Method and apparatus for pre-heating LNG boil-off gas to ambient temperature prior to compression in a reliquefaction system

A technology for reliquefaction and boil-off gas is applied in the field of equipment used to preheat LNG boil-off gas to normal temperature before compression in a reliquefaction system, which can solve problems such as reducing equipment performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

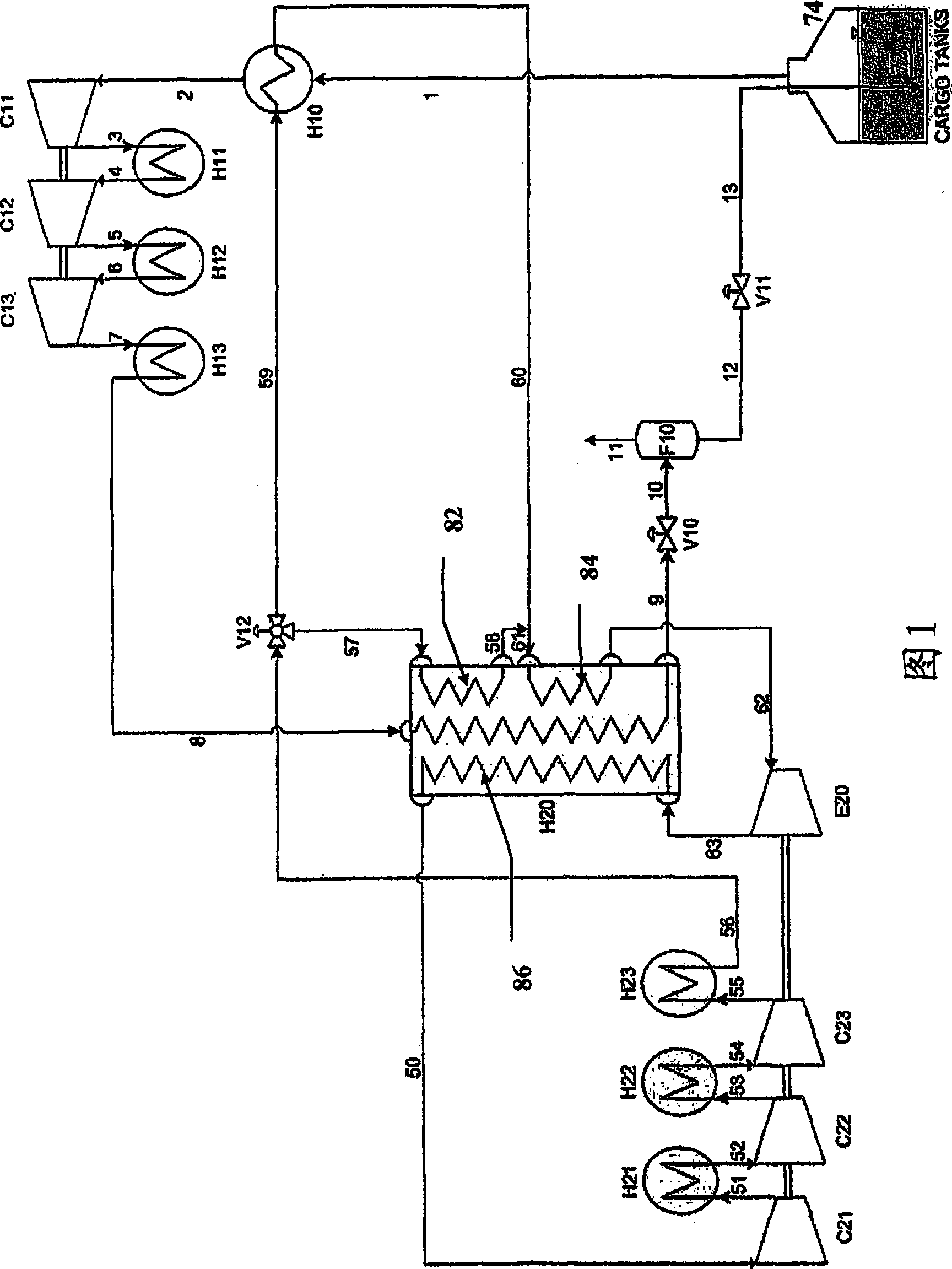

[0015] The present invention will now be described with reference to Figure 1, which shows the novel features of an LNG RS with normal temperature BOG compression.

[0016] The figure schematically shows the shipping compartment 74, which holds a certain amount of LNG72. The BOG evaporated from the LNG enters the pipe 1 connected to the first heat exchanger H10. In this heat exchanger, as described later, BOG is heated to near normal temperature. After this preheating, BOG enters the first-stage BOG compressor C11 via pipe 2. The BOG compressor is shown as three-stage centrifugal compressors C11, C12, C13 connected to each other via pipes 3-7 through intercoolers H11, H12, and aftercoolers H13 as shown in the figure, but other compressor types are also applicable . The preheating ensures that the heat generated by the compression can be dissipated through the cooling water in the intercoolers H11, H12 and the aftercooler H13.

[0017] The pressurized BOG is then provided through p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com