Assembled corrugated board coffin

A corrugated, assembled technology, applied in the field of assembled corrugated coffins, can solve the problems of discarding, unable to restore to the unfolded state, unloading hooks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

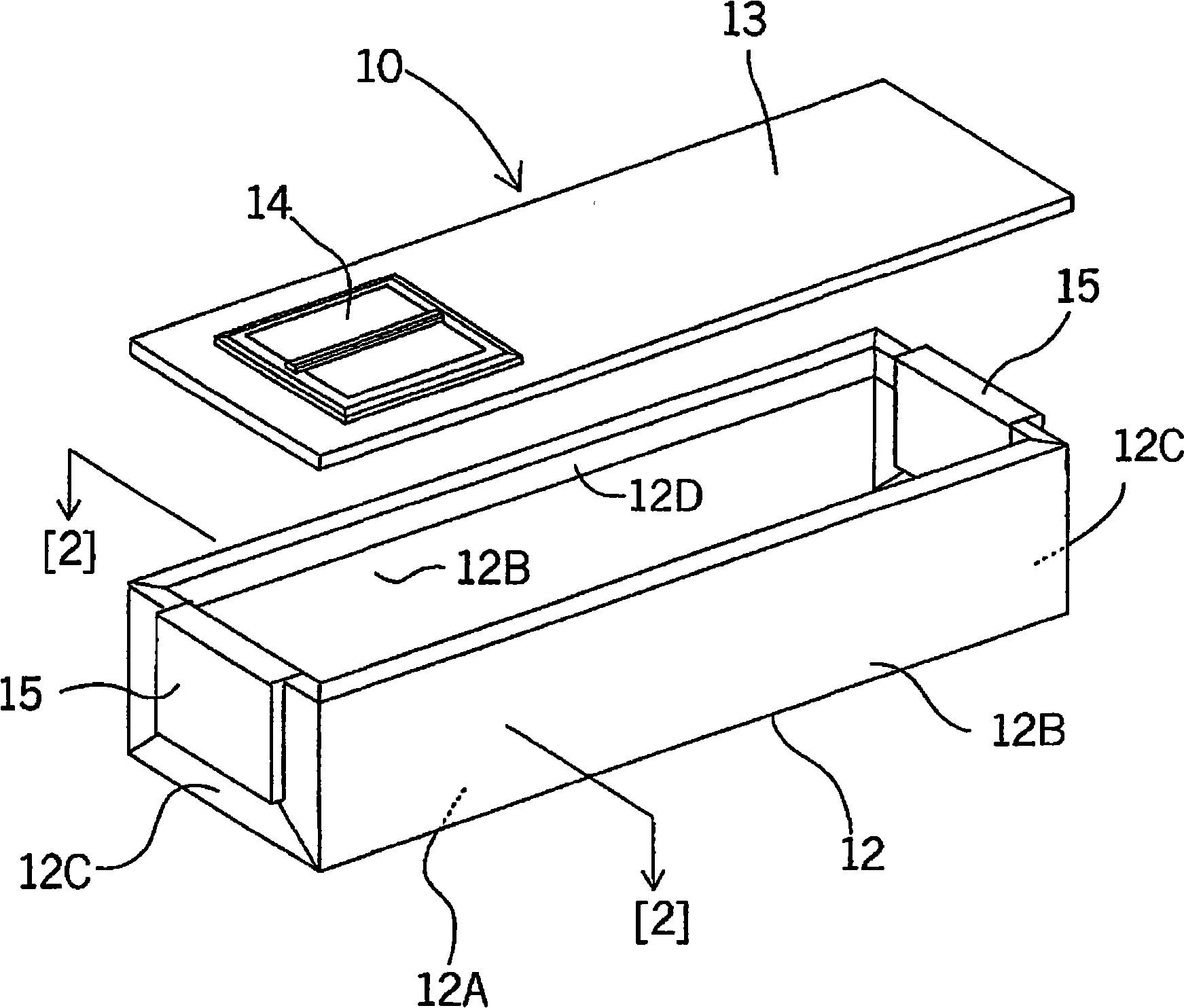

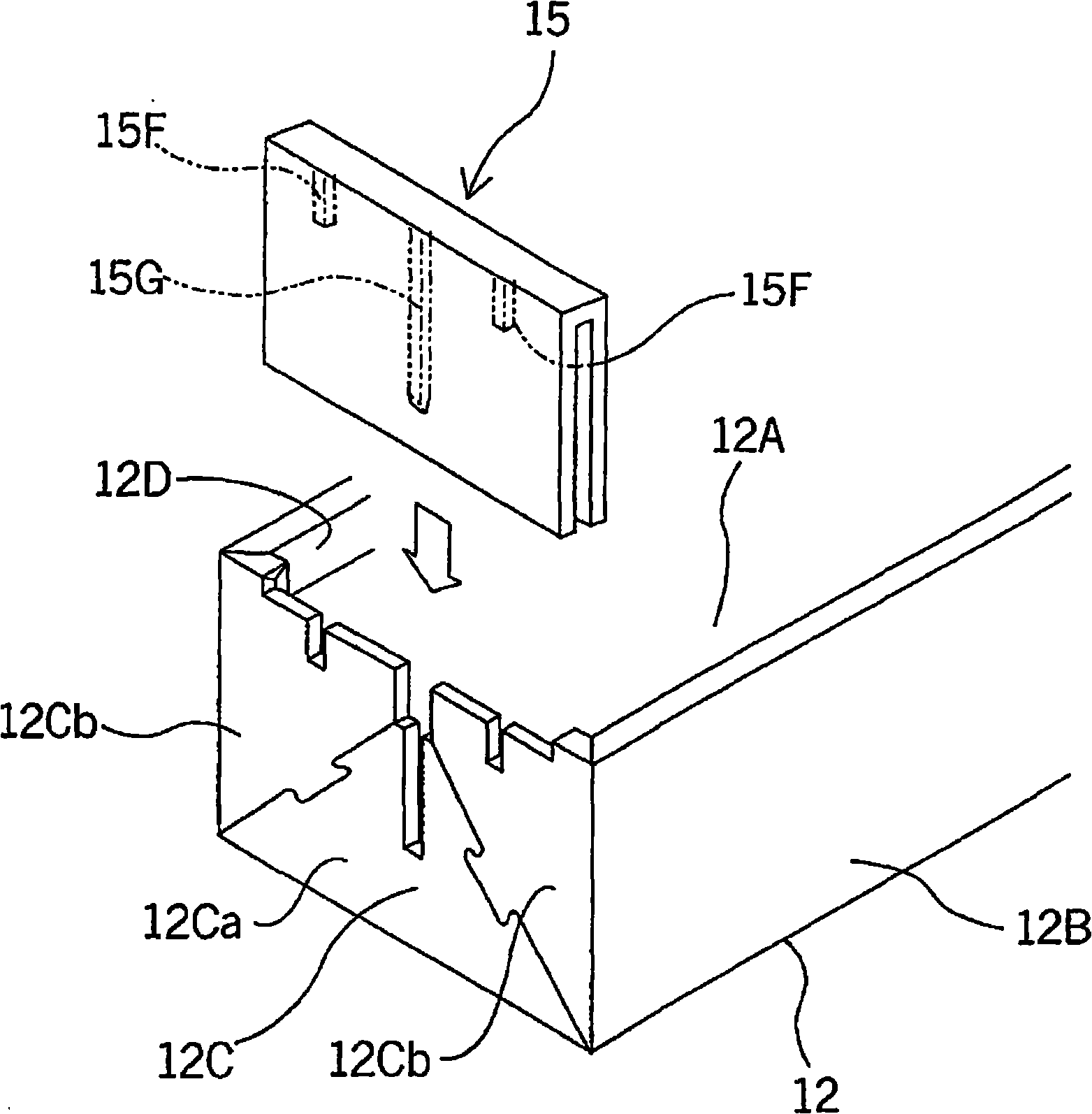

[0087] Such as figure 1 As shown, a corrugated coffin 10 includes a coffin body 12 and a lid 13 . The lid 13 is placed over the coffin body 12 . A window frame 14 is provided at a position close to the side of the cover 13 . Double doors are installed on the window frame 14, and by opening these doors, the inside of the coffin can be observed. The dimensions of the corrugated cardboard coffin 10 are, for example, about 170-200 cm in length, about 50-70 cm in width, and about 40-50 cm in height including the coffin main body 12 and lid 13 .

