Nonwoven fabric

A non-woven, weight per unit area technology, applied in non-woven fabrics, textiles and papermaking, etc., can solve problems such as not easy penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

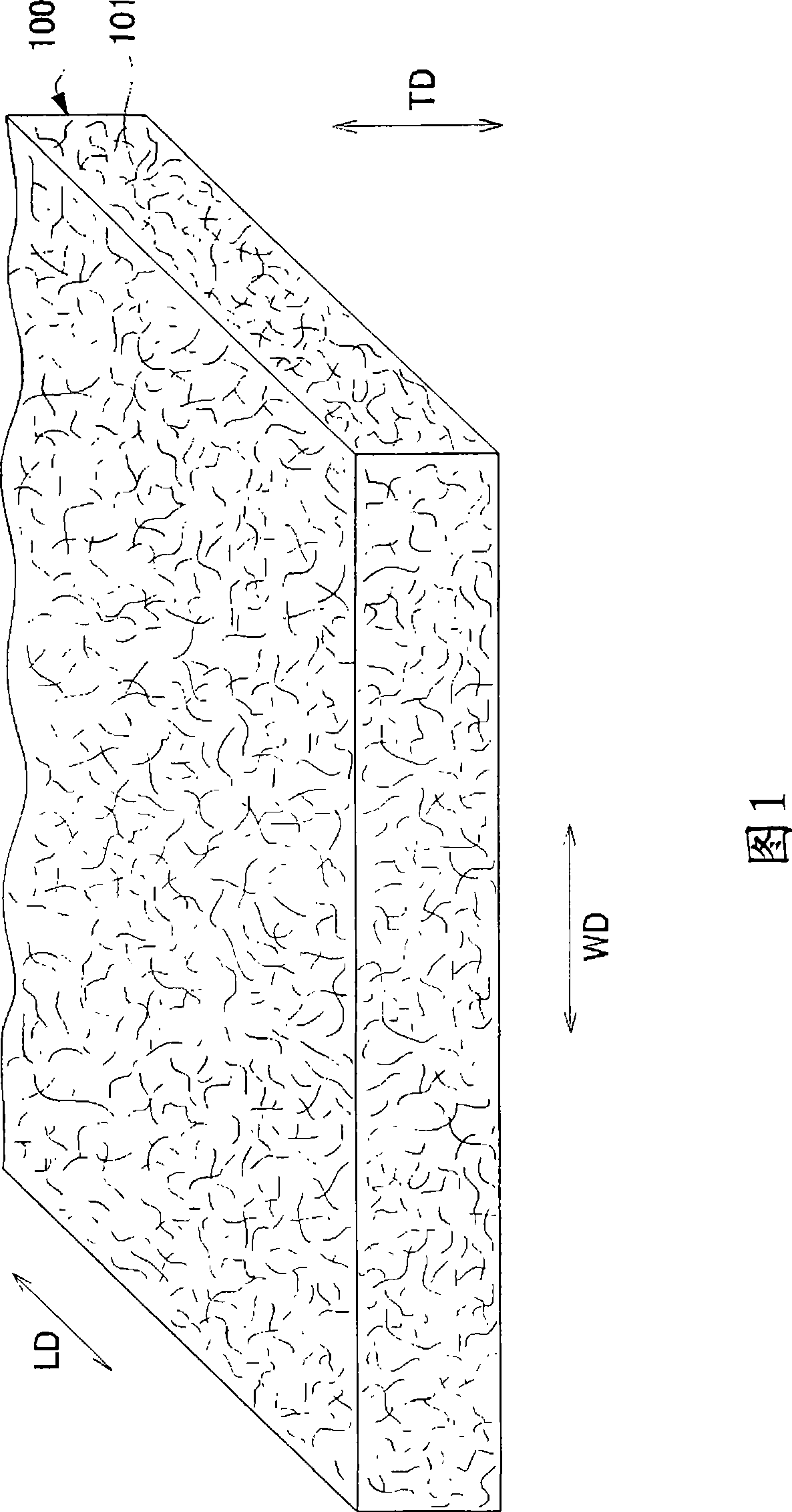

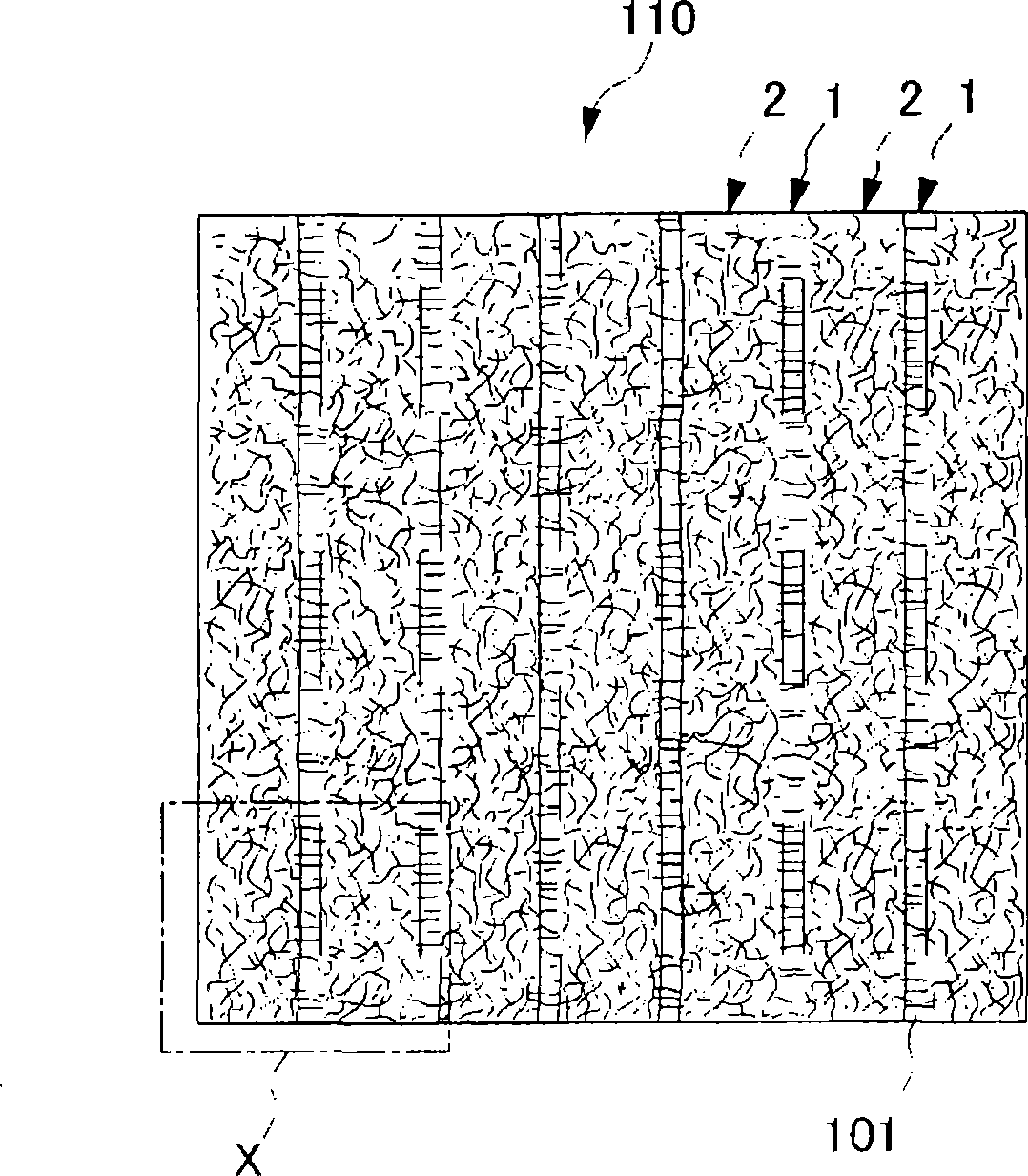

[0055] A first embodiment of the nonwoven fabric of the present invention will be described with reference to FIGS. 1 to 5 .

