An artificial turf and a method thereof

A technology of artificial turf and grass fiber, used in textiles and papermaking, sports accessories, bundling of skis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

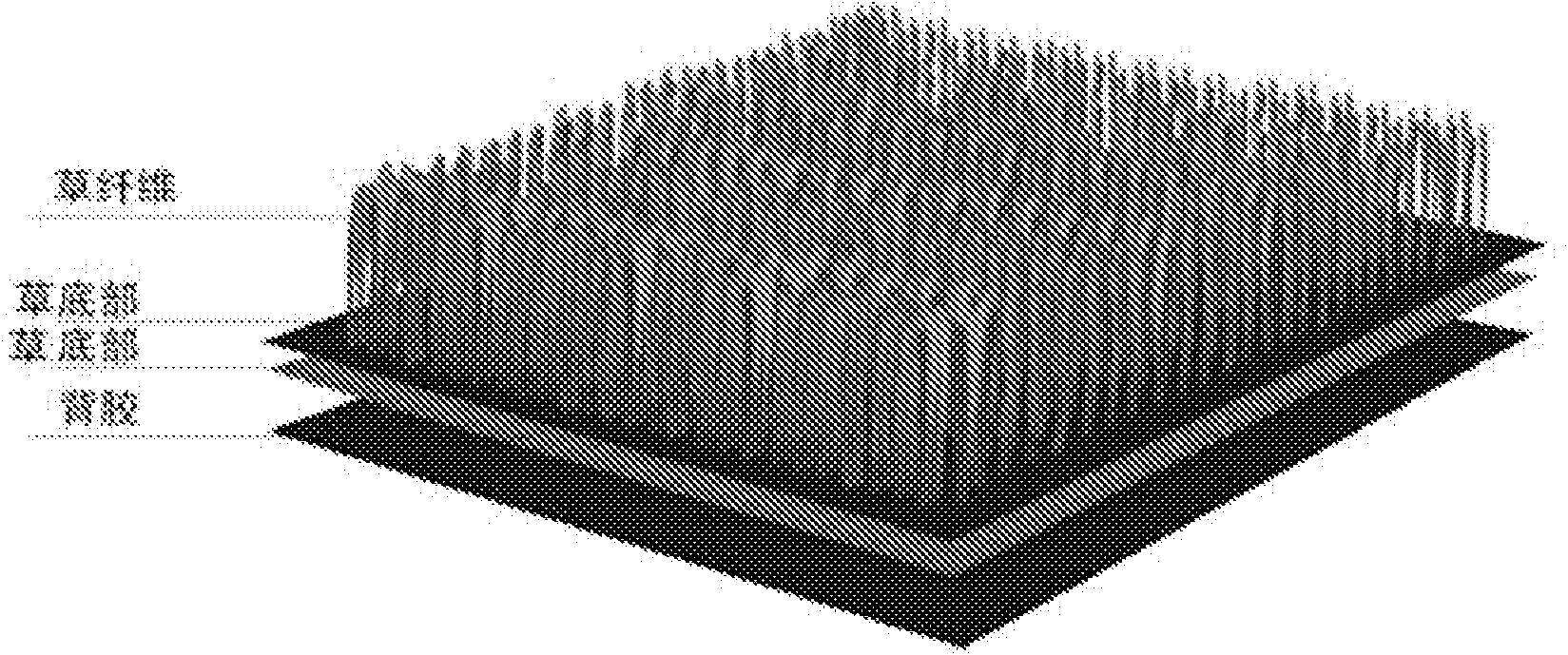

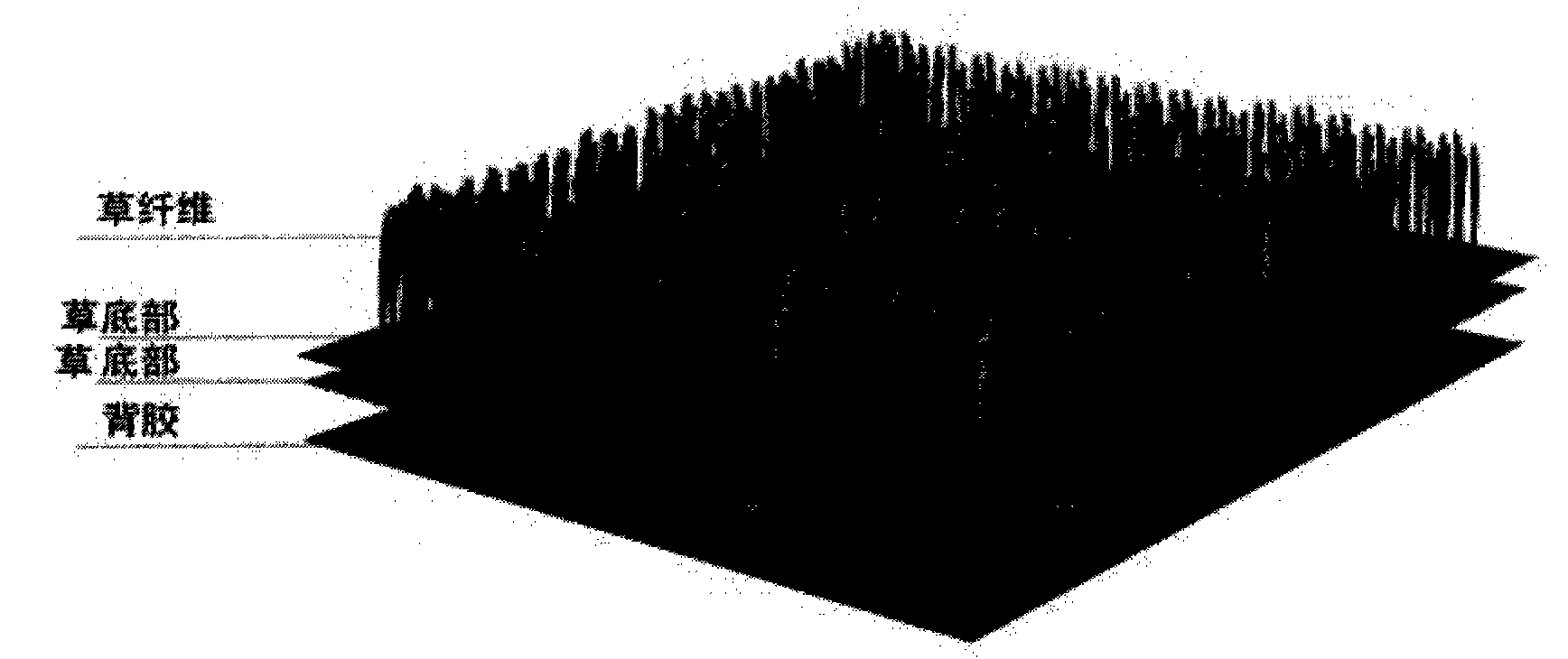

Image

Examples

Embodiment 1

[0027] 100 parts of VAE (ethylene-vinyl acetate copolymer emulsion) (parts by weight, the same below), 150 parts of talcum powder, and 10101 parts of antioxidant.

Embodiment 2

[0029] 100 parts of VAE (ethylene-vinyl acetate copolymer emulsion), 180 parts of ground calcium carbonate, and 10102 parts of antioxidant.

[0030] The manufacturing method of the artificial turf of the present invention will be specifically described below. For the sake of convenience, the grass fiber and grass bottom assembled together will be referred to as turf hereinafter.

[0031] Mix all components of the above adhesive formula in advance to prepare a glue for later use. Subsequently, put the above-mentioned glue into the glue tank, make the turf pass through the upper part of the glue tank at a certain speed for gluing, and the turf after gluing is heat-treated through the hot air box at a certain speed, and the hot air (110 ℃ ~ 150 ℃) Blow to the turf from top to bottom.