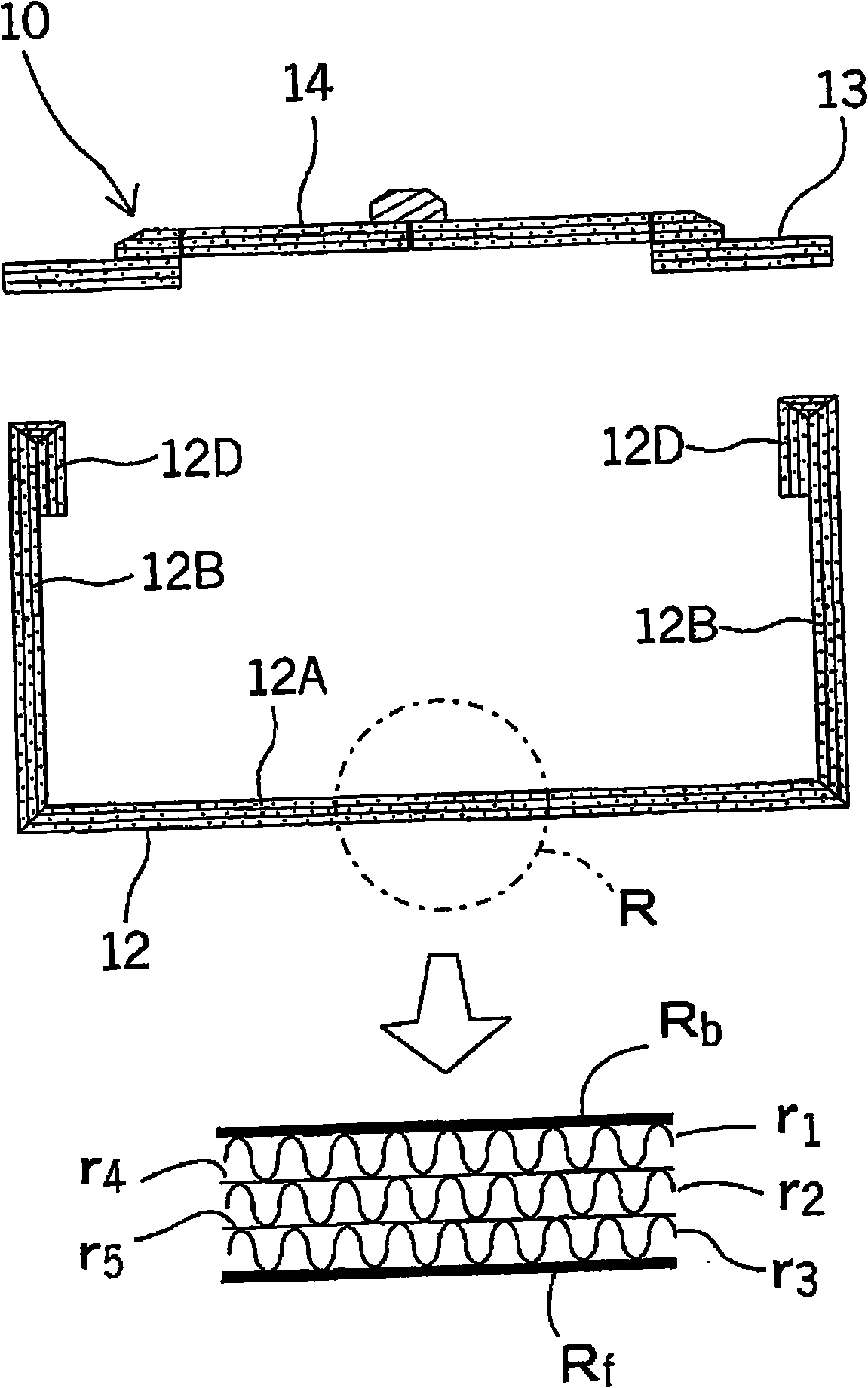

[0088] The coffin main body 12 and the lid 13 are formed of reinforced corrugated cardboard. As the reinforced corrugated cardboard, for example, a three-layer reinforced corrugated cardboard material having a thickness of about 10 to 20 mm (for example, a product made by TRAIUOL CO., LTD.) is used. This corrugated cardboard is figure 2 As shown in the enlarged view of the R part, it is formed by laminating three layers of corrugate...

no. 2 approach

[0115] Next, a second embodiment of the present invention is shown in Figure 10 to Figure 12 . The assembled corrugated cardboard coffin of the second embodiment employs an end plate 22C and a lock member 25 instead of the end plate 12C and the lock member 15 of the first embodiment.

[0116] Such as Figure 10 As shown, the end plate 22C is formed by an equilateral trapezoidal bottom end portion 22Ca and side end portions 22Cb, 22Cb adjacent to the left and right inclined sides. A rectangular space M is opened in the portion surrounded by these end portions. Further, vertical rails 22D, 22D having a constant width are formed on the insides of the front ends of the side end portions 22Cb, 22Cb, which are continuous in the vertical direction.

[0117] The lock member 25 includes a rectangular flat plate portion 25A and hook portions 25B provided at both end portions thereof. A rectangular top plate 25D is fixed above the flat plate portion 25A and the hook portion 25B. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com