Toner and method for producing the same

一种墨粉、粉状的技术,应用在生产墨粉领域,达到容易生产、生产效率和经济效率优良、生产和经济效率优良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0153] Preparation of Toner Material

[0154] [113] 50% by mass of polyester resin, 30% by mass of styrene-acrylate copolymer, 15% by mass of carbon black, 4.5% by mass of wax and 0.5% by mass % of the charge control agent is melt-kneaded, cooled, solidified, and then roughly ground with a hammer mill to prepare a toner raw material.

[0155] Grinding and Grading

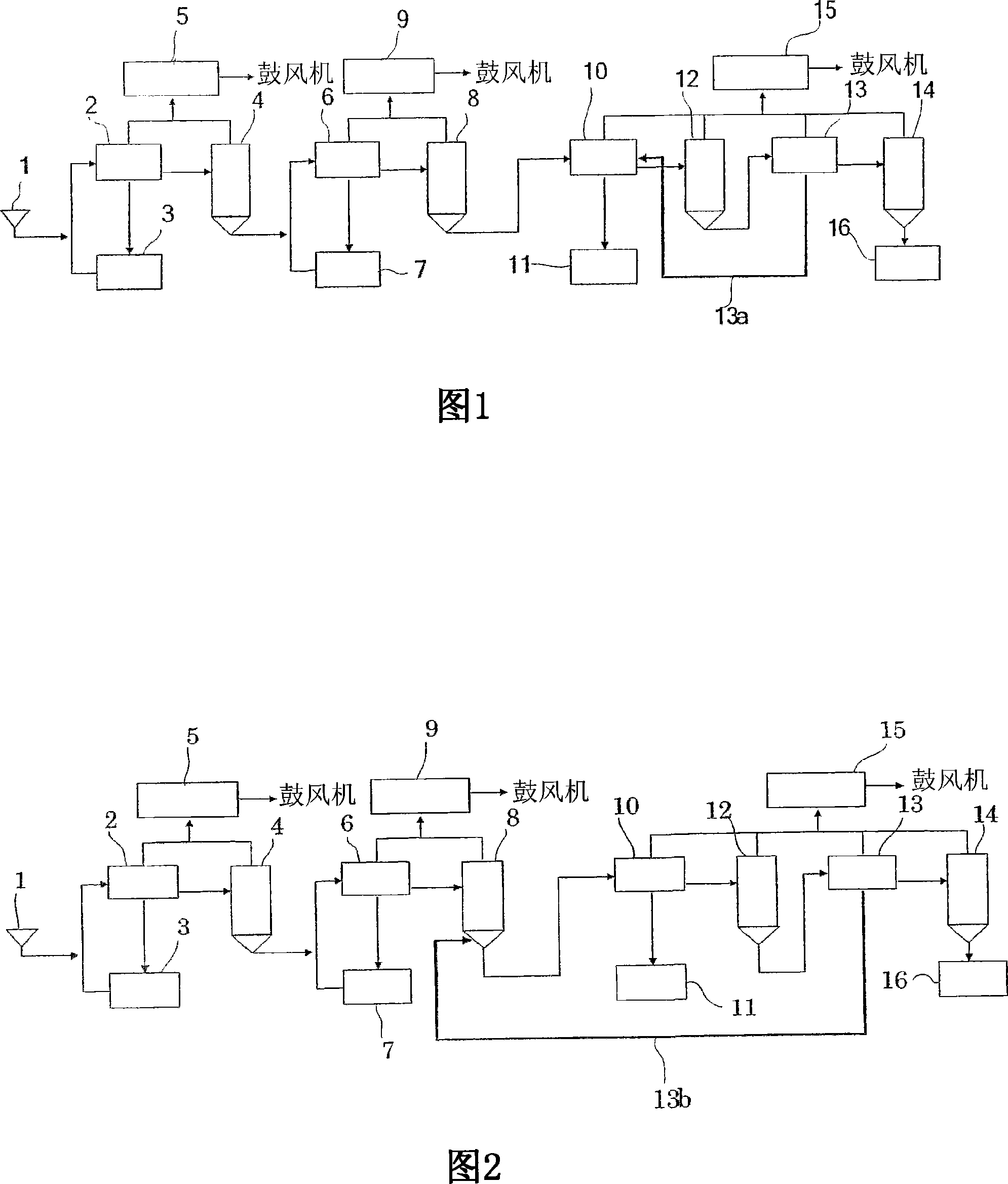

[0156] [114] Grinding and grading the toner raw material according to the process flow of the grinding and grading steps shown in FIG. 2 . In the flow shown in FIG. 2, any powdery particles and other particles are returned from the fourth classifier 13 in the classifying step to the second cyclone unit 8 in the grinding step through the return pipe 13b. In the second cyclone unit 8, a two-stage cyclone is used.

