Buffering body capable of completely flattening and combination thereof

A technology of a buffer body and a main body is applied in the field of buffer bodies, which can solve the problems of not being able to optimally utilize container space and wasting space, and achieve the effects of saving transportation costs and facilitating assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The aforementioned and other technical contents, features and functions of the present invention will be clearly presented in the following detailed description of two preferred embodiments with reference to the drawings.

[0064] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same reference numerals.

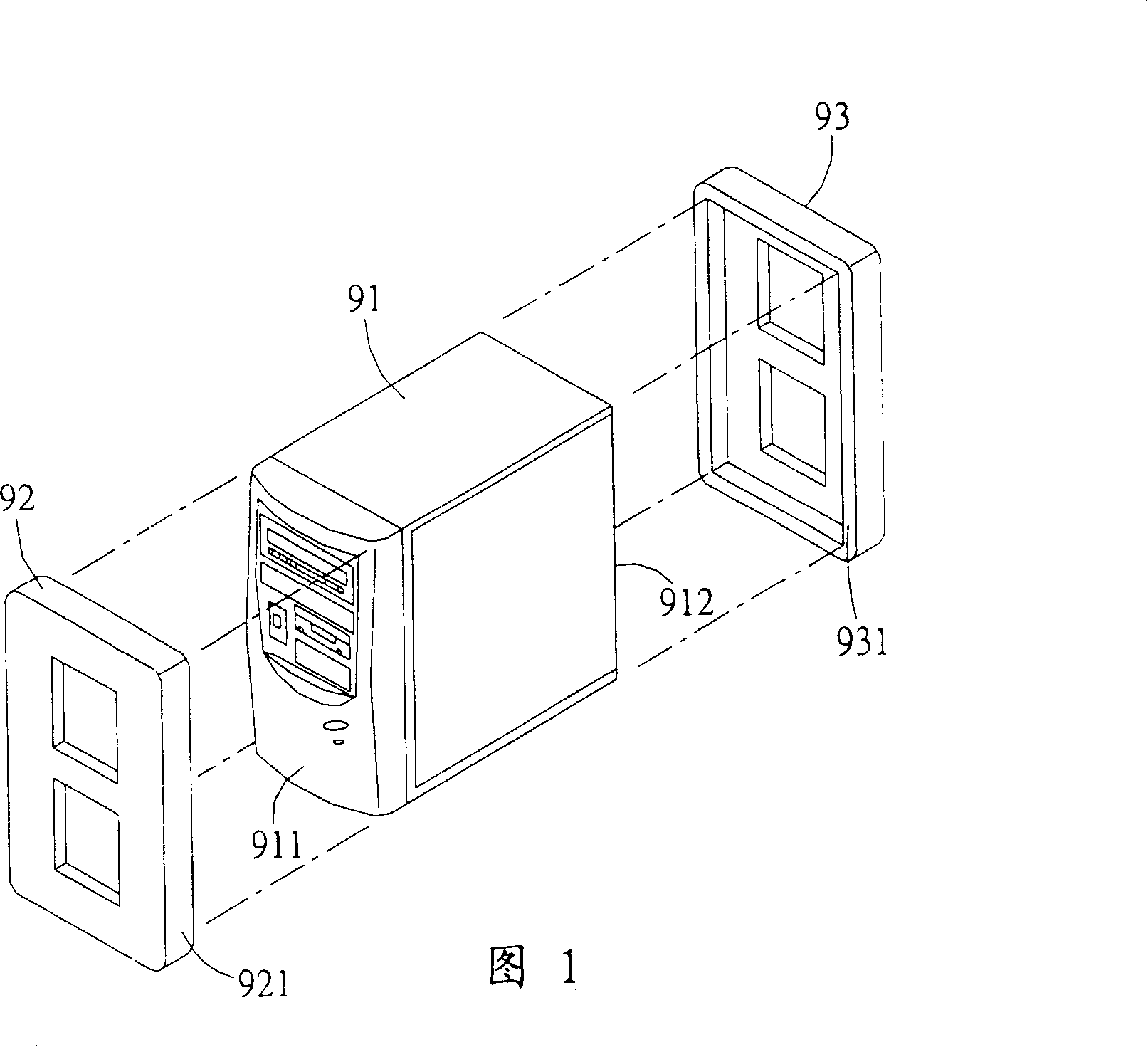

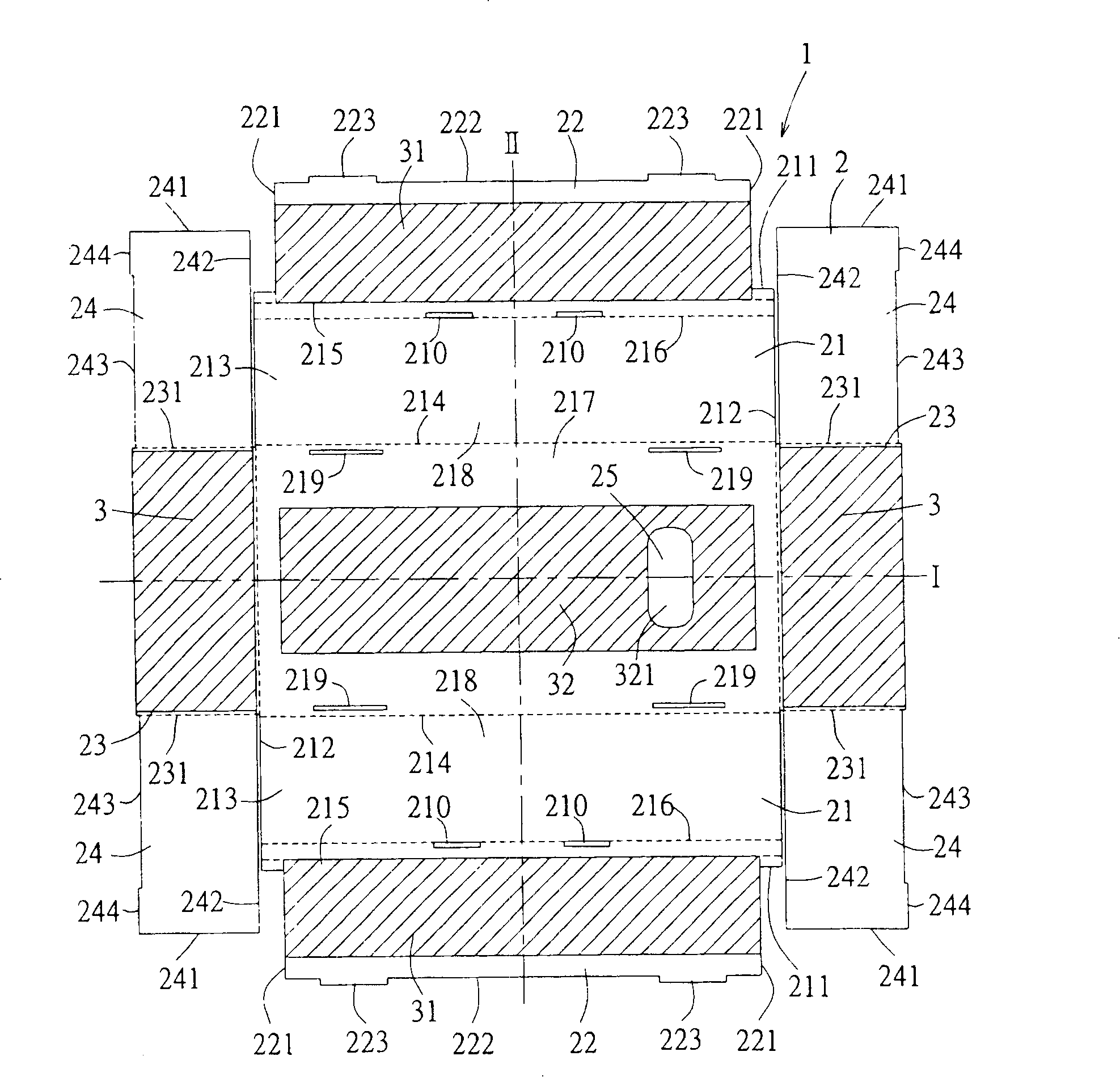

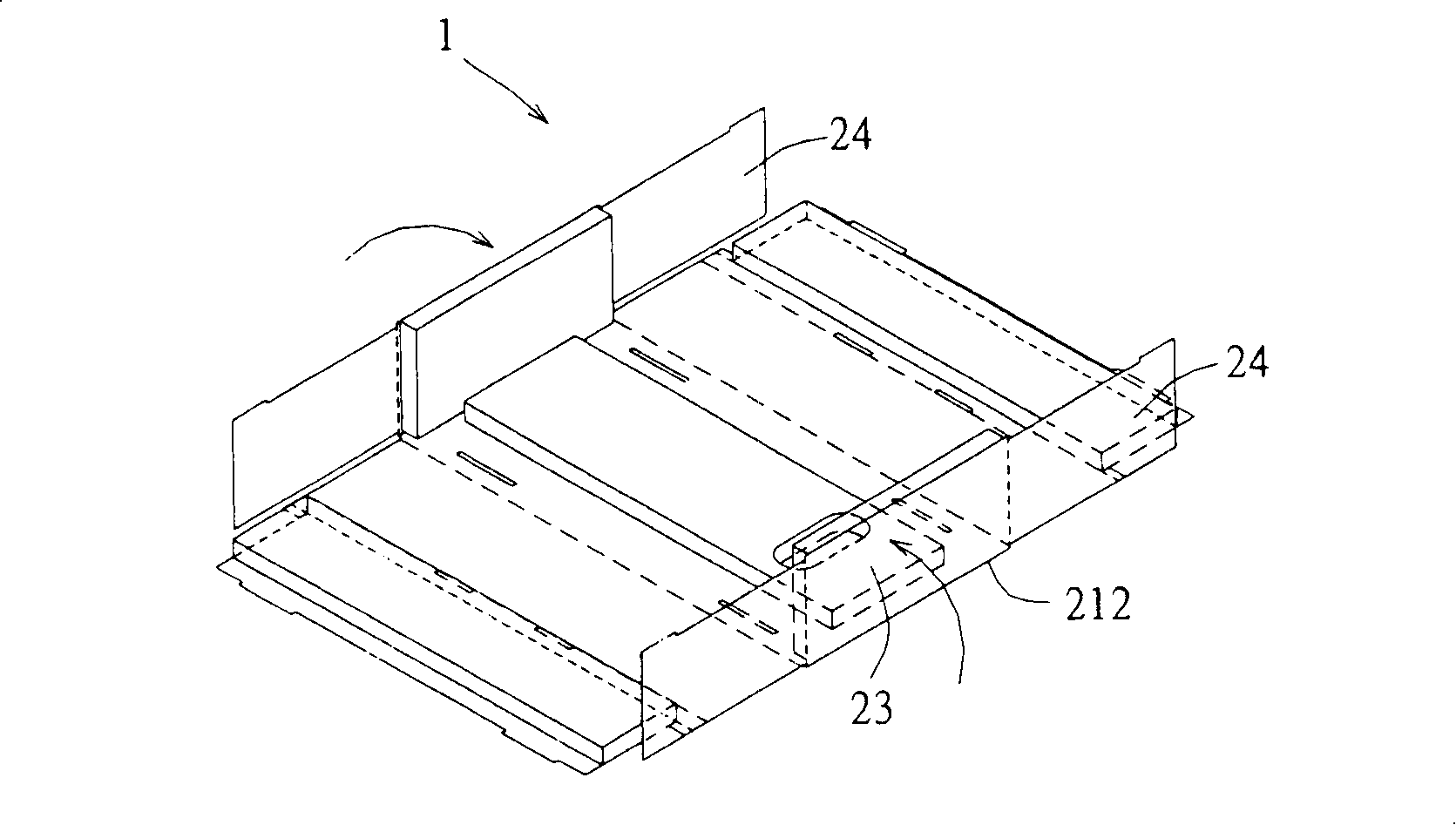

[0065] refer to figure 2 , the first preferred embodiment of the fully flattenable cushioning body of the present invention is suitable for packaging a computer case. The buffer body 1 includes a cardboard 2 and a plurality of soft boards 3 made of Styrofoam on the cardboard 2 .

[0066] In the unfolded state, the cardboard 2 includes a main body portion 21 , two first extension portions 22 , two second extension portions 23 and four wing portions 24 . The main body 21 is substantially rectangular and has a set of parallel first sides 211 , a set of parallel second sides 212...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com