Jetting out method for molding bicolor plastic cement

An injection molding and two-color molding technology, which is applied in the field of two-color plastic injection molding, can solve the problems of product yield decline and unsightly appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

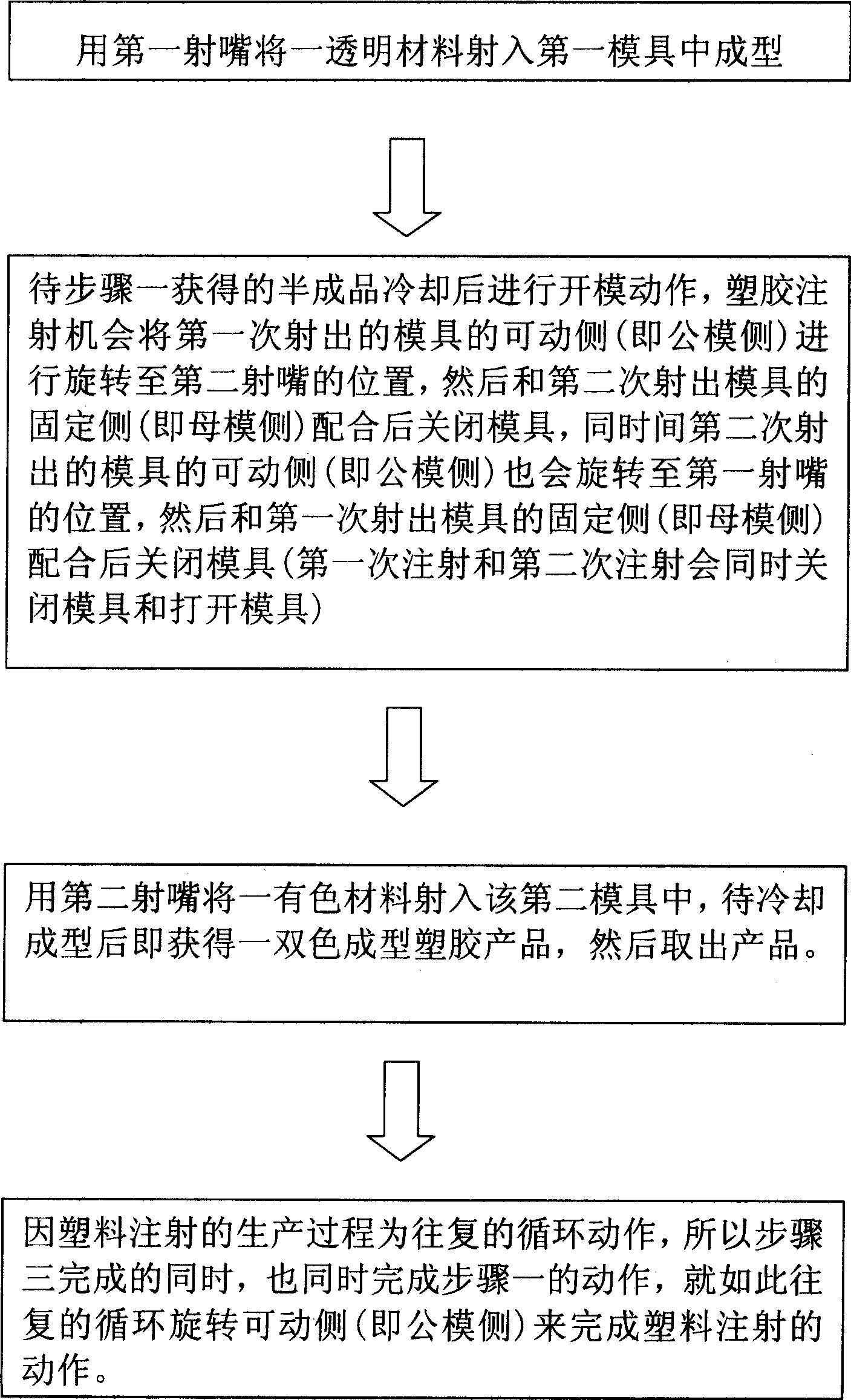

[0014] Please refer to FIG. 1 , a two-color plastic injection molding method is used to produce a two-color molded plastic product, which requires a plastic injection machine, which includes two molds and two nozzles. Each nozzle corresponds to independent feeding, heating, injection and other devices.

[0015] In this embodiment, the two-color molded plastic product includes a transparent material part and a non-material part. The transparent material part is formed with the first mold, and the opaque material part is formed with the second mold. The first nozzle is used to eject the transparent material, and the second nozzle is used to eject the non-transparent material.

[0016] The two-color plastic injection molding method of the present invention comprises the following steps:

[0017] Step 1: first close the mold (the first injection mold and the second injection mold), and use the first nozzle to inject a transparent material into the first mold for molding;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com