Rotary type electric component

An electrical component, rotary technology, applied in electrical components, circuits, electrical switches, etc., to solve problems such as reduced "click" feeling, difficulty in obtaining a sense of joint, and durability of leaf springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In this embodiment, an encoder switch is exemplified as a rotary electric component, but a varistor which is one type of rotary electric component can also be applied.

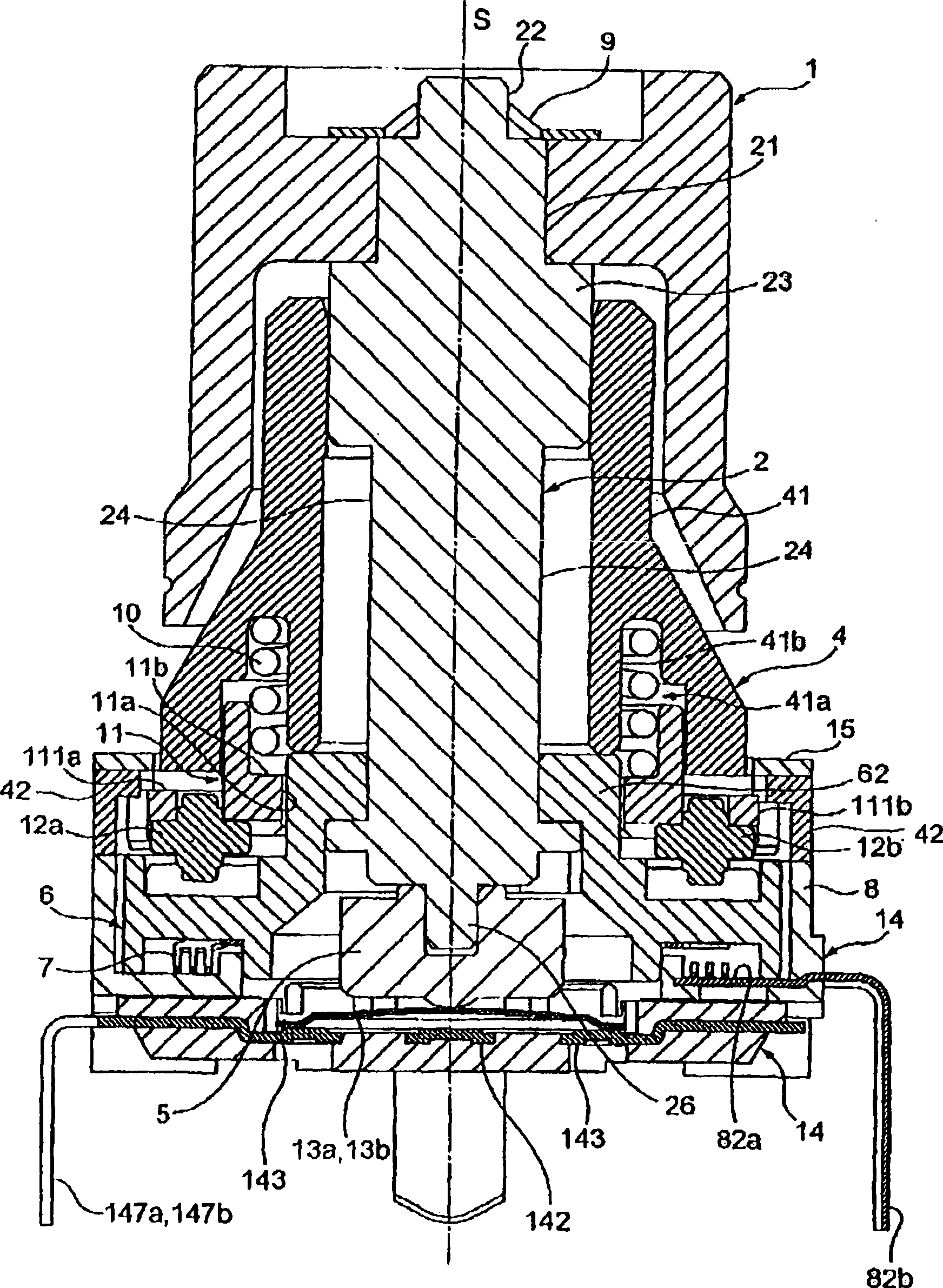

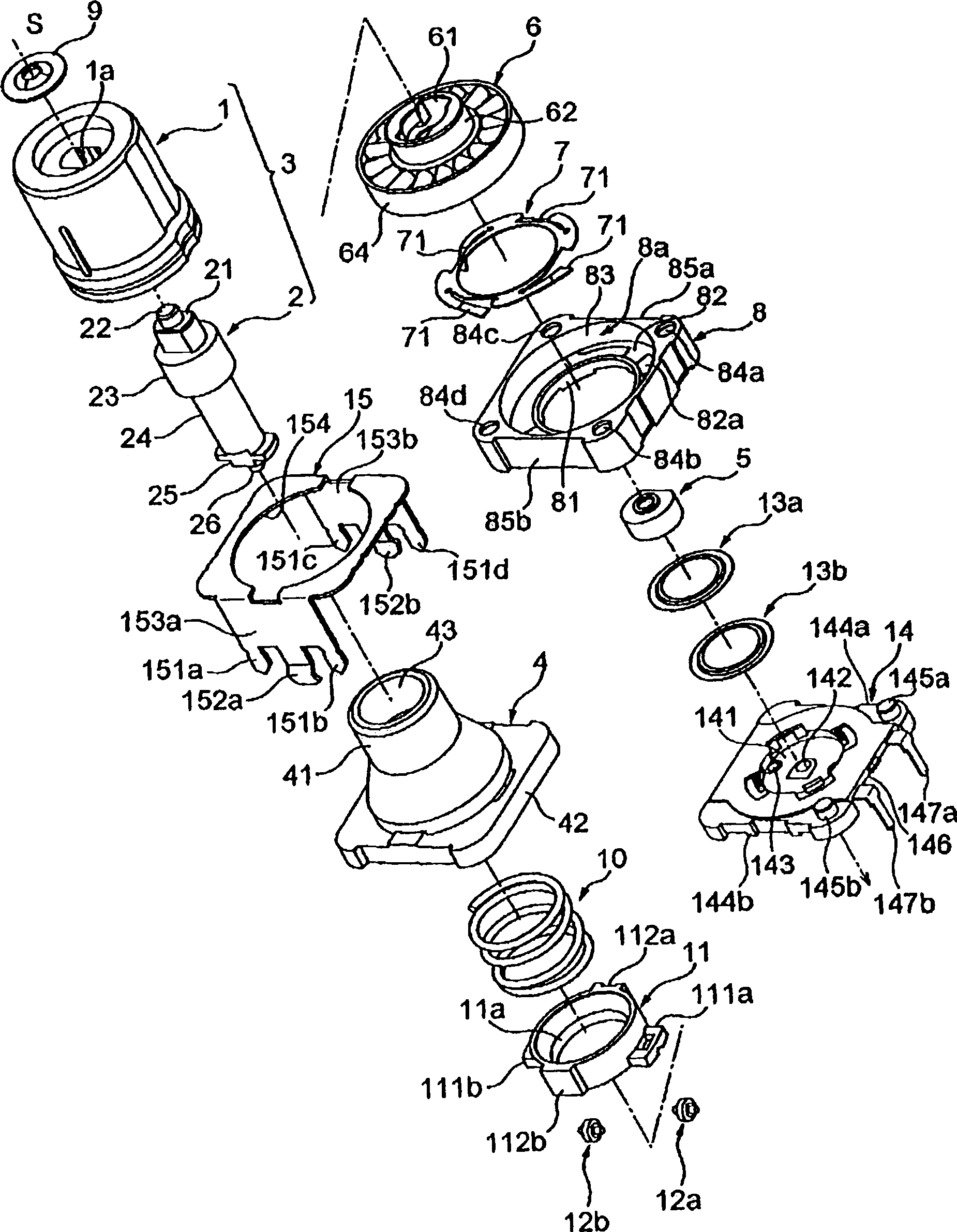

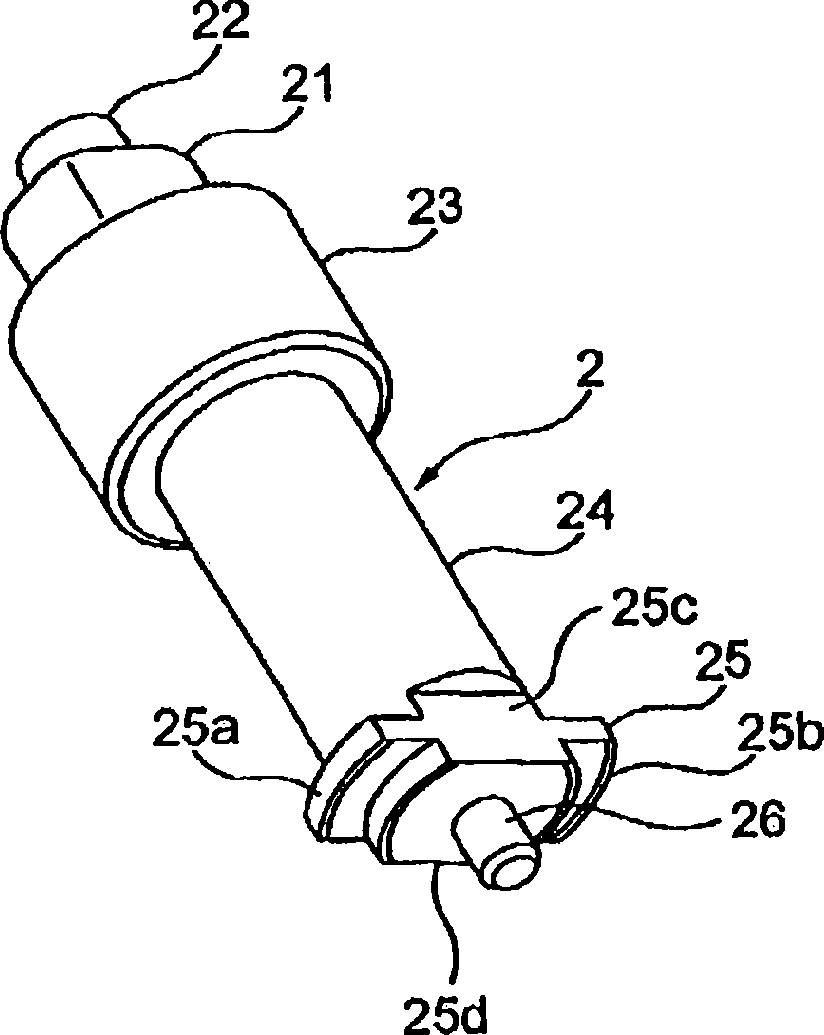

[0037] figure 1 It is a cross-sectional view of a rotary electric component according to an embodiment of the present invention, figure 2 It is an exploded perspective view of the rotary electric component of this embodiment. The operation shaft 3 constituted by the outer shaft 1 and the inner shaft 2 can be supported by a bearing member for rotation and pressing operation. The pressing member 5 is press-fitted and fixed to one end of the inner shaft 2 inserted into the rear side of the bearing member 4 . On the rear surface (the other side) of the rotary member 6 is fixed a sliding member 7 made of an annular metal plate as a sliding contact. The rotating member 6 is held rotatably in a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com