[0157] [115] According to the flow chart of the milling and classifying step shown in Figure 2, the particles were milled and classified for 5 hours, and the particle size and particle size distribution ...

Embodiment 2

[0167] [122] Grinding and grading the same toner raw material as in Example 1 to produce toner according to the flow of grinding and grading steps shown in FIG. 2 is as follows:

[0168] [123] In Example 2, the amount of particles returned to the second cyclone unit 8 by the particles is adjusted to a constant value in the range of 15% to 35% of the total volume of the second cyclone unit, and then the particles are ground and classification for 5 hours, and the particle size and particle size distribution of the particles were measured every 30 minutes in the same manner as in Example 1. The toner had a number-average particle diameter of 7.2 μm, a mass-average particle diameter of 9.0 μm, a content of powdery particles having a particle diameter of 4.0 μm or less of 24.0 number-average % (standard deviation σ=2.0), and a yield of 88.0%.

[0169] [124] Alternatively, the amount of particles returned to the second cyclone unit 8 is adjusted to a constant value in the range of...

Embodiment 3

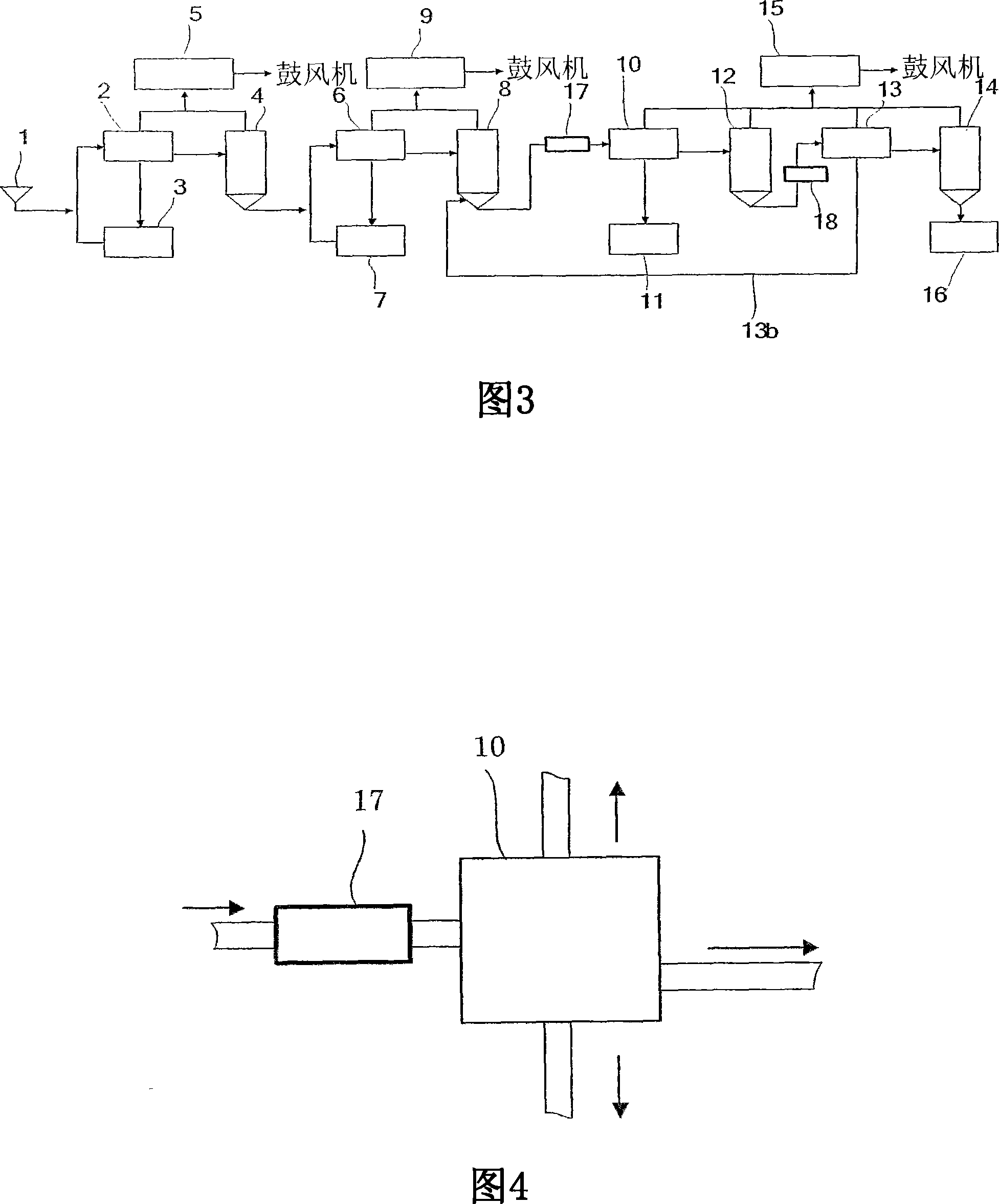

[0172] [126] Grinding and grading the same toner raw material as in Example 1 to produce toner according to the flow of grinding and grading steps shown in FIG. 3 is as follows:

