Compact weight lifting machine

a weight lifting machine and compact technology, applied in the field of physical fitness boom, can solve problems such as bidirectional activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

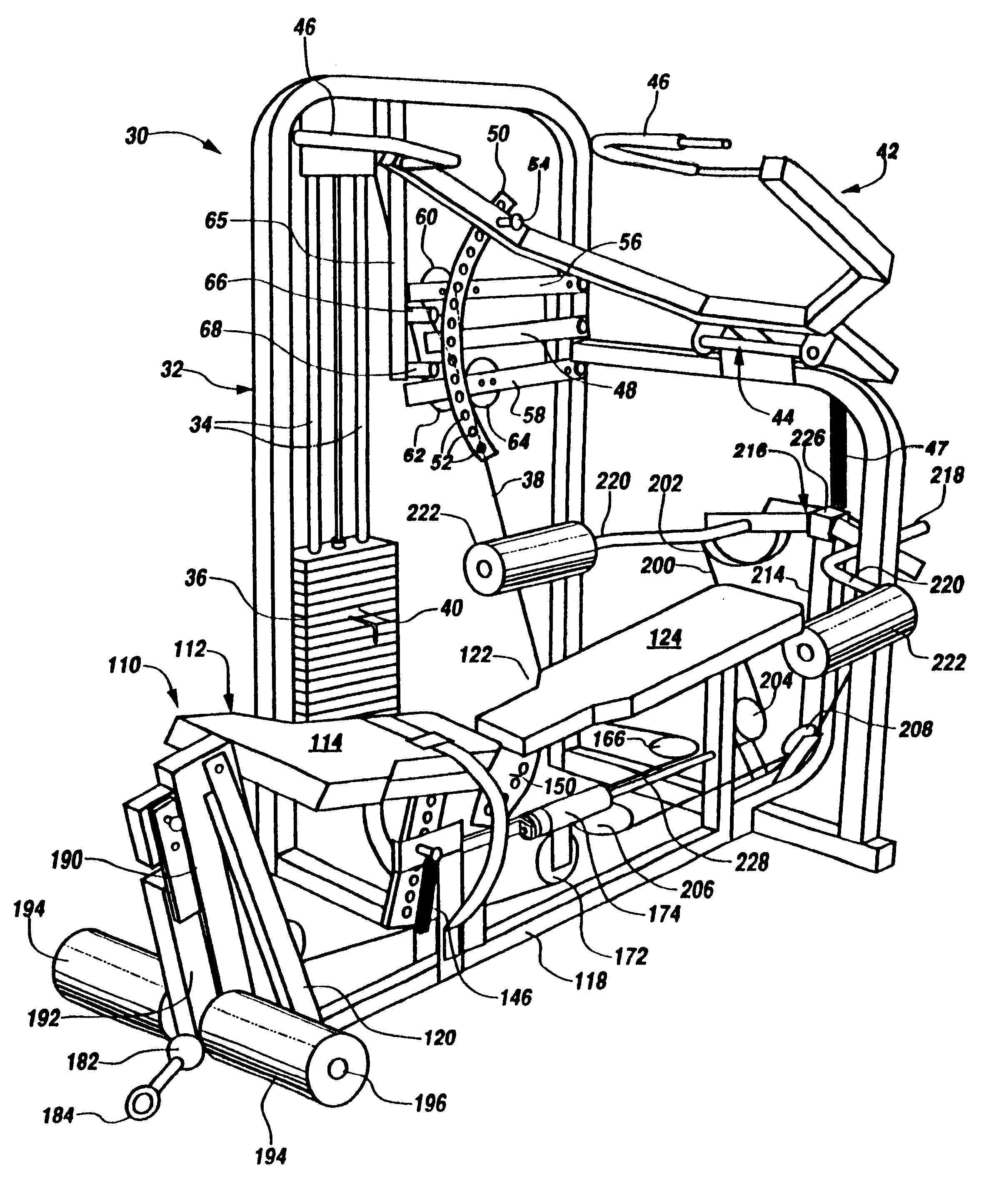

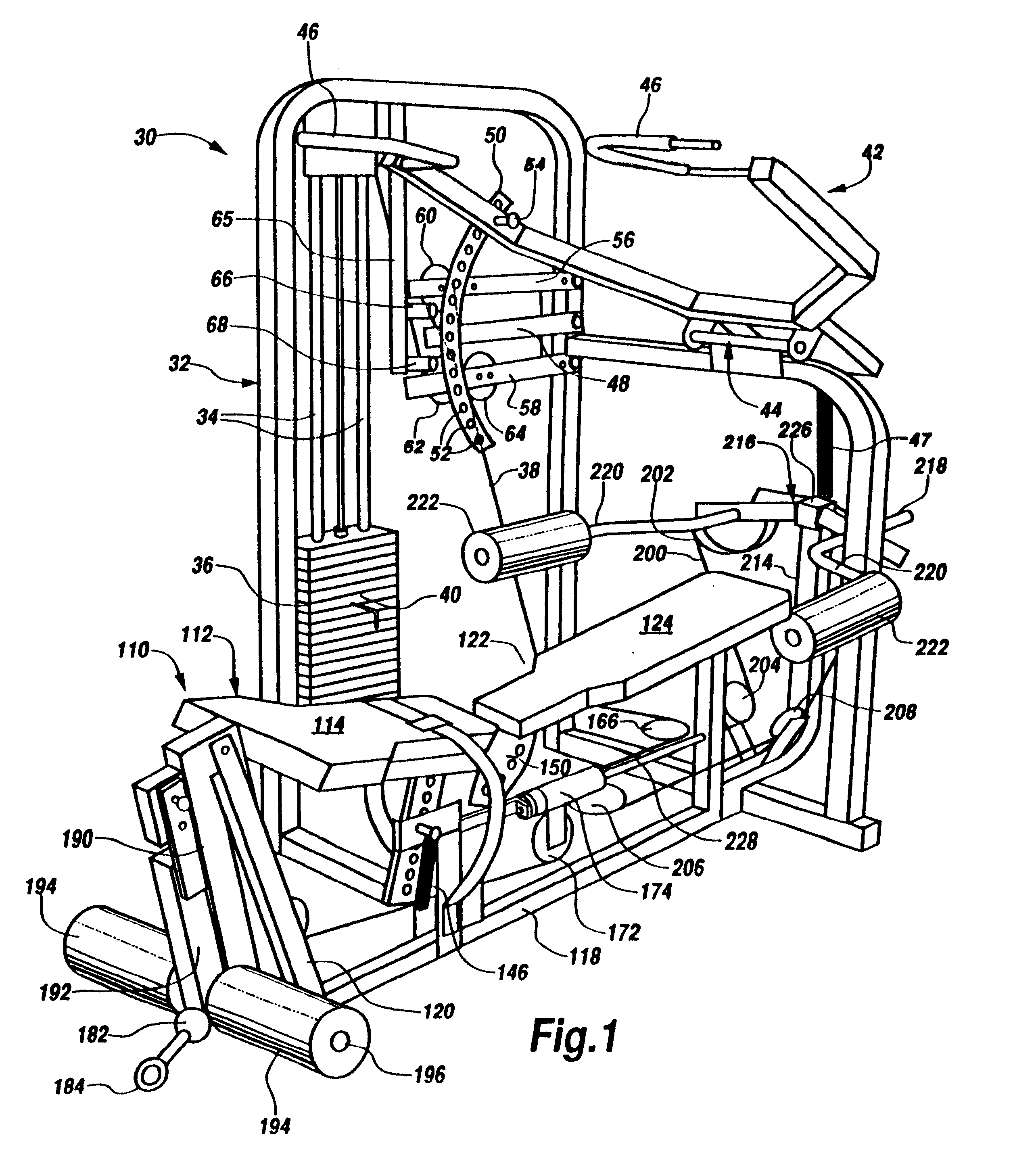

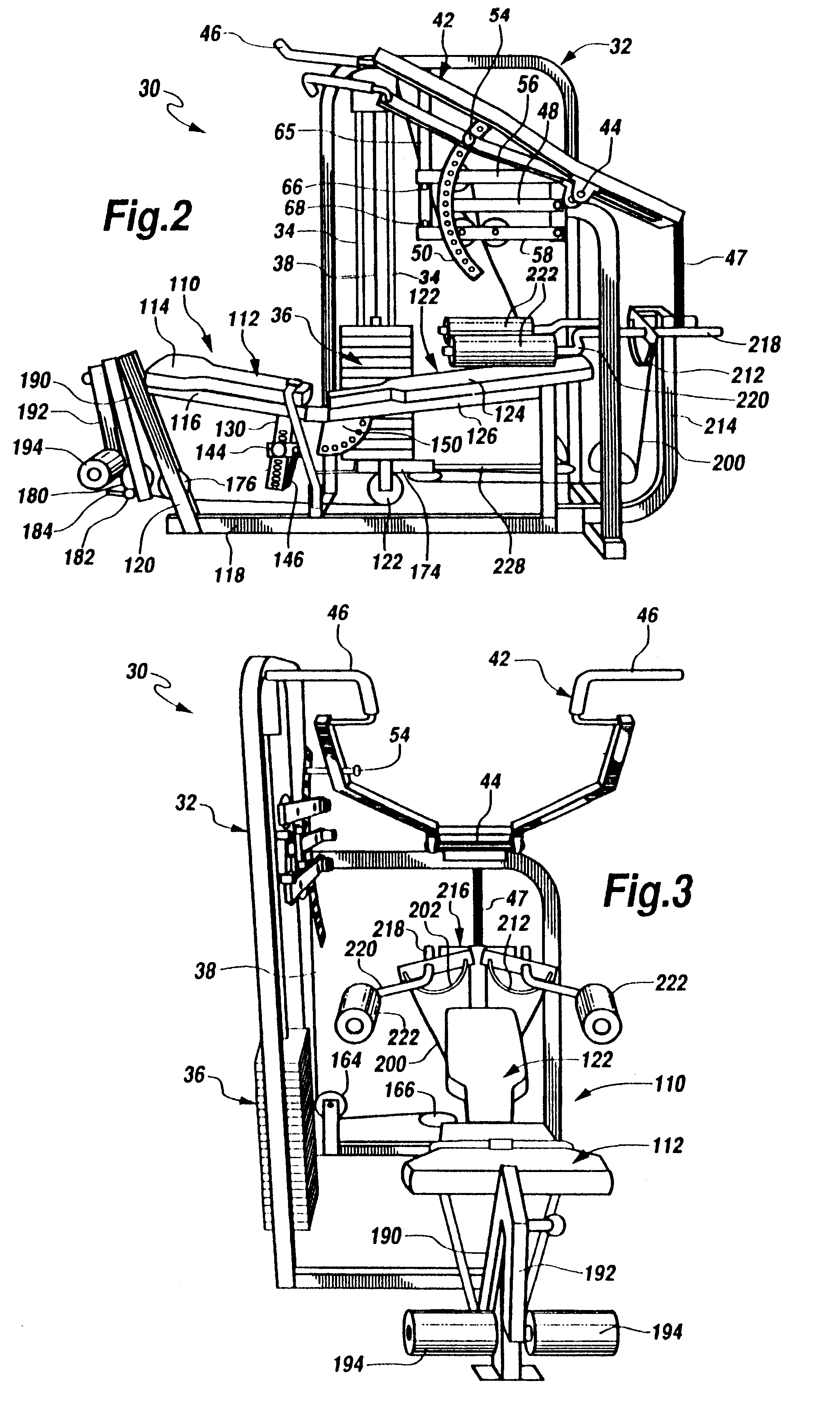

Referring now to the Drawings, and particularly to FIGS. 1, 2 and 3 thereof, there is shown a compact weight lifting machine 30 incorporating the present invention. The machine 30 comprises a frame 32 which supports and positions the various component parts thereof. The frame 32 is conventional in nature and comprises a plurality of interconnected sections of tubing. The tubing sections comprising the frame 32 may be formed from stainless steel or other conventional materials, and may have a square, rectangular, or any other desired cross sectional configuration. The tubing sections comprising the frame 32 are preferably cut, bent, and welded or otherwise secured together using conventional techniques.

The frame 32 includes a pair of vertically extending guides 34. A conventional weight stack 36 comprises a plurality of individual weights which may be formed from cast iron and which are slidably supported on the guides 34 for vertical movement thereon against the action of gravity. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com