Inverter

A technology for inverter devices and industrial machines, applied in the direction of converting irreversible DC power input into AC power output, etc., can solve problems such as stop operation, cannot continue, need time and energy, and achieve the effect of preventing operation stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

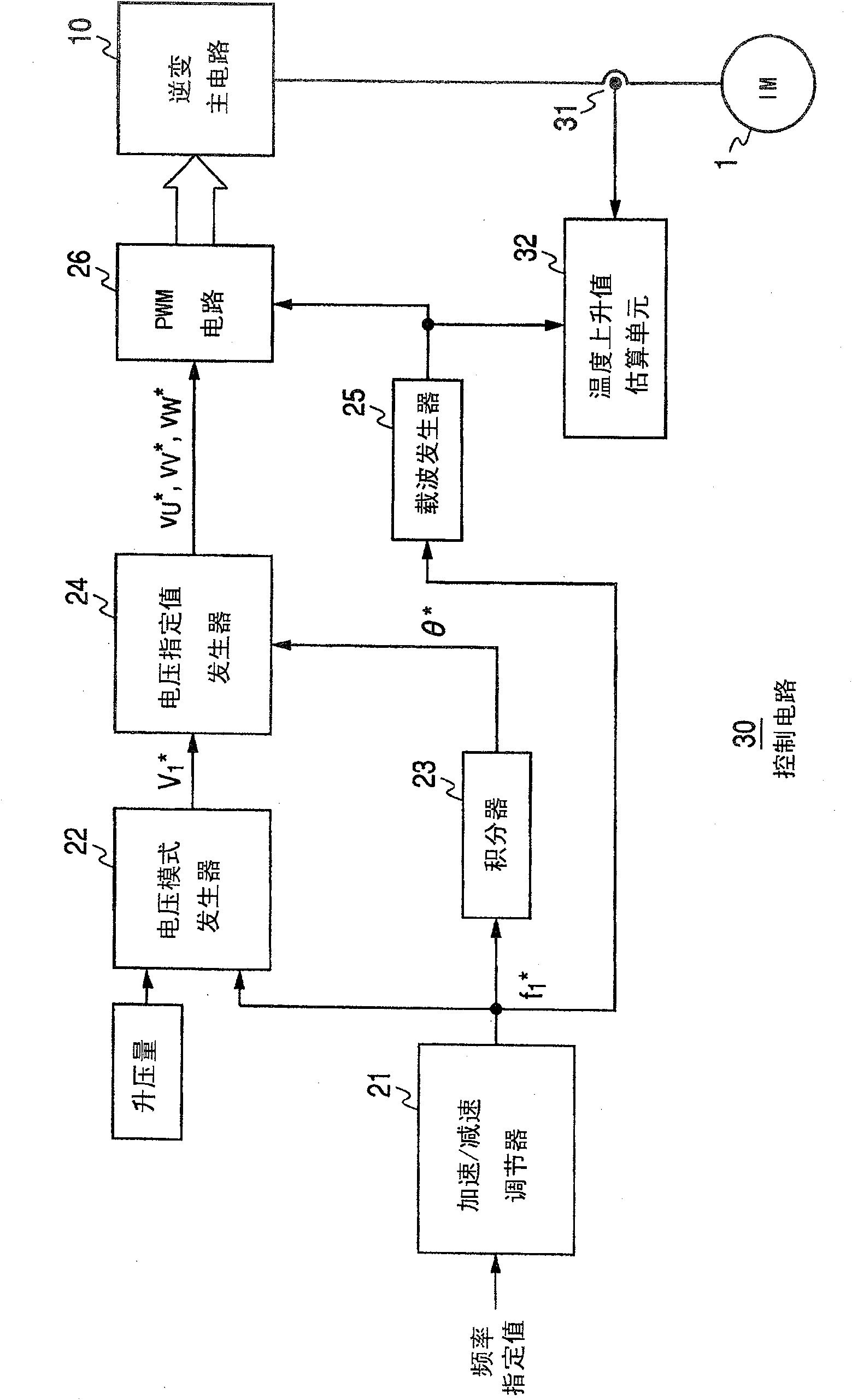

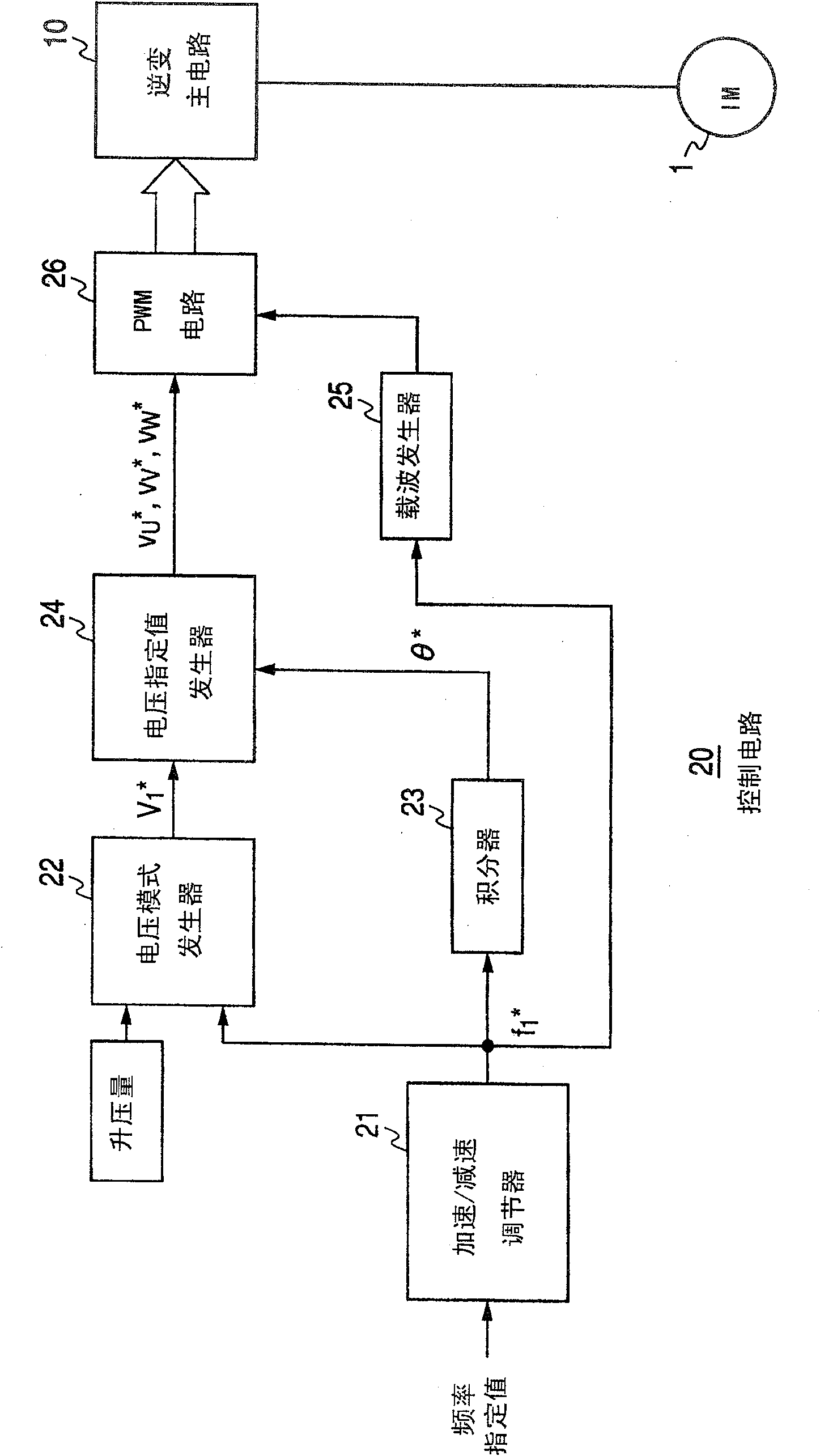

[0019] figure 1 is a circuit diagram of an inverter device according to an embodiment of the present invention. have with image 3 Elements of the same function in the conventional circuit shown are labeled with the same reference numerals and will not be described in detail again.

[0020] figure 1 The inverter device shown has a control circuit 30, which passes through the image 3 A current detector 31 and a temperature rise estimation unit 32 are additionally provided in the control circuit 20 to form.

