Saw band torsional mechanism of band-saw machine

A technology of band sawing machines and sawing bands, which is applied in the direction of band saws, sawing machine devices, sawing machine attachments, etc., which can solve the problems of finger injury and cumbersomeness, and achieve the effects of improved torsion characteristics, convenient belt replacement, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

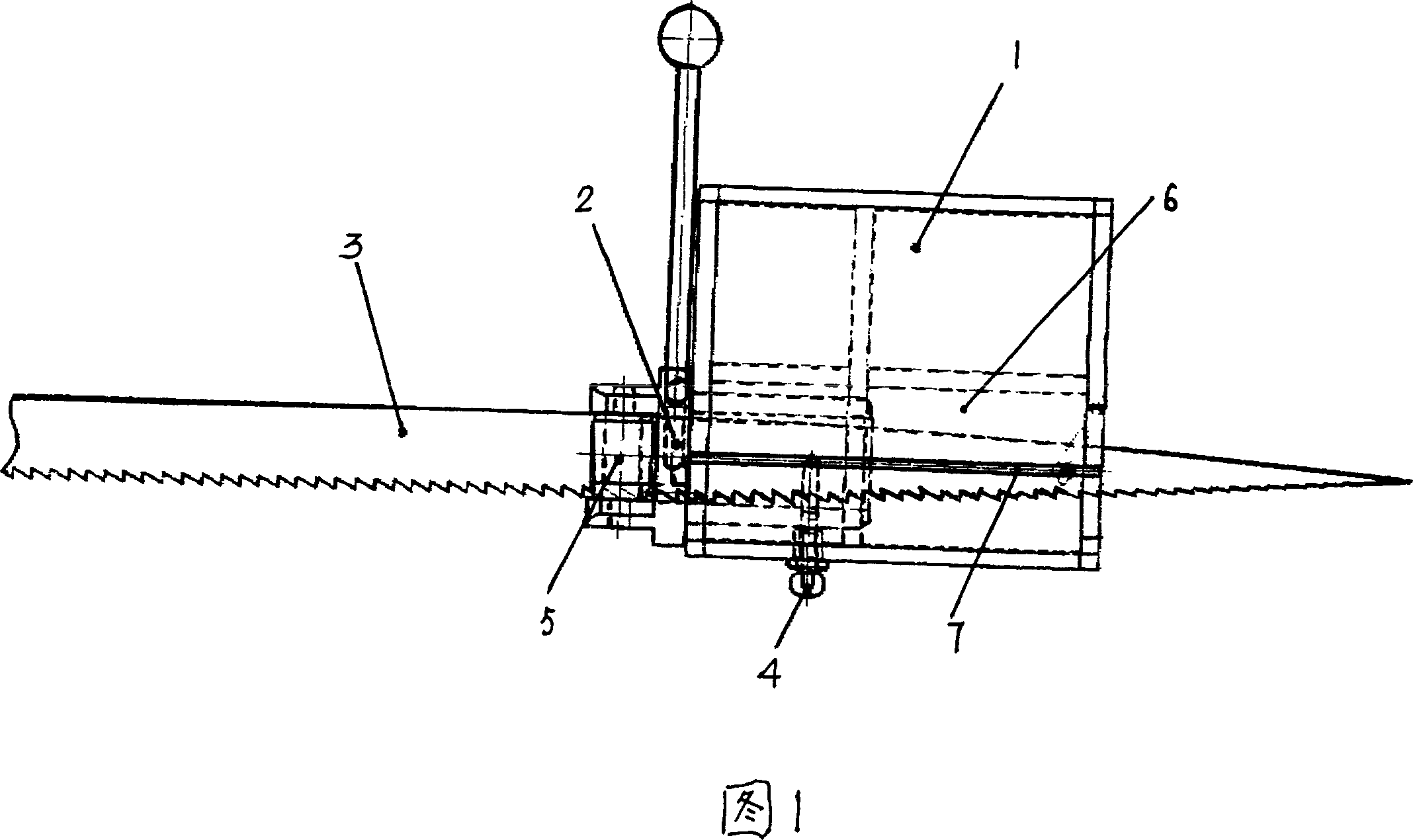

[0009] Referring to Fig. 1, a saw band twisting mechanism for a band sawing machine has a shell 1, and a circular hole 6 is formed in the shell 1, and a belt loading groove 7 is formed on one side of the circular hole 6, and the twisting body 2 is installed In the circular hole 6, the torsion body 2 is formed with a groove with a single side opening and corresponding to the tape loading groove 7 in the circular hole 6, the rolling pair 5 is fixed on the torsion body 2, and the housing 1 is also equipped with Lock in place 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com