Rubber-plastic composite bush

A bushing, rubber-plastic technology, used in springs, bearing elements, springs/shock absorbers, etc. made of plastic materials, can solve the problem of large torque and wear, uneven stress on the rubber layer, and poor shock absorption performance and other problems, to achieve the effect of small friction coefficient, light weight and low wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

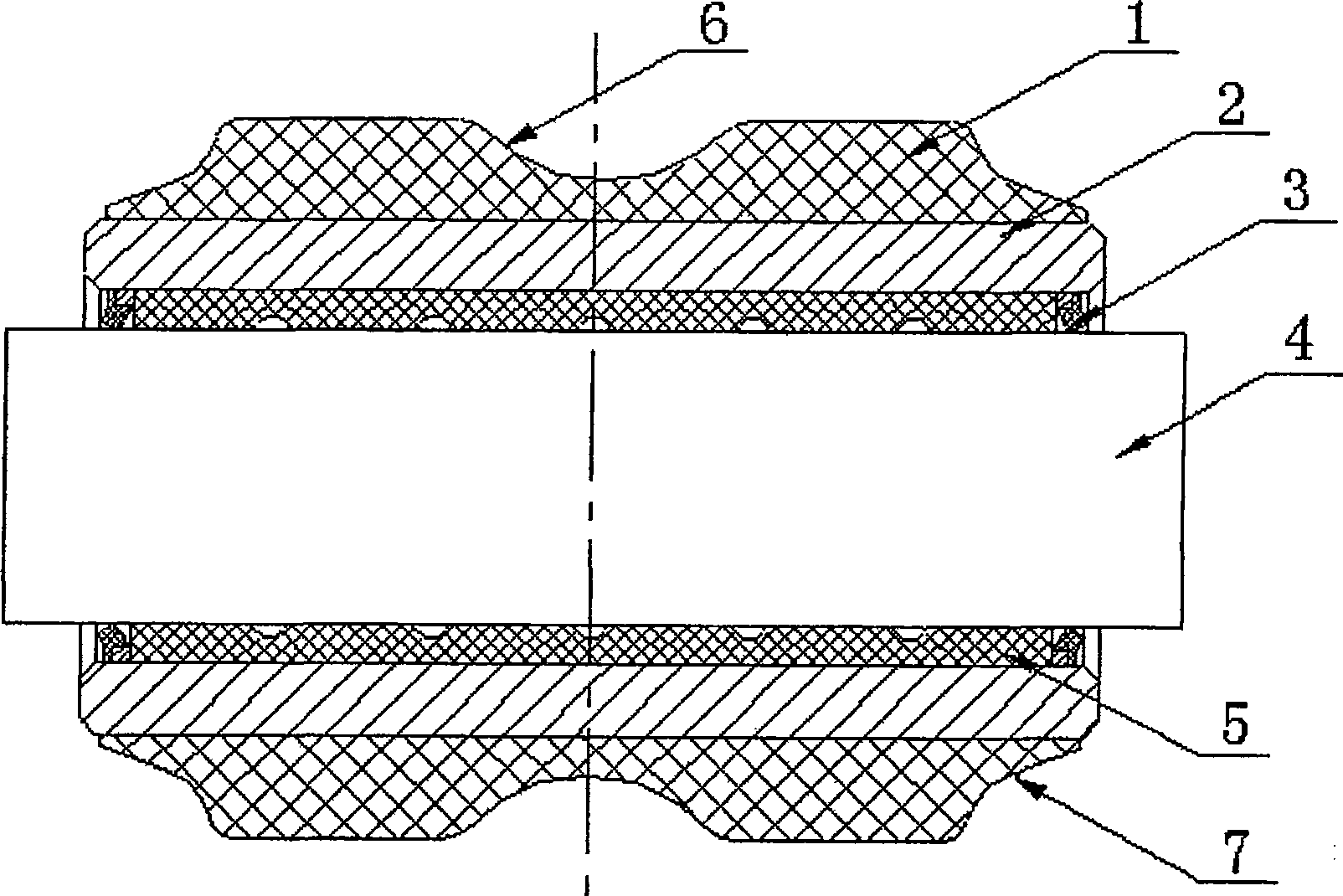

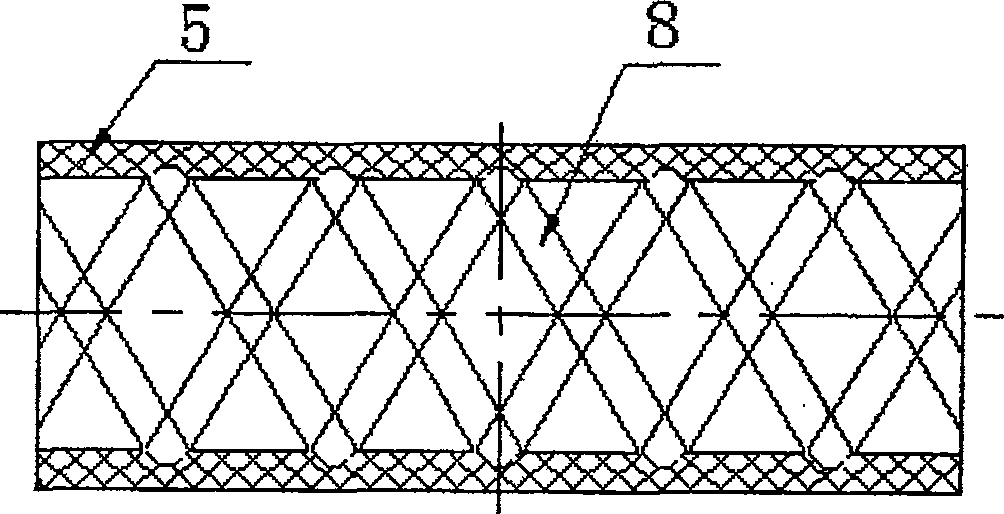

[0027] see figure 1 , a rubber-plastic composite bushing, including a rubber sleeve body 1 and a steel sleeve 2, the rubber sleeve body 1 is fixed on the outer cylindrical surface of the steel sleeve 2, and a plastic bushing 5 is fixed in the inner hole of the steel sleeve 2. The rubber sleeve body 1 is vulcanized and bonded on the outer layer of the steel sleeve 2, that is, the surface of the outer cylinder, to form a rubber bushing. The plastic bushing 5 is pressed into the inner hole of the steel bushing 2 with a certain amount of interference to form a rubber-plastic composite bushing assembly. Install the metal shaft pin 4 that cooperates with it in the plastic bushing 5 inner holes then.

[0028] see figure 1 , Figure 6 , the outer cylindrical surface of the middle part of the rubber sleeve 1 is provided with at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com