Device for measuring material friction action in multiatmosphere and vacuum environment

A technology of vacuum environment and gas storage device, which is applied in measuring devices, analyzing materials, adopting mechanical devices, etc., can solve the problems that the friction test device cannot meet the research requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

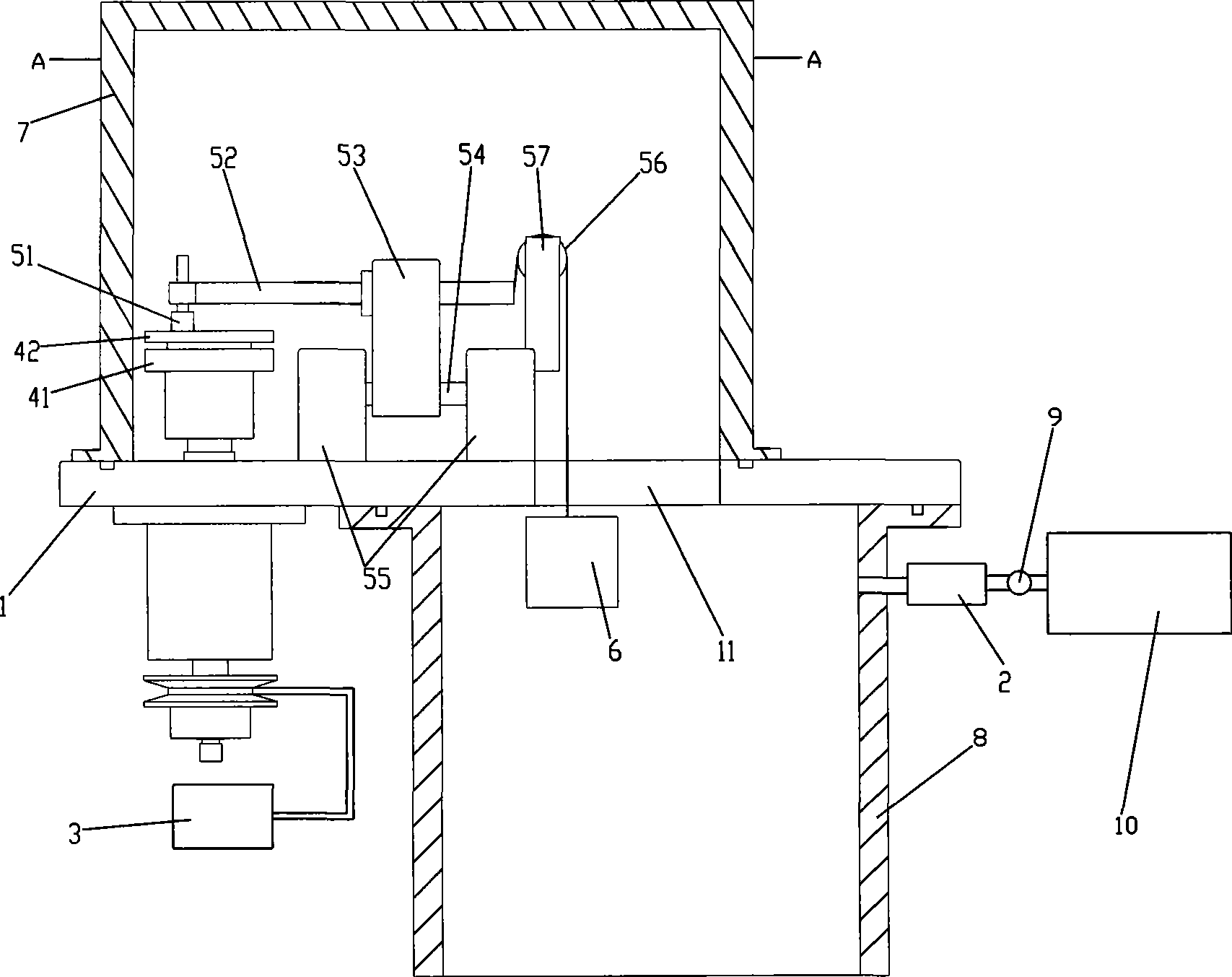

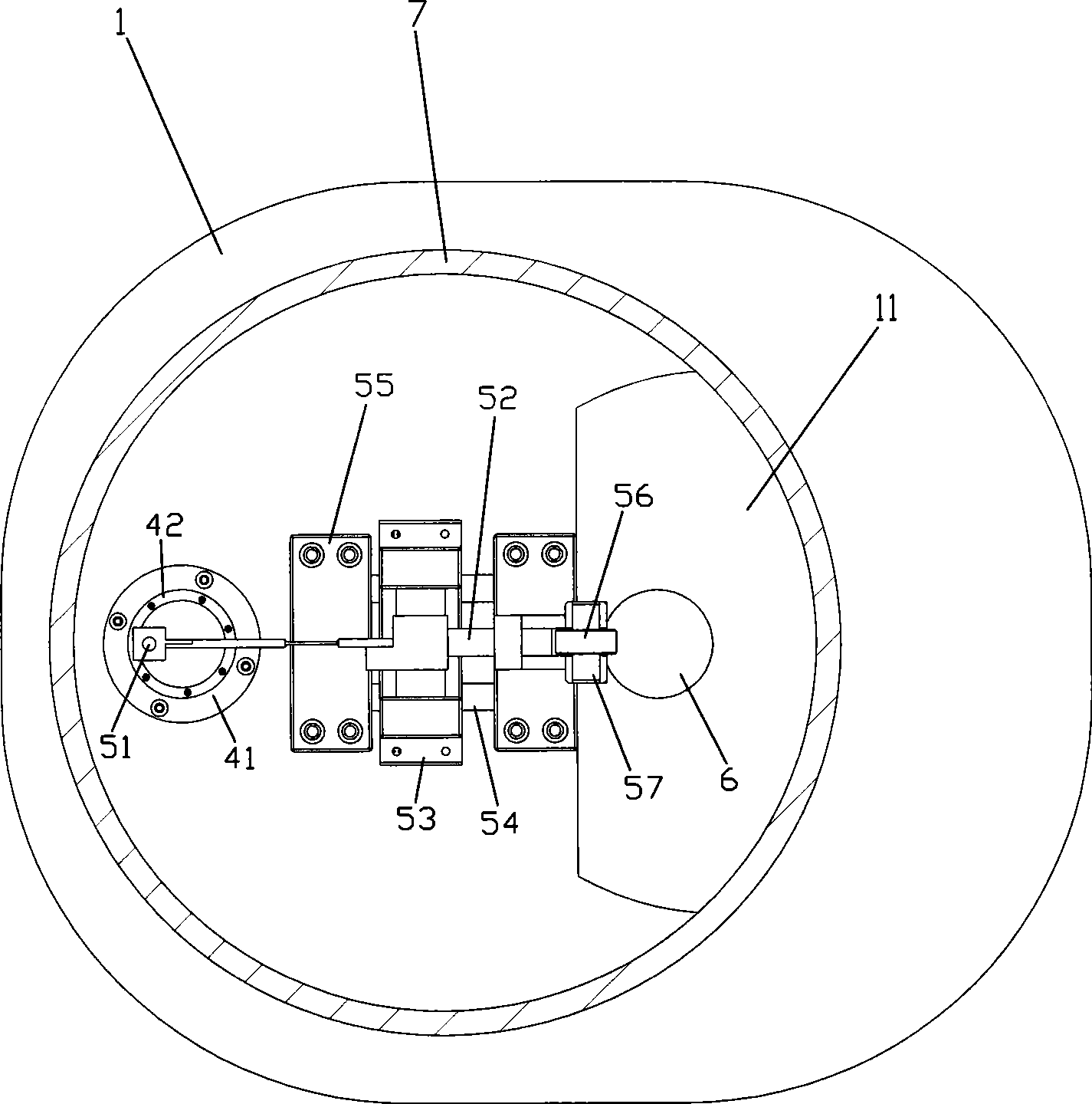

[0016] Such as figure 1 with 2 As shown, the device for measuring the frictional behavior of materials in a vacuum environment of the present invention includes a base 1, a motor 3, a sample clamping mechanism, an indenter control mechanism and a vacuum cover 7, and the sample clamping mechanism includes a sample table 41, a sample pressing cover 42 and The vertical rotary shaft, the sample table 41 is connected with the base 1 through the vertical rotary shaft, the vertical rotary shaft passes through the base 1, and is connected with the motor 3 through a belt, the sample table 41 and the sample gland 42 are both disc structures, and the sample The surface of the platform 41 is parallel to the base surface, and the sample pressing cover 42 is pressed and fixed on the sample platform 41, wherein the sample pressing cover 42 is an annular disk, and the area of the annular opening is smaller than the upper surface area of the sample. The cover 42 and the sample stage 41 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com