Method of controlling curve profile of bridge steel column

A technology for bridge steel towers and steel tower columns, which is applied in the field of curve control of curved steel tower columns in steel structure bridges to achieve novel and beautiful shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

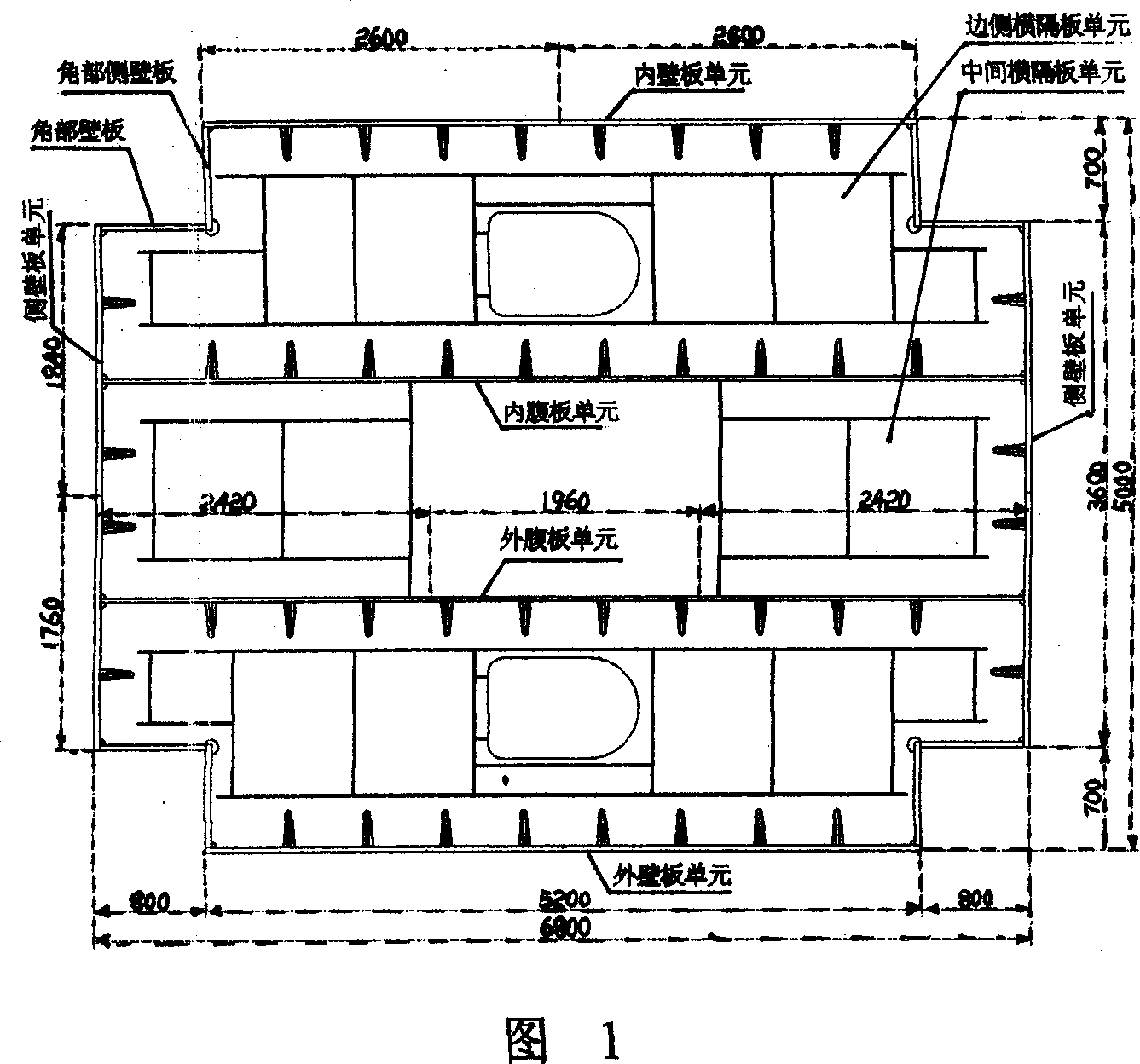

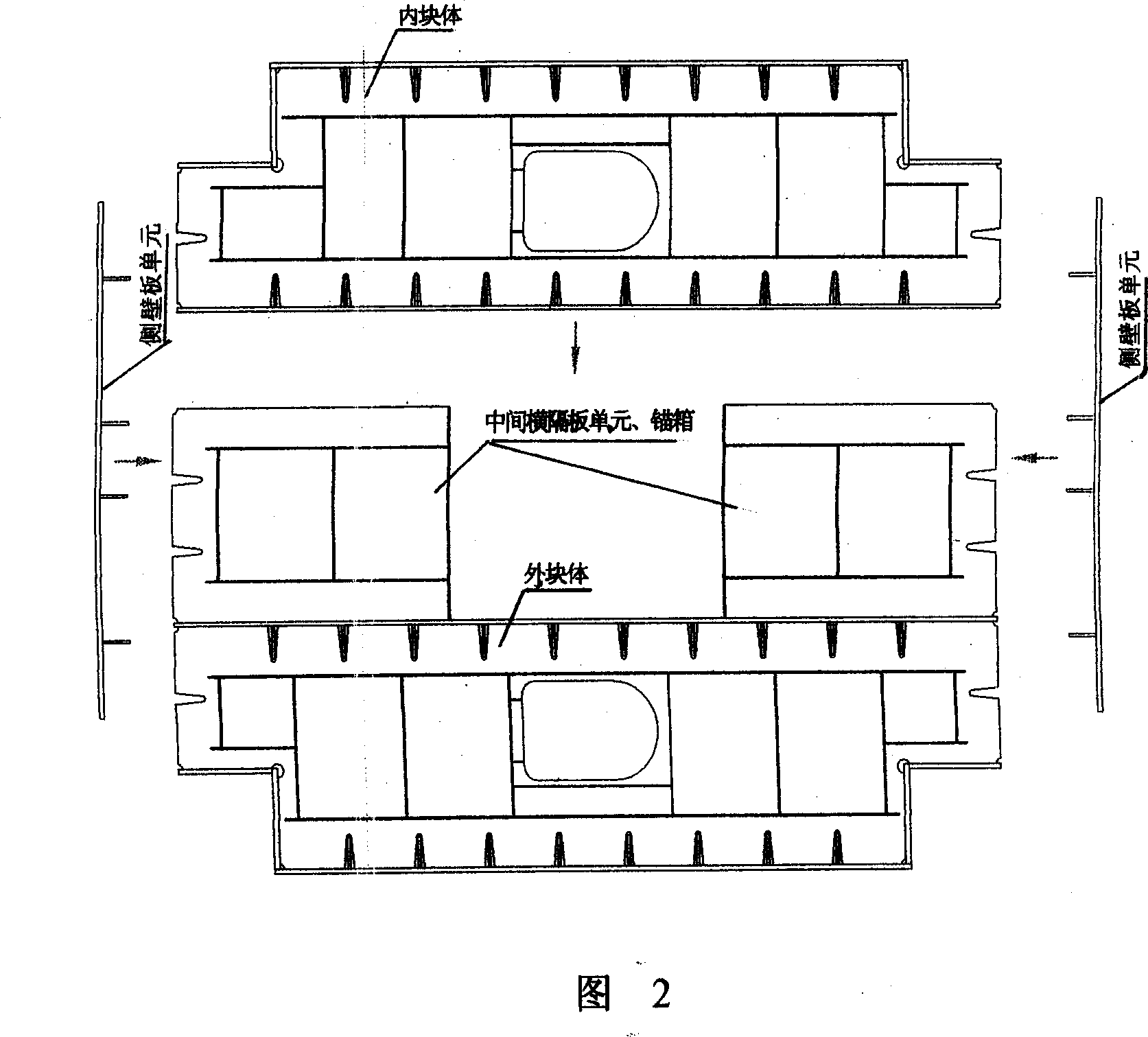

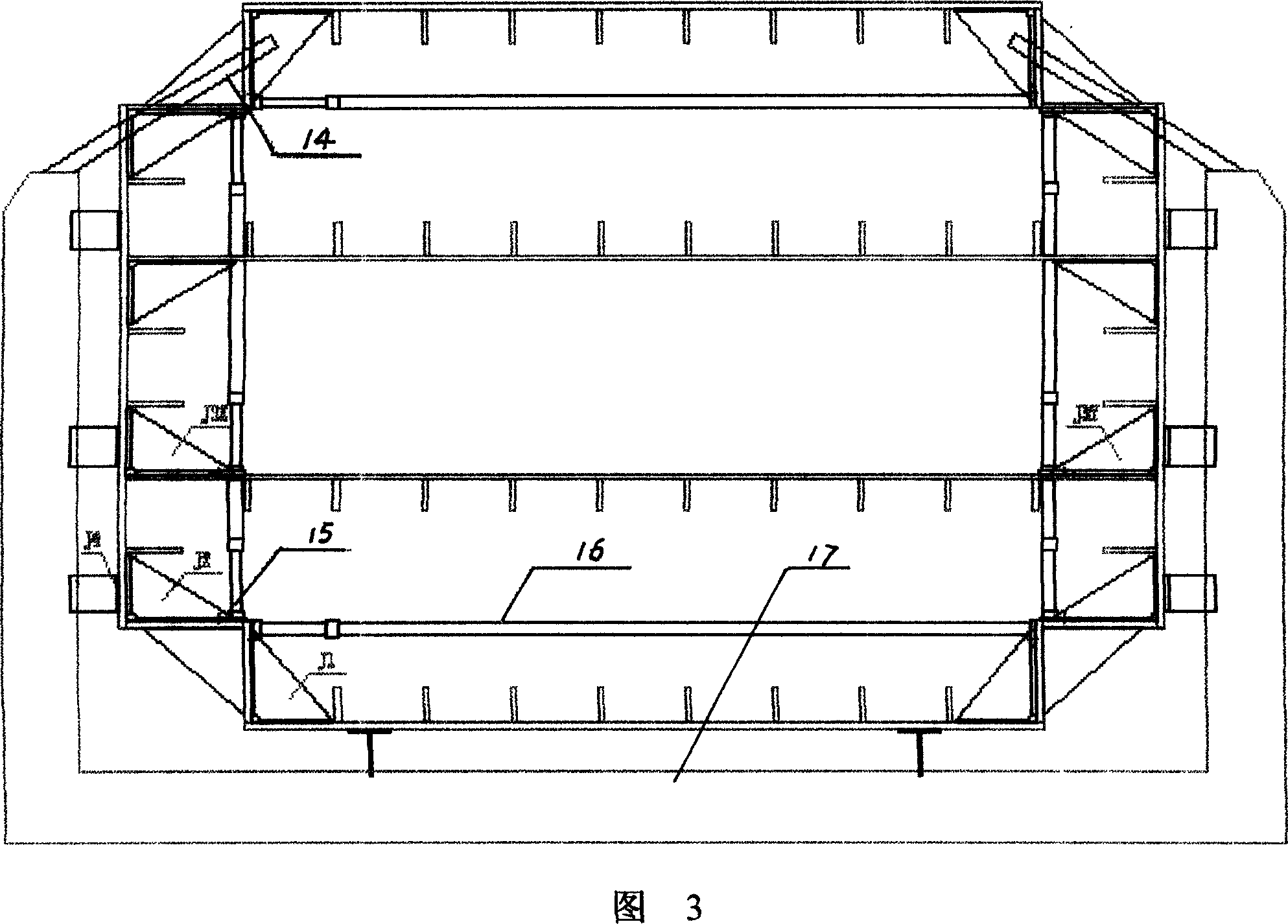

[0021] Specifically, a bridge steel tower column with a curved shape, the steel tower column is formed by connecting several curved steel tower segments, and the curve shape of each segment is in line with the curve of the overall position of the steel tower column corresponding to the line. The inner and outer wall plate units (13, 9) and the inner and outer web plate units (11, 10) in the steel tower segment in the plate thickness direction are arc-shaped curves; the side wall plate units (8) on both sides in the plate width direction are arc-shaped The arc shape matches the curve shape of the inner and outer wall panels and the inner and outer web plates; at the same time, the arc curve corresponds to the curve shape of the steel tower column as a whole. The steel tower segment is composed of an inner wall plate unit (13), an inner web plate unit (11), an outer wall plate unit (9), an outer web plate unit (10) and side wall plate units (8) on both sides, a transverse The l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com