invention will now be discussed with reference to the drawings. FIGS. 1 and 2 show one example of the basic structure of the electrostatic atomization device.

[0015]The electrostatic atomization device includes a cooling unit 20, which serves as a cooling means for cooling an atomization electrode 1. The cooling unit 20 includes a pair of thermoelectric elements 2. The pair of thermoelectric elements 2 includes a P type thermoelectric element and an N type thermoelectric element. Each thermoelectric element has a heat absorption surface 2a and a heat dissipation surface 2b. The heat absorption surface 2a is connected to the atomization electrode 1.

[0016]More specifically, the heat absorption surfaces 2a of the two thermoelectric elements 2 are mechanically and electrically connected to a bottom surface of a base 1b of the atomization electrode 1. The heat dissipation surface 2b of each thermoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com