[0056] The nonwoven fabric 110 of this embodiment is a nonwoven fabric that can be formed by spraying a fluid mainly composed of gas onto the fiber web 100 that is a fiber aggregate. And, it is a convex shape in which a plurality of low basis weight portions formed along the longitudinal direction (LD) as the first direction and a plurality of high basis weight portions formed along the groove portion 1 are formed. Part 2 of the non-woven fabric. In addition, the fiber basis weight of the groove portion 1 is adjusted to be smaller than the fiber basis weight of the convex portion 2 .

[0057] 1-1. Shape

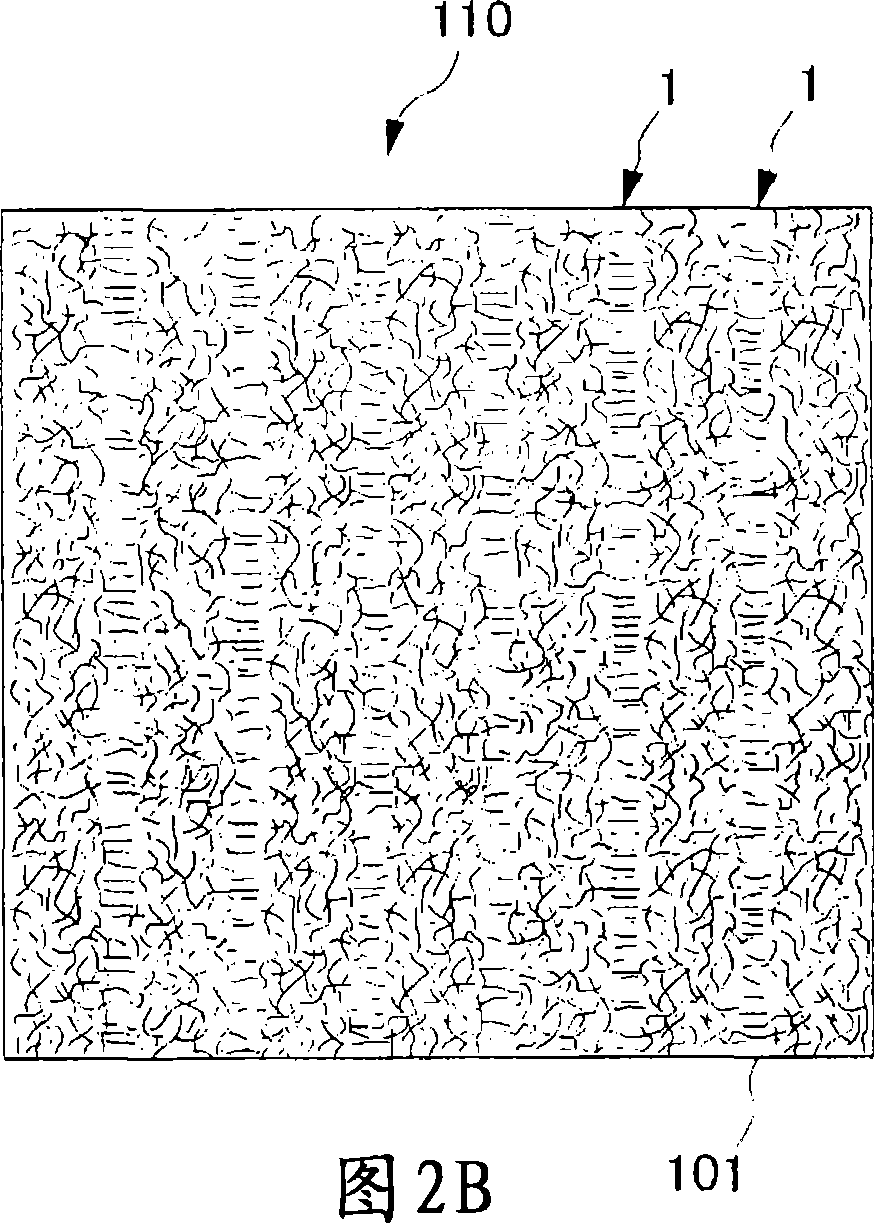

[0058] As shown in FIG. 2(A), FIG. 2(B) and FIG. 3, the nonwoven fabric 110 of this embodiment is a nonwoven fabric in which a plurality of grooves 1 are formed side by side at approximately equal intervals on one side of the nonwoven fabric 110. s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap