High-efficiency fungicide for papermaking white water

A paper-making white water and fungicide technology, applied in the direction of fungicides, biocides, biocides, etc., can solve the problems of product toxicity, antibacterial effect, cost of use, and the difficulty of adapting to the needs of the range of use and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 4L of the above isothiazolinone derivatives and 12L of 1227 (quaternary ammonium salt cationic surfactant) respectively, mix well, add 672 grams of magnesium chloride, stir evenly, and seal in the container. That is to make a high-efficiency fungicide for papermaking white water. The actual compound content of the fungicide is: 2.8% of 5-chloro-2-methylisothiazolin-3-one, 2-methylisothiazolin-3-one 0.70%, 33.8% of dodecyl dimethyl benzyl ammonium chloride, 4.2% of magnesium chloride, and the balance is water.

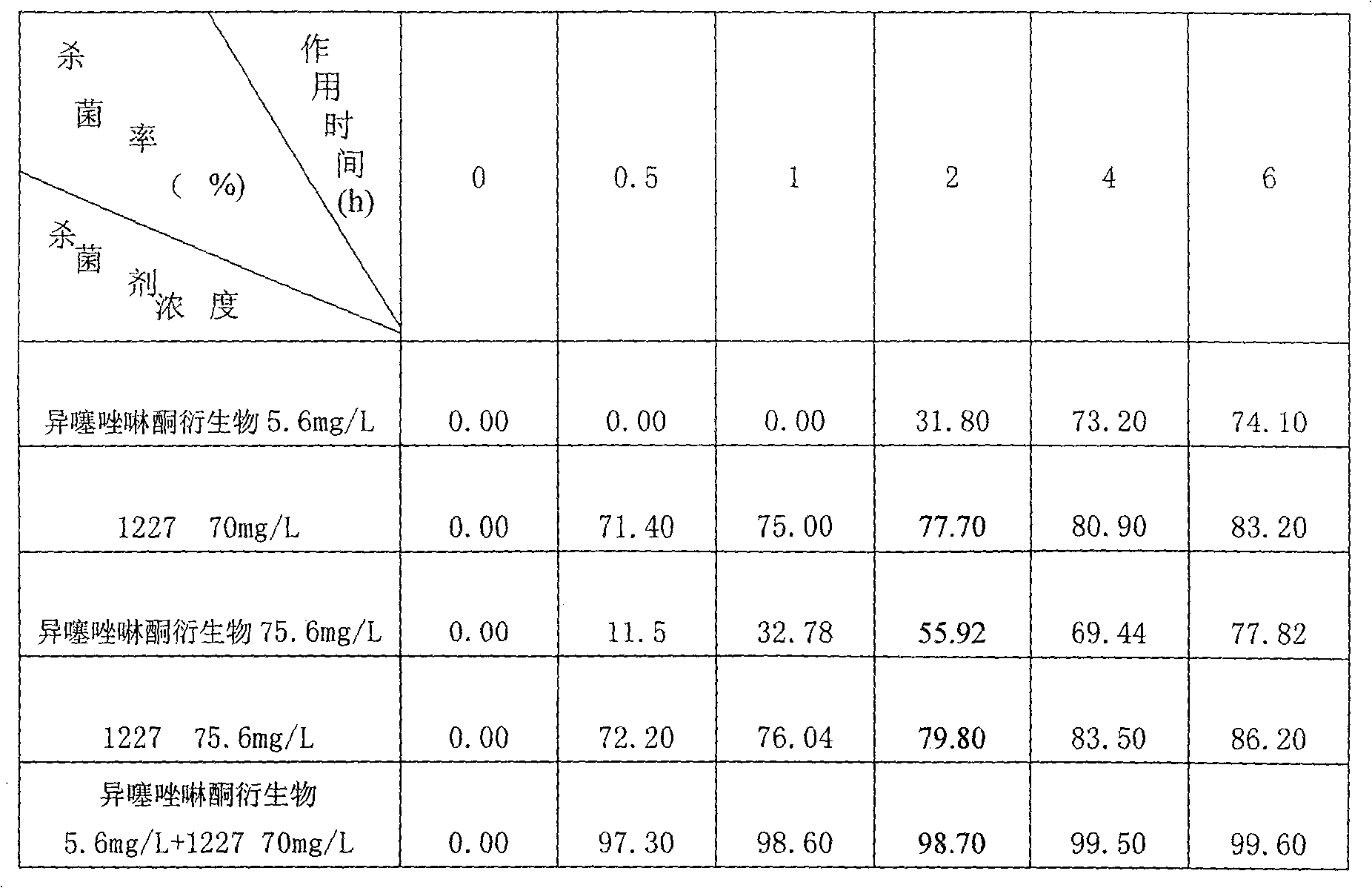

[0026] Bactericidal application test on papermaking white water: the papermaking white water circulating water in paper mills has been tested and the total number of microorganisms is 1.0×10 8 cfu / mL. Take 7L of the above-mentioned high-efficiency bactericide for papermaking white water, add it to the above papermaking white water circulating water with a total volume of 20 tons, and take a sample after 4 hours to determine that the total number of microorg...

Embodiment 2

[0029]Take 4 L of the above isothiazolinone derivatives and 16 L of dodecyldimethylbenzyl ammonium chloride respectively, mix well, add 900 g of magnesium chloride, stir evenly, and seal them in a container. That is to make a high-efficiency fungicide for papermaking white water. The actual compound content of this kind of fungicide is: 2.24% of 5-chloro-2-methylisothiazolin-3-one, 2.24% of 2-methylisothiazolin-3-one 0.56%, 36% dodecyl dimethyl benzyl ammonium chloride, 4.5% magnesium chloride, and the balance is water.

[0030] Bactericidal application test on papermaking white water: the papermaking white water circulating water in paper mills has been tested and the total number of microorganisms is 8.9×10 7 cfu / mL. Get 2.5L of this special fungicide for white water, add it to the above papermaking white water circulating water with a total volume of 20 tons, and take a sample after 6 hours to determine that the total number of microorganisms in the papermaking white water...

Embodiment 3

[0033] Separately take 2 L of isothiazolinone derivatives and 10 L of dodecyldimethylbenzyl ammonium chloride, mix thoroughly, add 590 g of magnesium nitrate, stir evenly, and seal them in a container. That is to make a special fungicide for papermaking white water, the actual compound content of this kind of fungicide is: 1.84% of 5-chloro-2-methylisothiazolin-3-one, 1.84% of 2-methylisothiazolin-3-one 0.46%, dodecyl dimethyl benzyl ammonium chloride 37.5%, magnesium nitrate 4.92%.

[0034] Bactericidal application test on papermaking white water: the papermaking white water circulating water in paper mills has been tested and the total number of microorganisms is 9.4×10 7 cfu / mL. Get 4L of this special bactericide for white water, join the above papermaking white water circulating water with a total volume of 20 tons, and take a sample after 4 hours to determine that the total number of microorganisms in papermaking white water is 1.3×10 6 cfu / mL, the bactericidal rate rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com