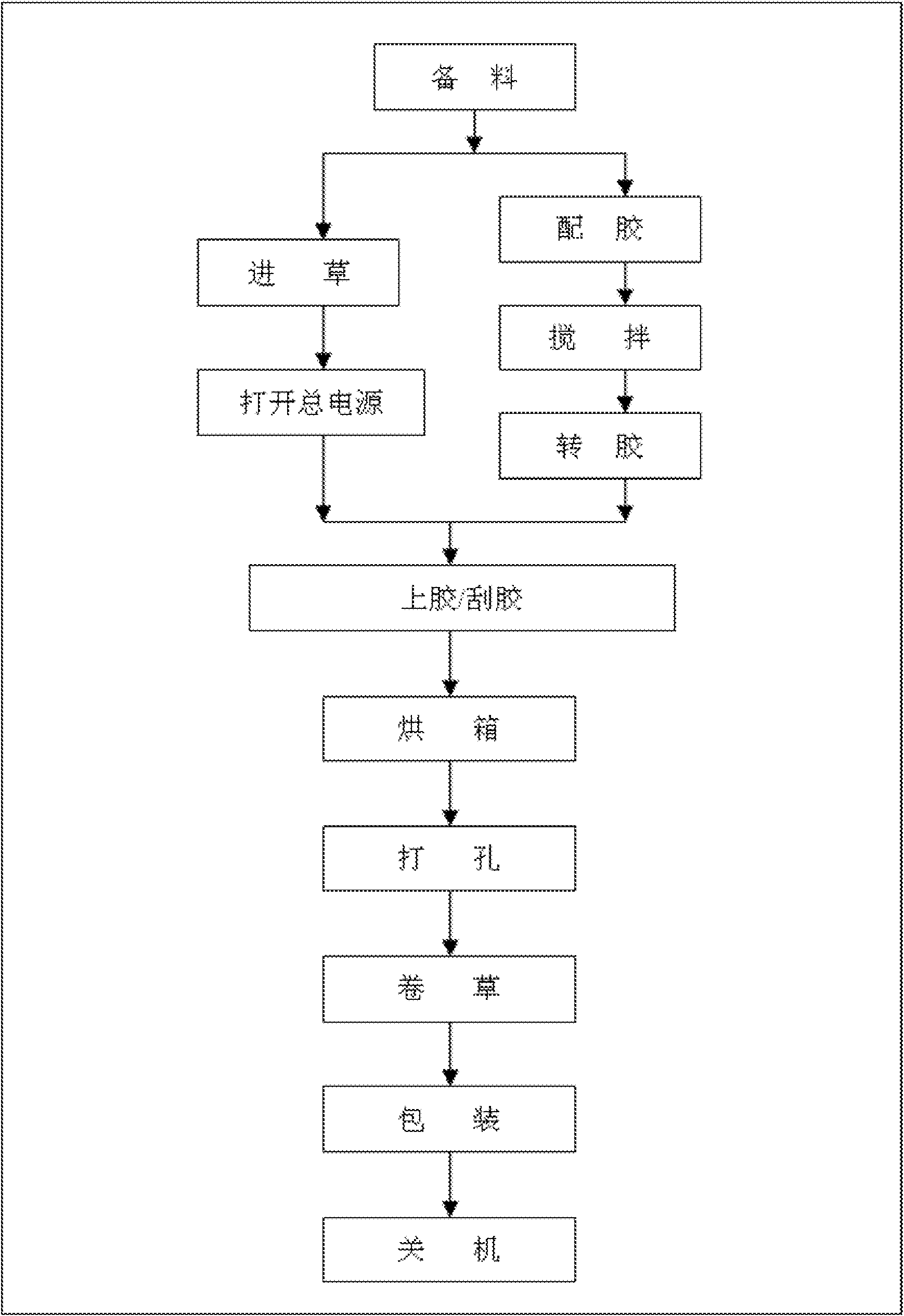

[0032] Such as figure 2 As shown, the specific process steps are as follows:

[0033] 1) Pull the turf to be glued to the grass-feeding position, the joints are stitched neatly and firmly, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com