Air pressure forming method for producing glass fibre reinforced plastic

A technology of air pressure forming and manufacturing method, which is applied in the field of FRP air pressure forming and manufacturing for producing FRP products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] According to the foregoing, the present invention coats resin and fiber between the hard outer mold and the soft inner mold, fixes the mold gland after sealing, inflates and pressurizes or puts the inner and outer molds sealed with sealing bead into pressure-resistant In the container, it can be solidified by inflating and pressurizing or after the hard outer mold and the soft inner mold are sealed and pressurized, the thermosetting resin or thermoplastic resin can be molded by heating and curing or cooling.

[0008] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

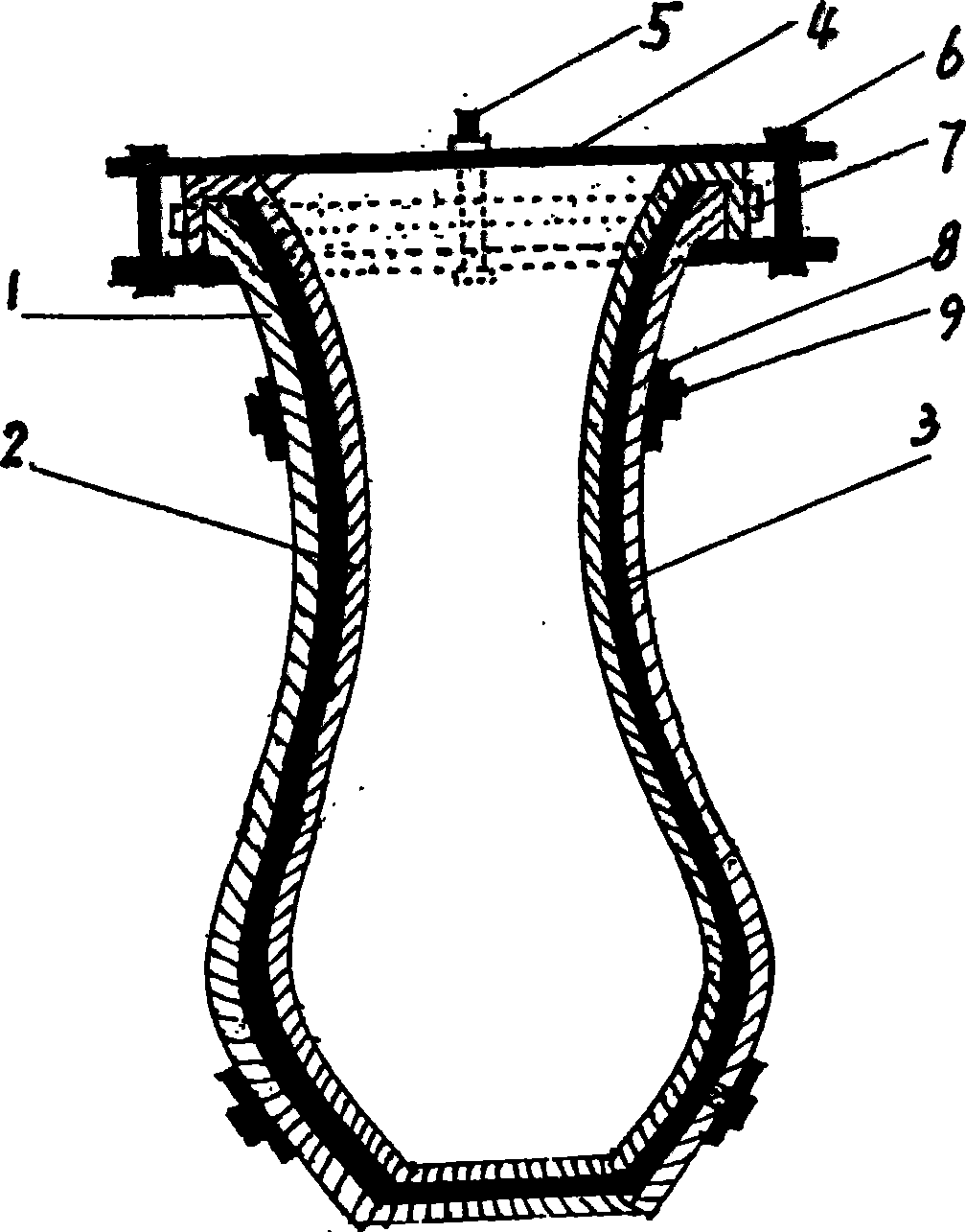

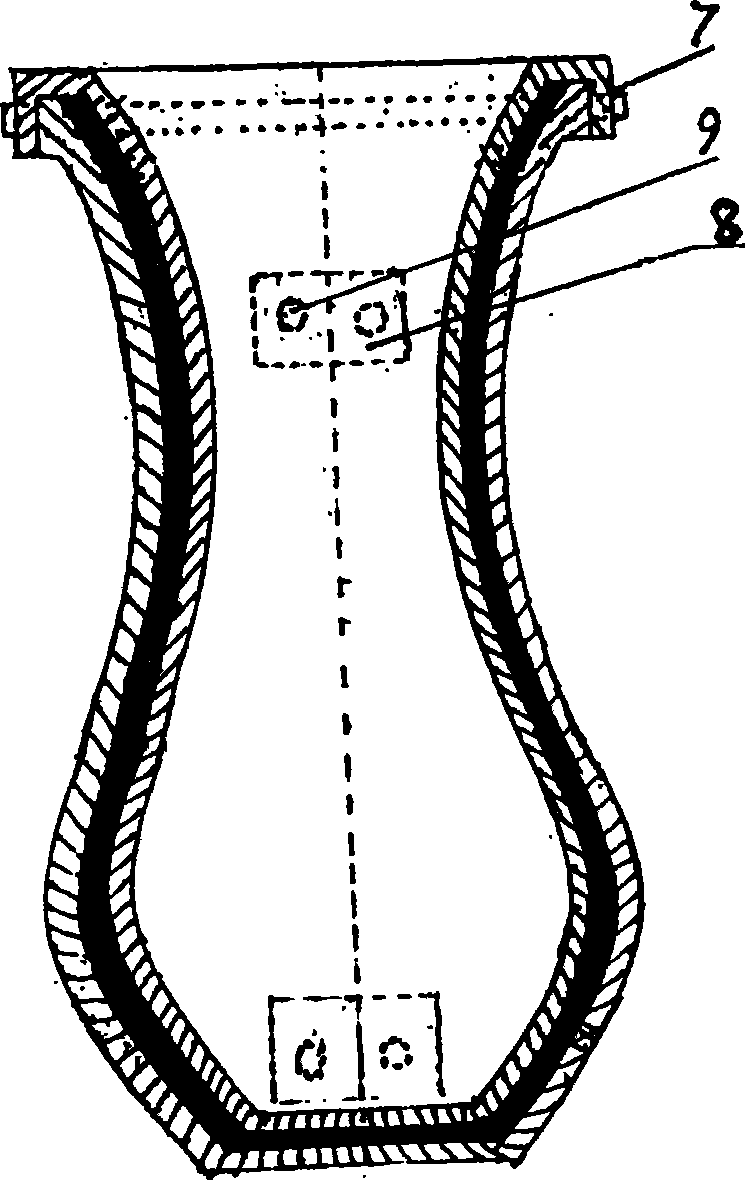

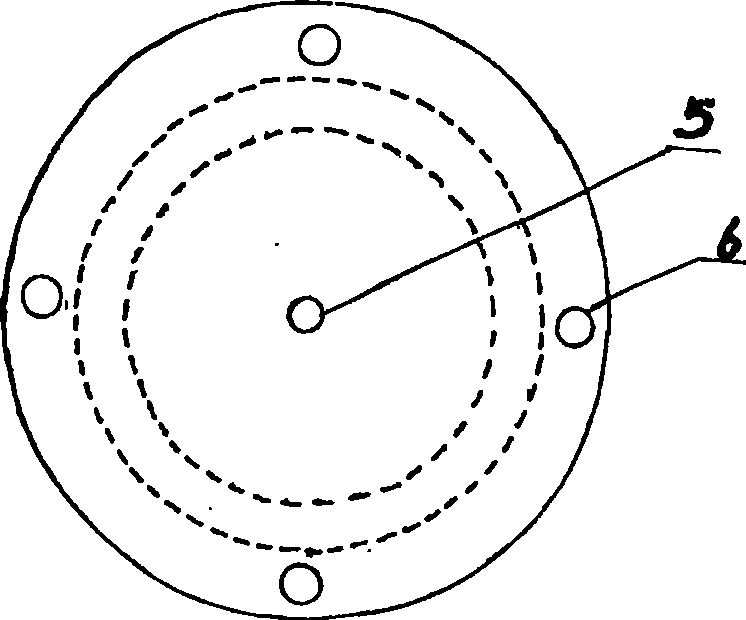

[0009] figure 1 , figure 2 The molding process and mold diagram of the vase with large inner mold cavity and small outer diameter are given. Depend on figure 1 , figure 2 Shown, the present invention is, the fixing member bolt 9 is pressed against the mold fixing member 8, and the hard outer mold 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com