Epicyclic reduction gear with multiple modular stages

A technology of planetary reduction and reduction gears, applied in the direction of gear transmissions, belts/chains/gears, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

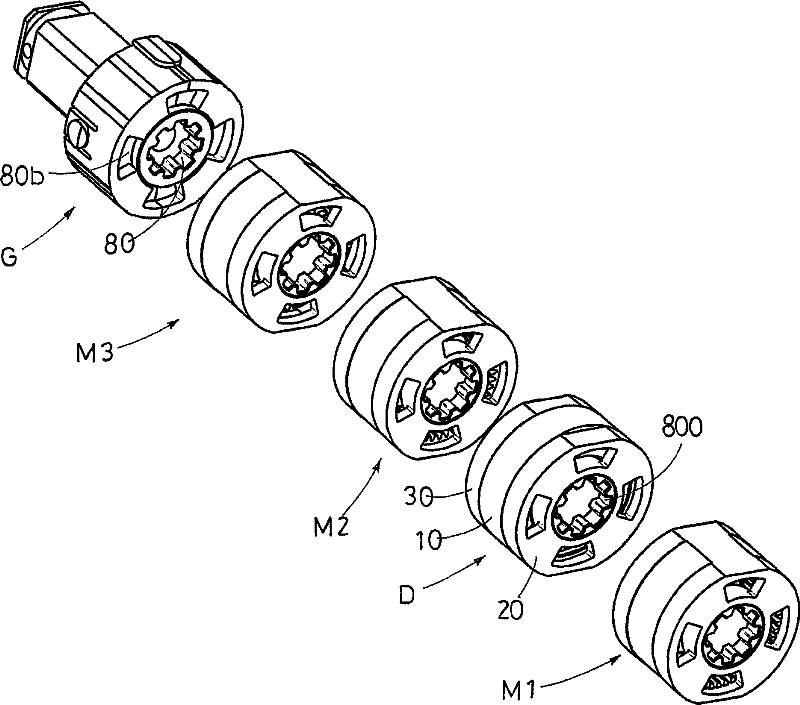

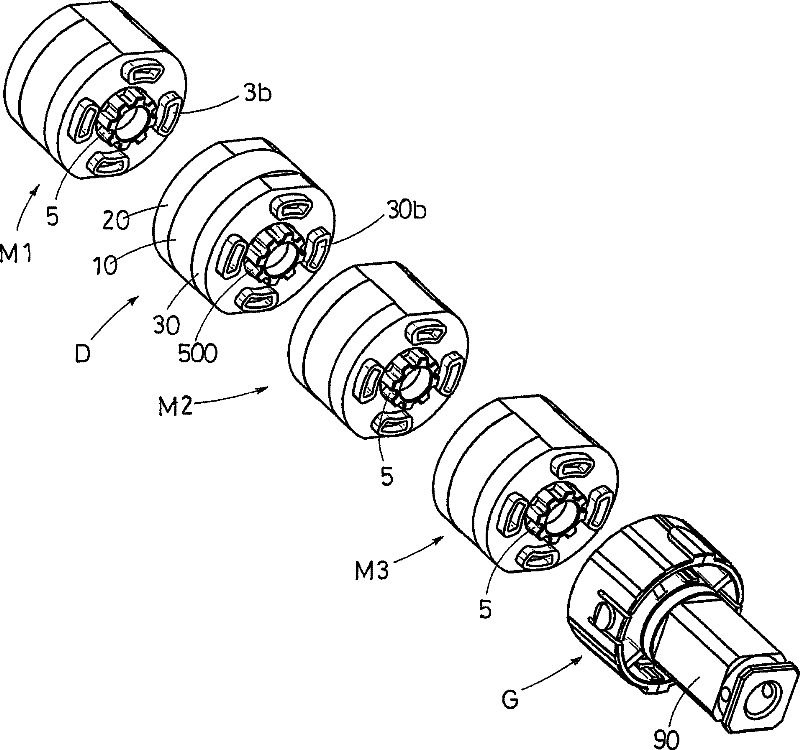

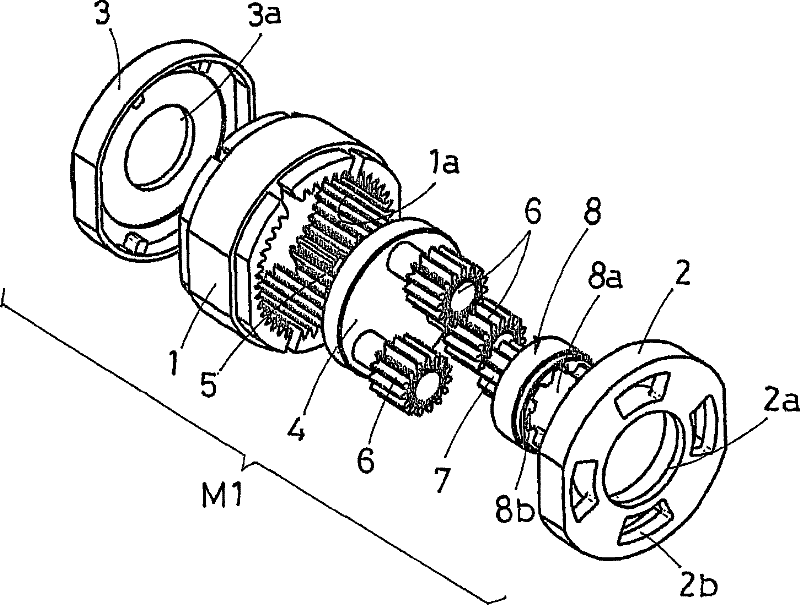

[0022] It must be noted that the accompanying figures show a planetary reduction gear formed by three combined stages, each stage having an "inner" mesh at the input and an "outer" mesh at the output. Obviously, it is also possible to equip the input side with the internal snap-in device and the output side with the external snap-in device.

[0023] refer to figure 1 with figure 2 , the planetary reduction gear R is formed by a gear train of three combined reduction stages M1, M2, M3, which are designed to be connected one after the other in any order.

[0024] M1 represents the first reduction stage, that is, the reduction stage toward the motor (not shown in the figure), and M3 represents the last reduction stage, that is, the reduction stage toward the winding roller of the roller blind (not shown in the figure). .

[0025] The reduction stages M1, M2, M3 have the same size and construction, while the gear ratio depends on the size of the gears they contain.

[0026] r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com