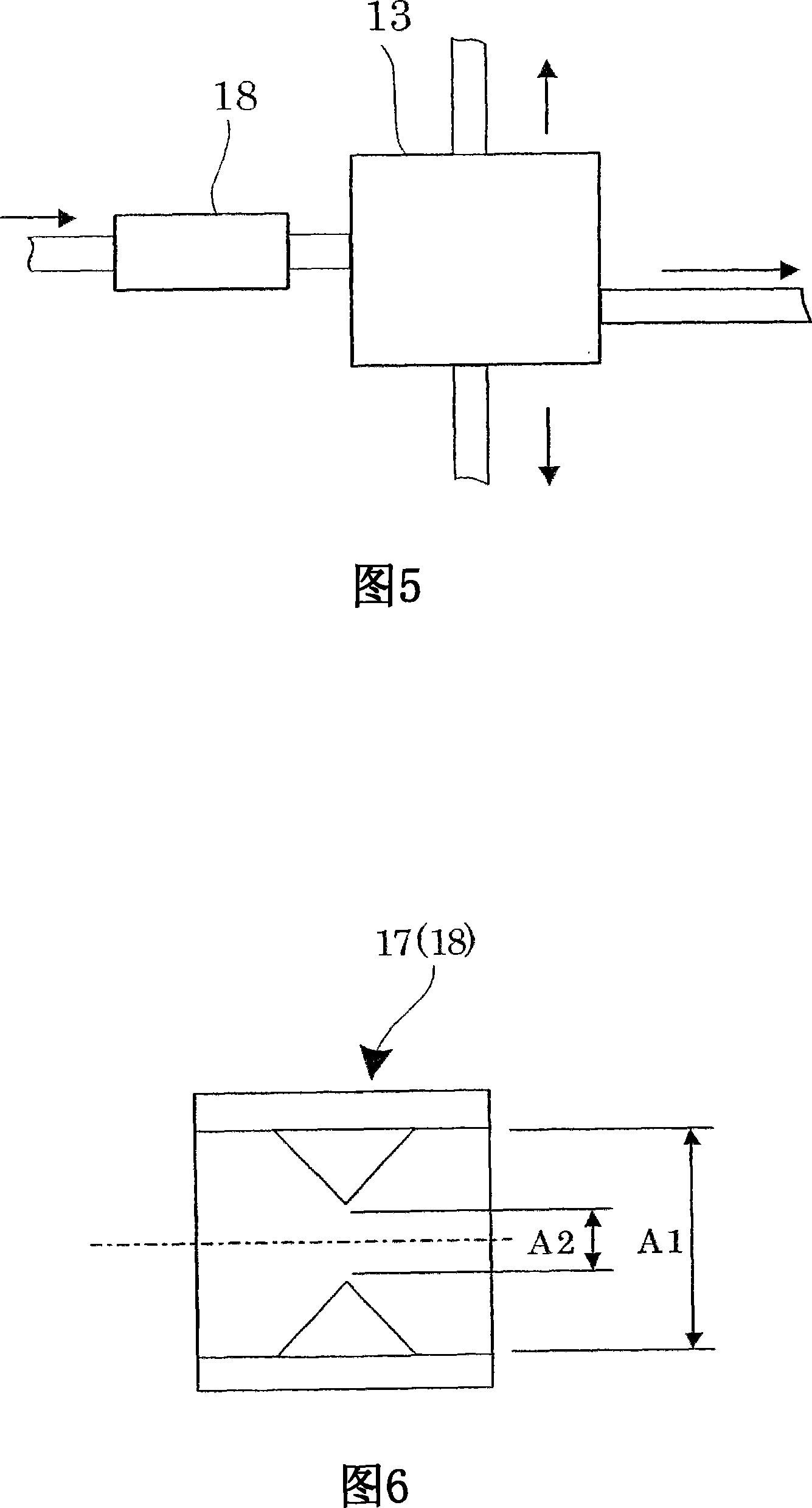

[0173] [127] The flow of the grinding and classifying step shown in FIG. 3 is the same as the flow of the grinding and classifying step shown in FIG. 2, except that the constriction 17 shown in FIG. The particle introduction pipe of the third classifier 10, and the constricted portion 18 shown in FIG. 6 is arranged in the particle introduction pipe of the fourth classifier 13 shown in FIG.

[0174] [128] The cross-section A2 of the constricted part is set at a fixed value ranging from 1×(A1 / 20) to 10×(A1 / 20), and then the particles are ground and classified for 5 hours, and in the same manner as in Example 1 The particle size and particle size distribution of the particles were measured every 30 minutes in the same way. The toner had a number-average particle diameter of 7.4 μm, a mass-average parti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com