Micro-mechanical element capable of derivation

A micro-mechanical and component technology, applied in the field of deflectable micro-mechanical components, can solve the problems of spring nonlinear characteristics, insufficient stiffness, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

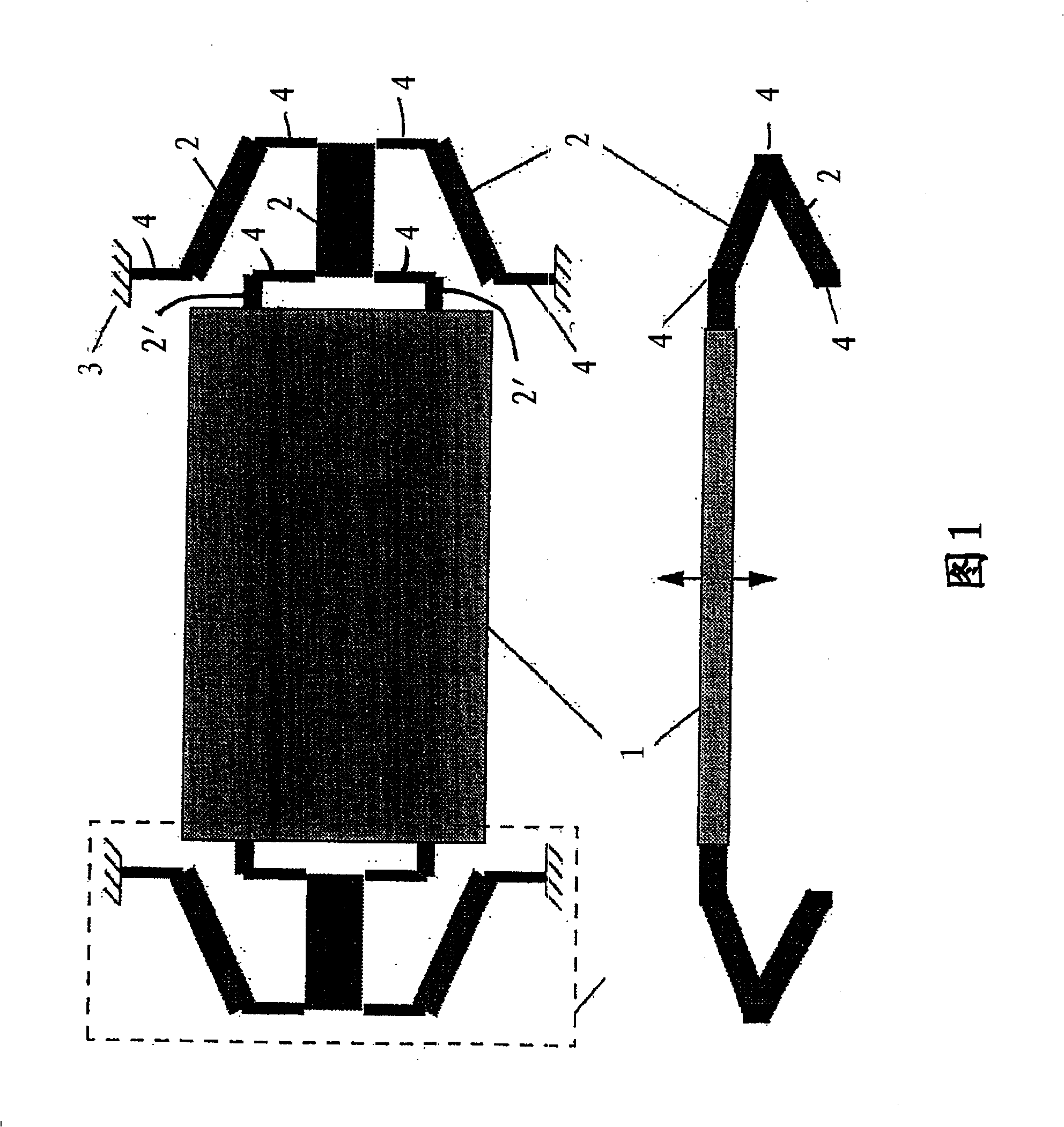

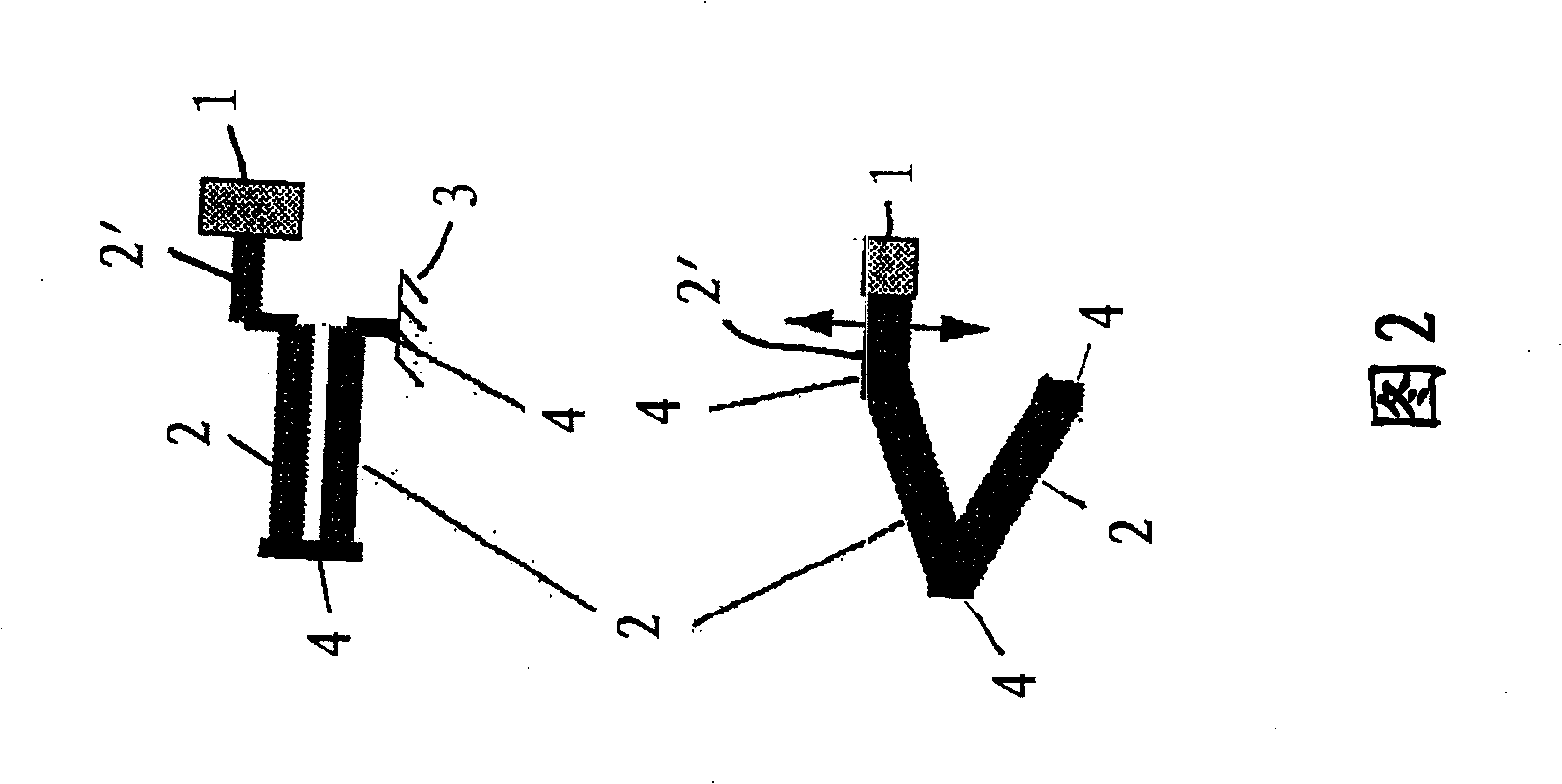

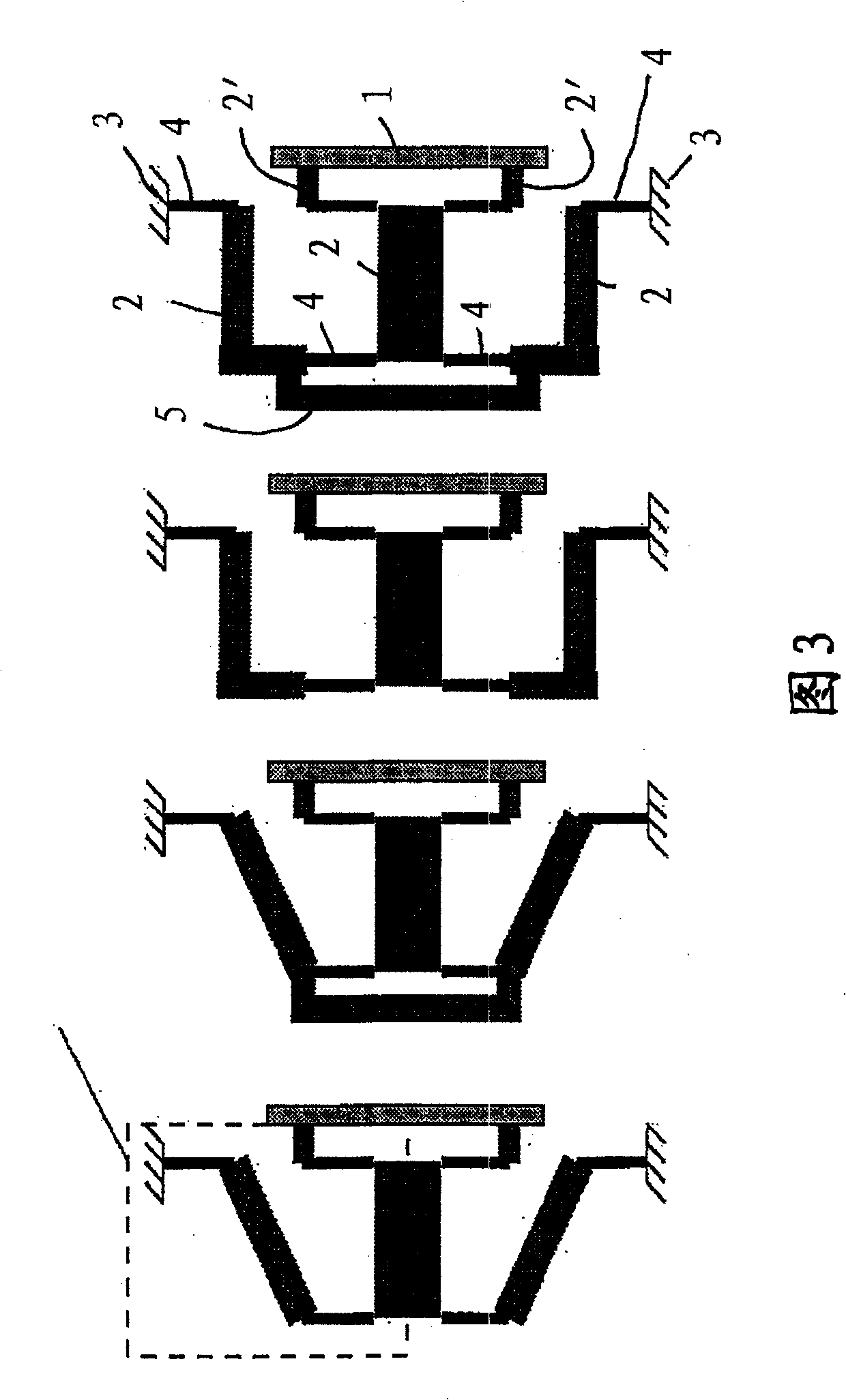

[0042] An exemplary embodiment of an element according to the invention is shown in two views in FIG. 1 . In the plan view shown at the top, it is clearly seen that the suspension of the micromechanical element 1 is formed with two spring systems arranged diametrically opposite at the micromechanical element 1 and joined to the micromechanical element 1 by means of a connecting rod 2'. mechanical element 1. On one side of the link 2, the link 2' is pivotally connected to the link 2 by means of a torsion spring element 4. At the other side of the connecting rod 2 two torsion spring elements 4 in turn connect the connecting rod 2 with two other corresponding connecting rods 2 in a pivotal connection. The latter so-called connecting rod 2 is inclined at an oblique angle relative to the axis of the torsion spring element 4 . At the other end of the connecting rods 2 there is again a torsion spring element 4 which is connected to the end faces of the connecting rods 2 on one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com