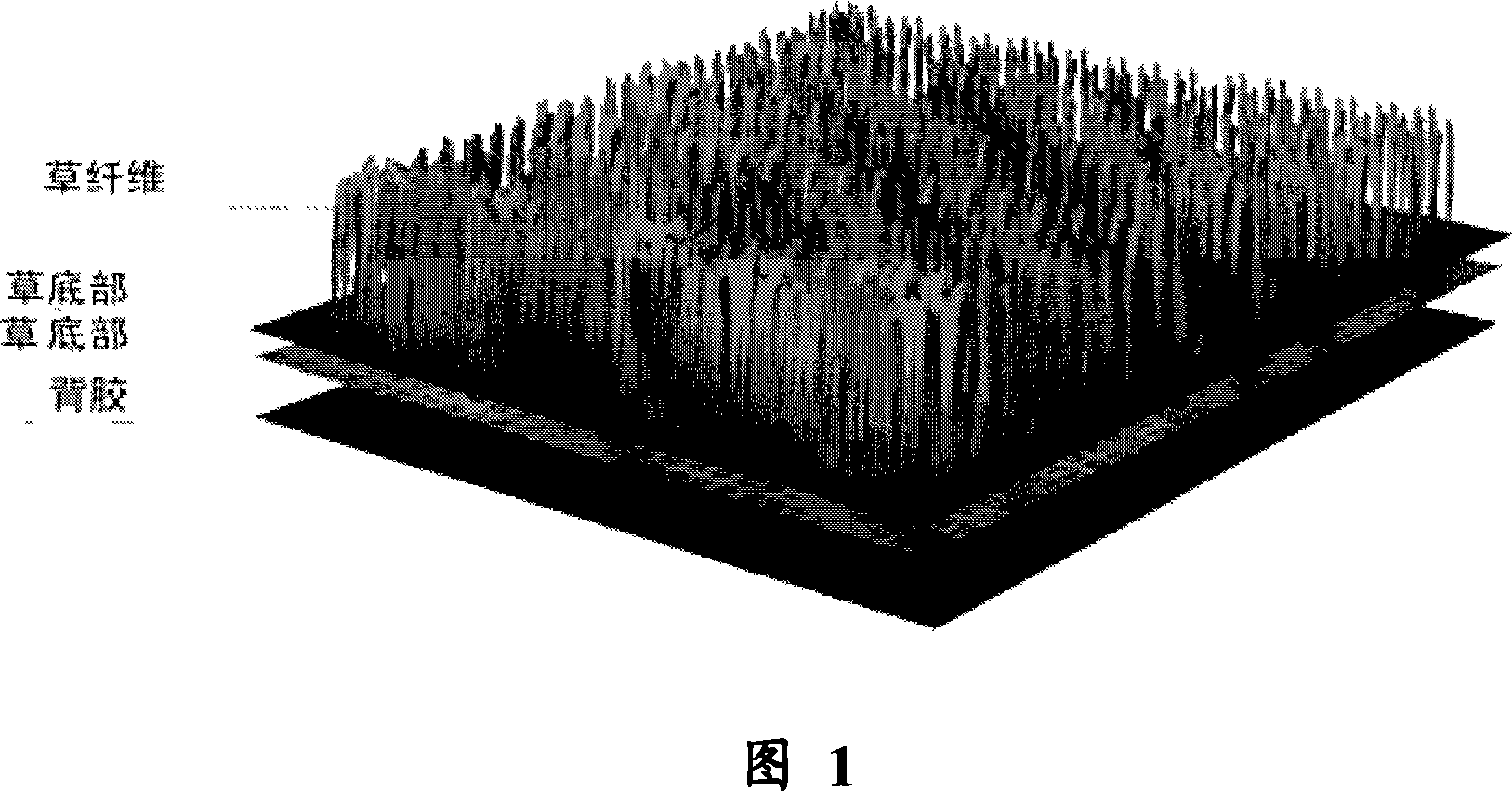

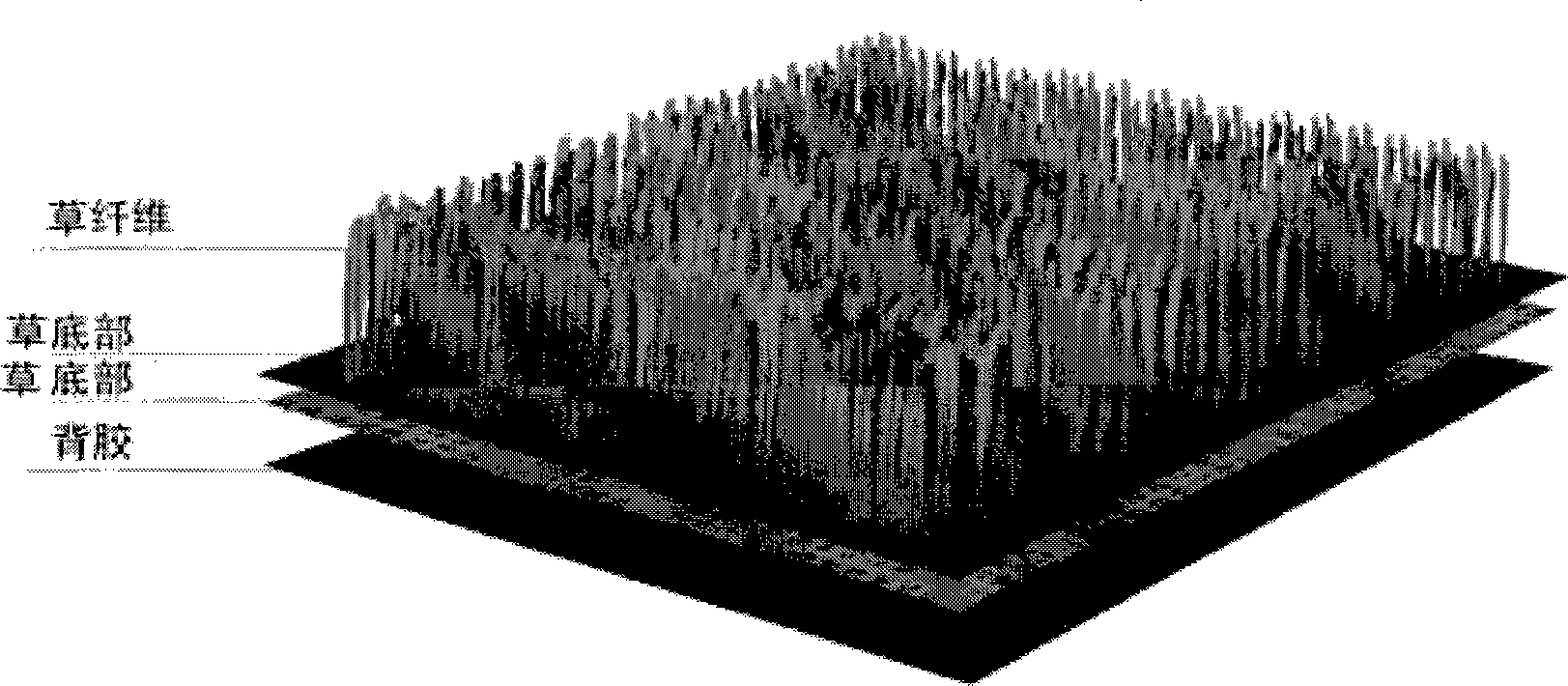

Novel synthetic turf and method for producing the same

A technology of artificial turf and grass fiber, applied in the direction of roads, pavements, roads, etc., can solve the problems of ununiform recycling, artificial turf cannot be uniformly recycled, and materials are incompatible with each other.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 100 parts of EVA (ethylene-vinyl acetate copolymer resin) (parts by weight, the same below), 30 parts of talcum powder, 10 parts of rosin, 10 parts of paraffin wax, 10 parts of epoxidized soybean oil, 10101 parts of antioxidant.

Embodiment 2

[0031] 100 parts of EVA (ethylene-vinyl acetate copolymer resin), 100 parts of heavy calcium carbonate, 50 parts of rosin, 50 parts of paraffin, 20 parts of epoxy soybean oil, and 10102 parts of antioxidant.

[0032] Before the back glue is used, the components of the back glue formula other than EVA are firstly stirred in a container (such as a high mixer) and granulated, and then set aside.

[0033] The manufacturing process of the artificial turf of the present invention includes preparing the above-mentioned back adhesive formula components into a film and bonding it to the assembled grass fiber and grass bottom (hereinafter referred to as "turf"). The embodiment of the specific manufacturing process is described as follows.

[0034] Manufacturing process implementation plan one

Embodiment approach 2

[0036]The components of the pretreated back adhesive formula except EVA are uniformly mixed with EVA to prepare a hot-melt film. The prepared hot-melt film is transported by the conveying roller and tightly attached to the back of the turf through the pressing shaft. Move the hot-melt film and turf towards the hot air box at the same speed, and at the same time, provide a suction box under the turf to suck air downward, and when the hot-melt film and turf pass through the hot air box, there is hot air in the hot air box (110 ℃~150℃) from top to bottom to blow the hot-melt film, so that the hot-melt film and the turf are bonded together.

[0037] Manufacturing process implementation plan three

[0038] Mix the components of the pretreated adhesive formula except EVA with EVA, and cast a hot melt film through an extruder and a casting die. The hot-melt film is directly attached to the back of the turf, and the two pass through the hot air box together. In the hot-air box, hot ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com