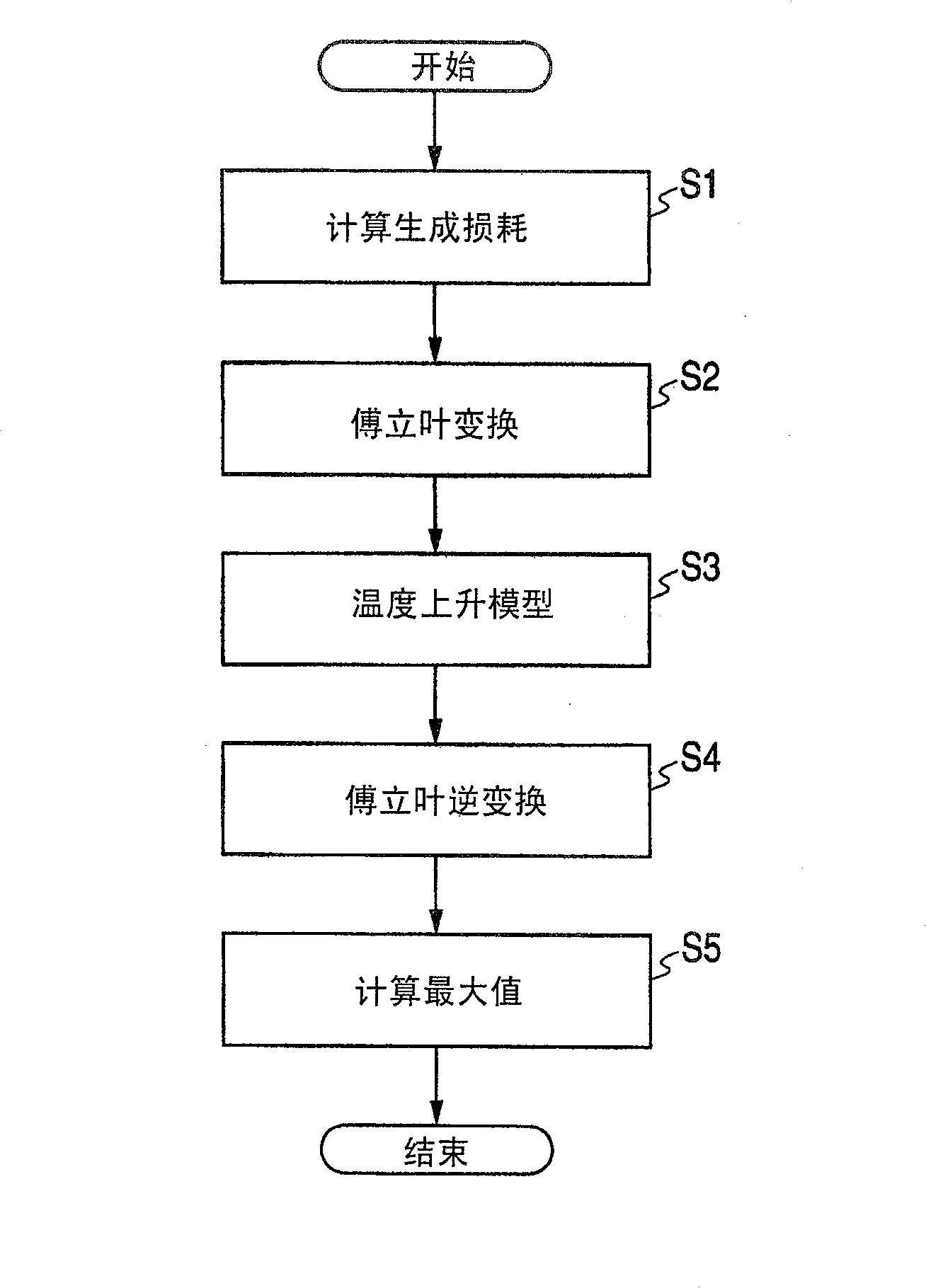

[0021] will be referred to below figure 2 Flowchart description of figure 1 The operation of the temperature rise value estimating unit 32 is shown.

[0022] use figure 1 The temperature rise value estimating unit 32 of the inverter device is shown, and the operating mode of one cycle in the industrial machine is observed by the inverter device, and the inverter circuit 13 that constitutes the inverter main circuit 10 is derived based on the observation data (see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com