Gas compression quick-release system

A technology of release system and gas compression, applied in vehicle safety arrangement, pedestrian/occupant safety arrangement, transportation and packaging, etc., can solve the problems of non-reusable, increase production cost, reduce enterprise benefit, etc., achieve small response delay, Turn on fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

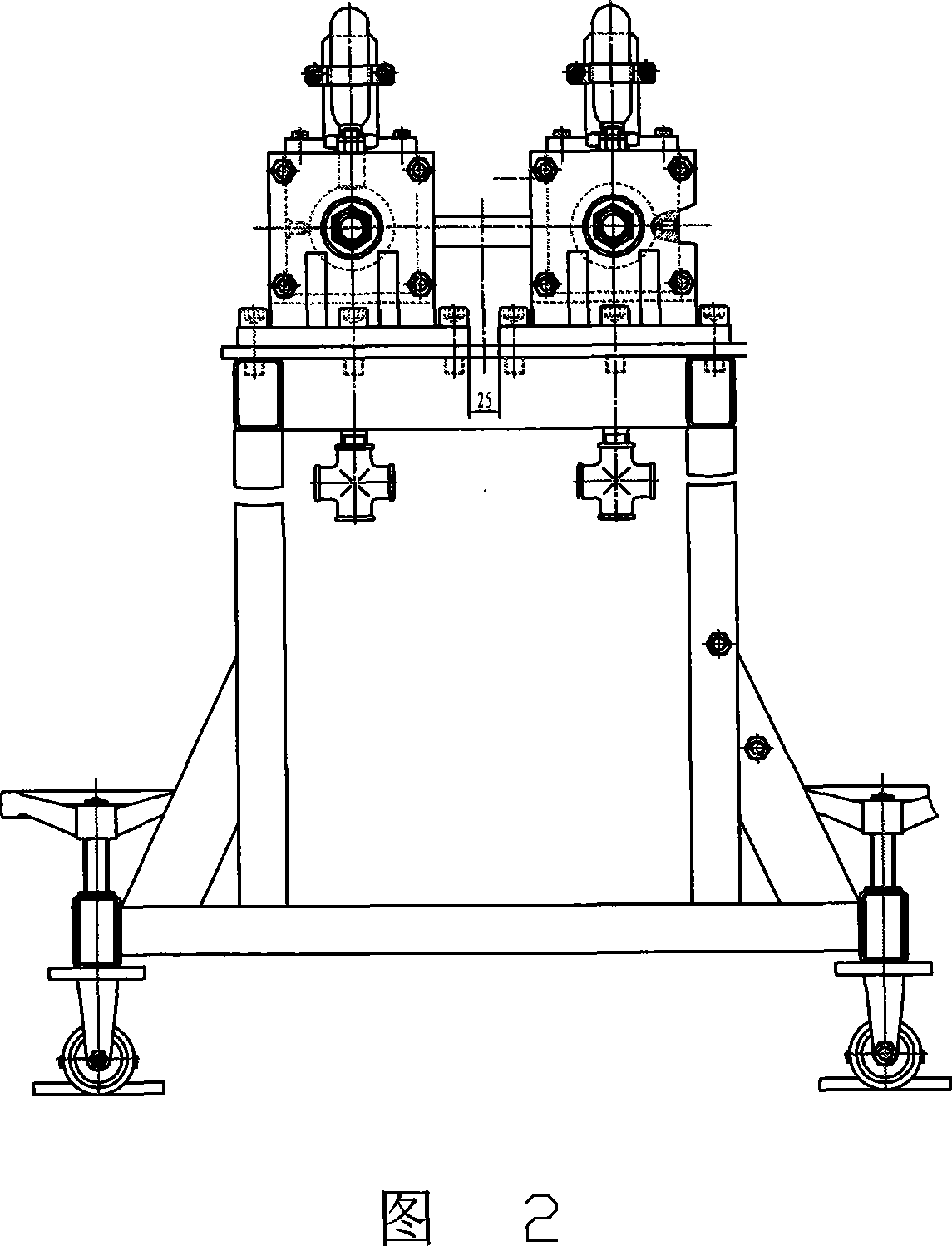

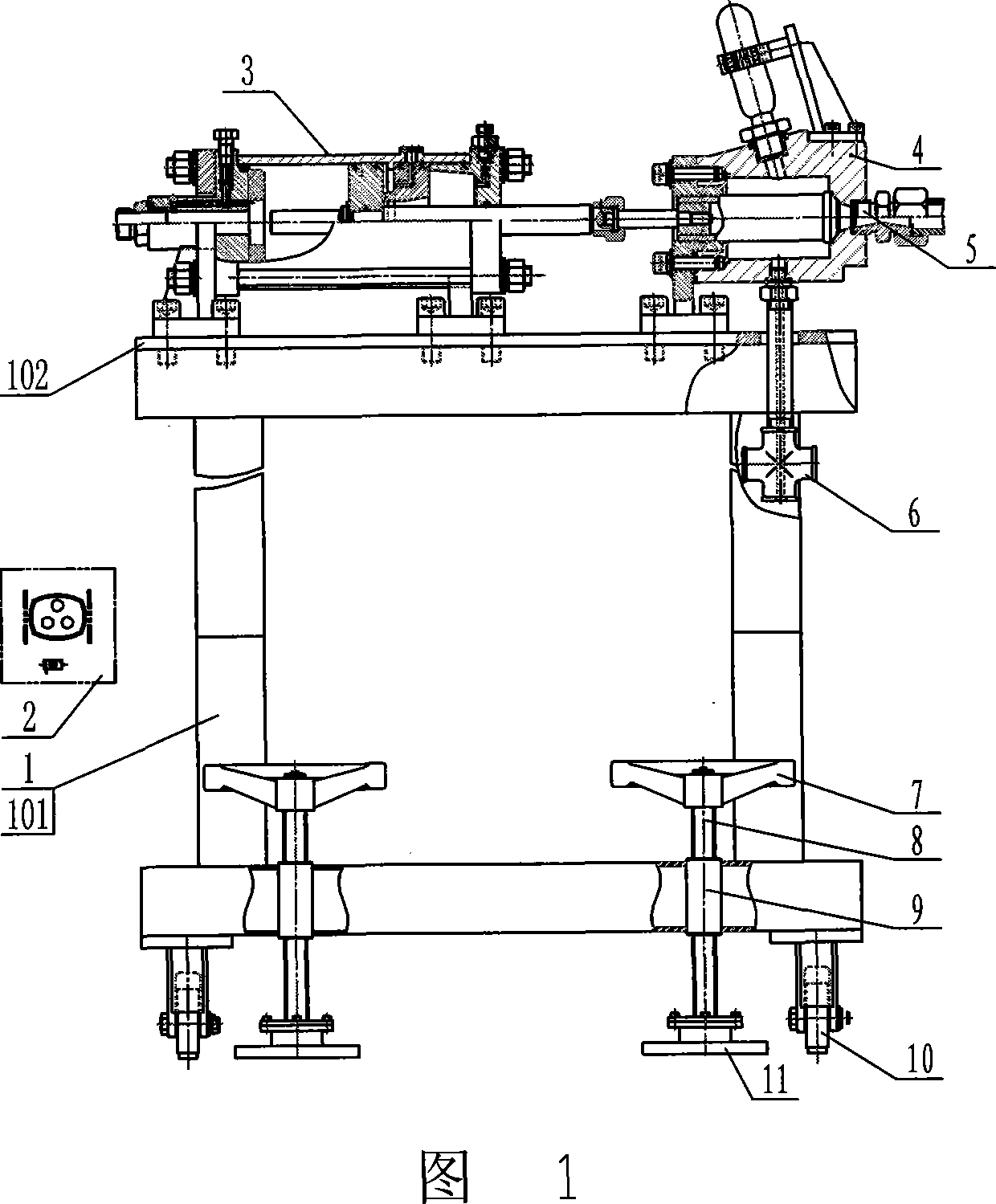

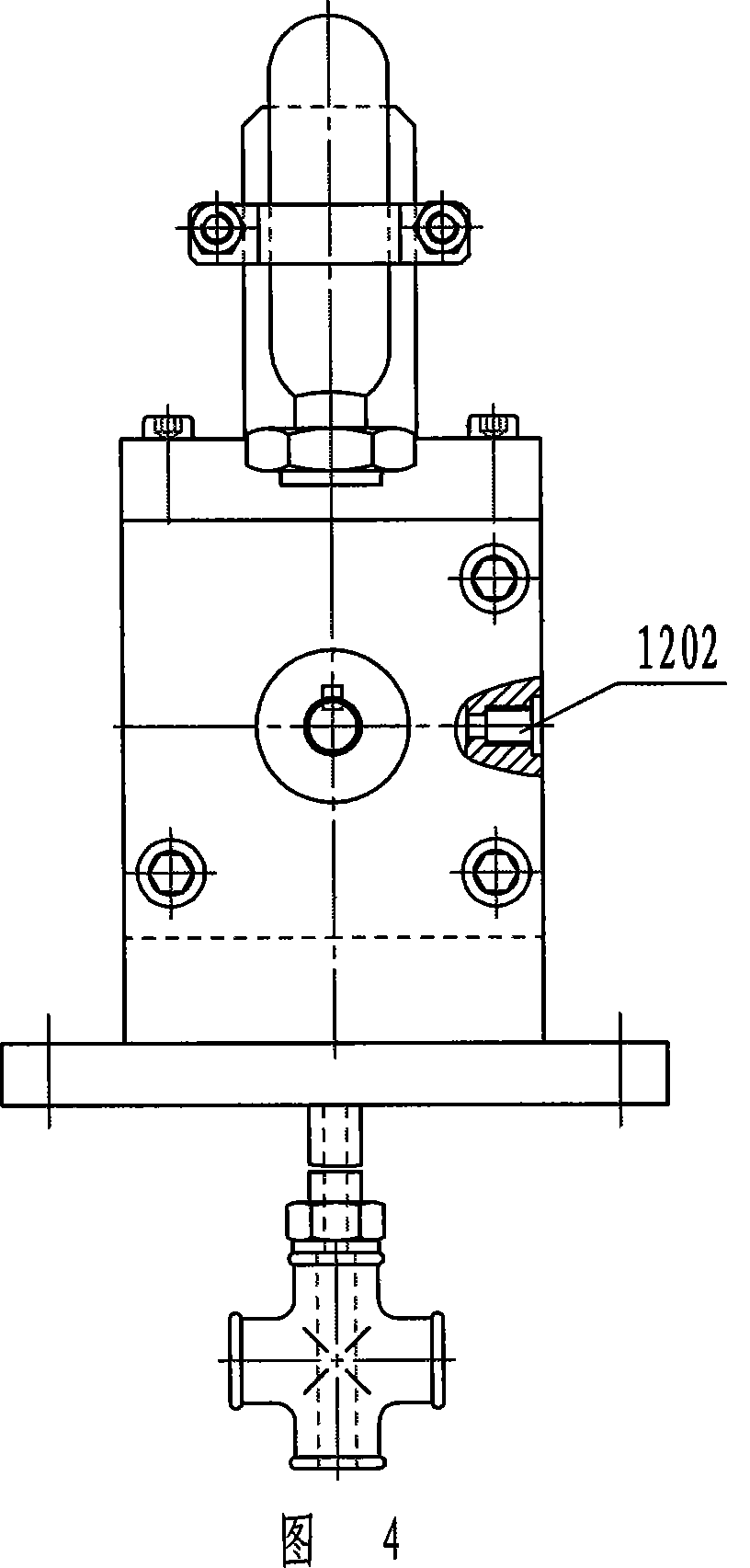

[0022] Such as Figure 1-Figure 7As shown, the present invention has a frame 1, and the frame 1 is composed of a bracket 101 welded by square tubes and a cover plate 102 fixedly laid on the upper end of the bracket 101, and four corners of the bottom of the bracket 101 are respectively installed with The traveling wheel 10 is symmetrically provided with four lifting support devices on the bottom beam of the support 101 . This lifting supporting device is to be welded on the bottom crossbeam of support 101 by the lifting nut 9, be located at the lifting screw 8 on the lifting nut 9, be fixed on the hand wheel 7 on the lifting screw 8 upper end and be fixed on the lifting screw 8 lower end The support plate 11 constitutes. On the cover plate 102, the inflator 4 and the opening cylinder 3 are fixed with each other, and the inflator 4 includes a main air tank 12, and the upper and lower sides of the main air tank 12 are connected with the main air tank 12 by threads respectively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com