Lifting frame

A technology for transporting and supporting frames, which is applied in the field of lifting and transporting frames, and can solve problems such as large personnel, glass breakage and injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

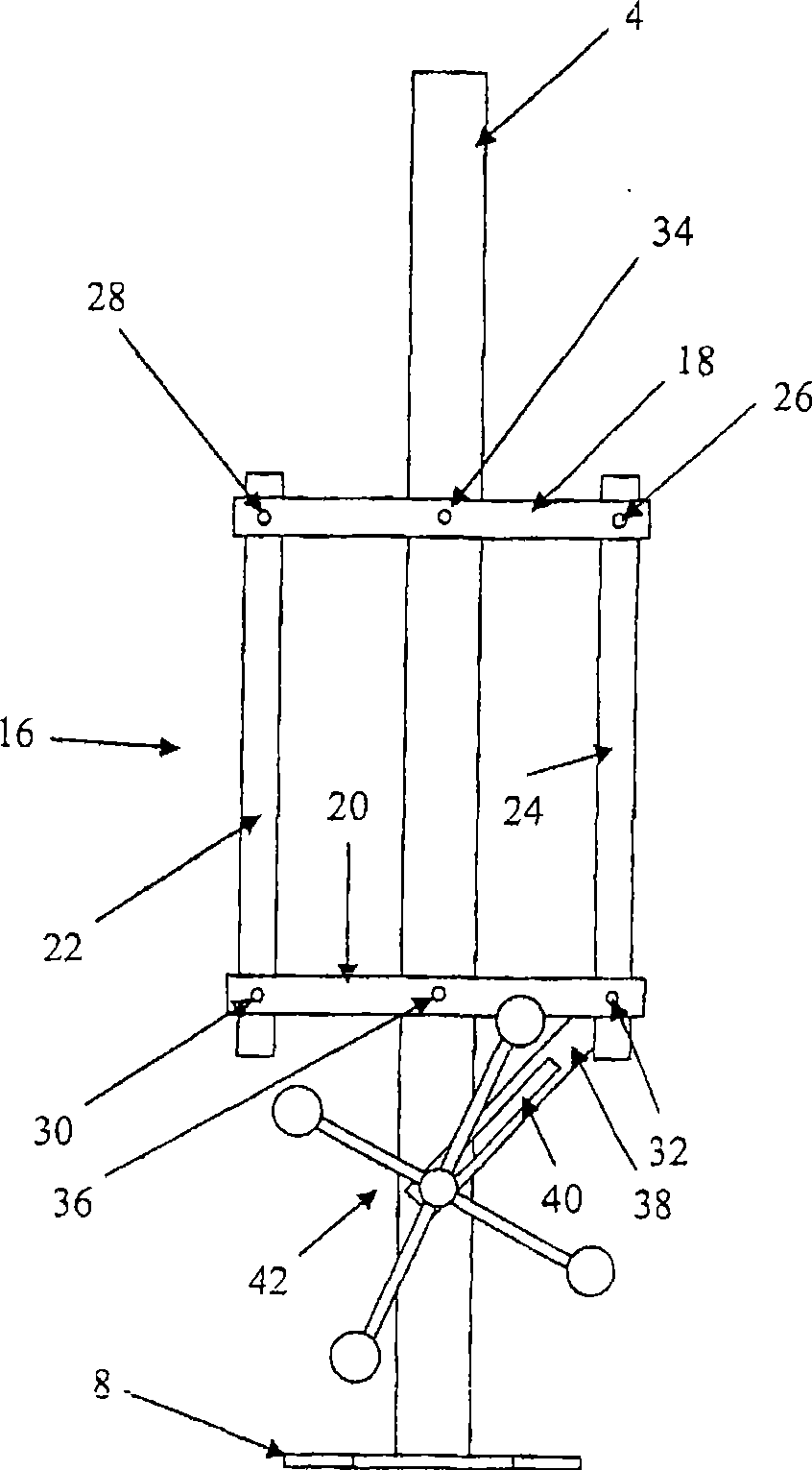

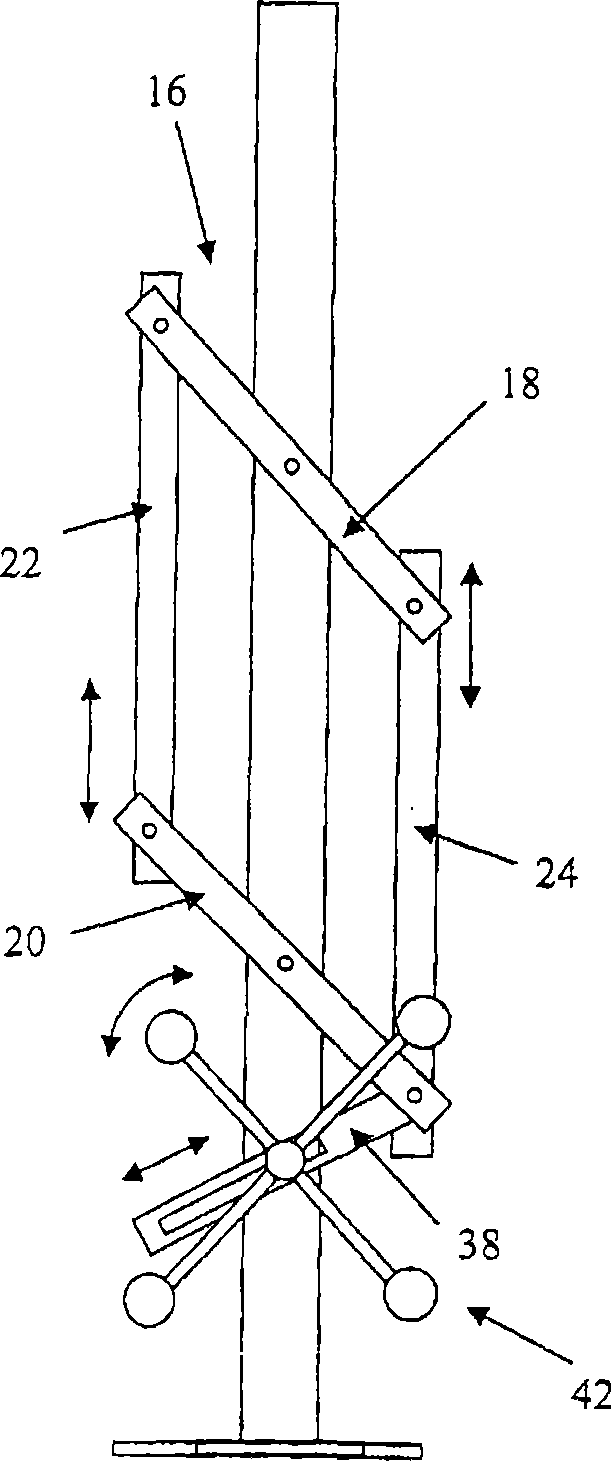

[0068] Stacks of coated glass panels are stacked on a stacking rack with the coated side facing the uprights of the stacking rack. The base of the stacking rack has a narrower width than the main faces of the stacks of glass panes, so that each stack of glass panes protrudes beyond the base of the stacking rack. Lift the stack of glass panels from the ground. adopted as Figure 12 A lifting frame of the type shown is used to rotate the stack of glass sheets 180 degrees about a vertical axis, ie to move the stack of glass sheets to another stacking rack so that the uncoated side of the glass sheets faces the uprights of the stacking rack.

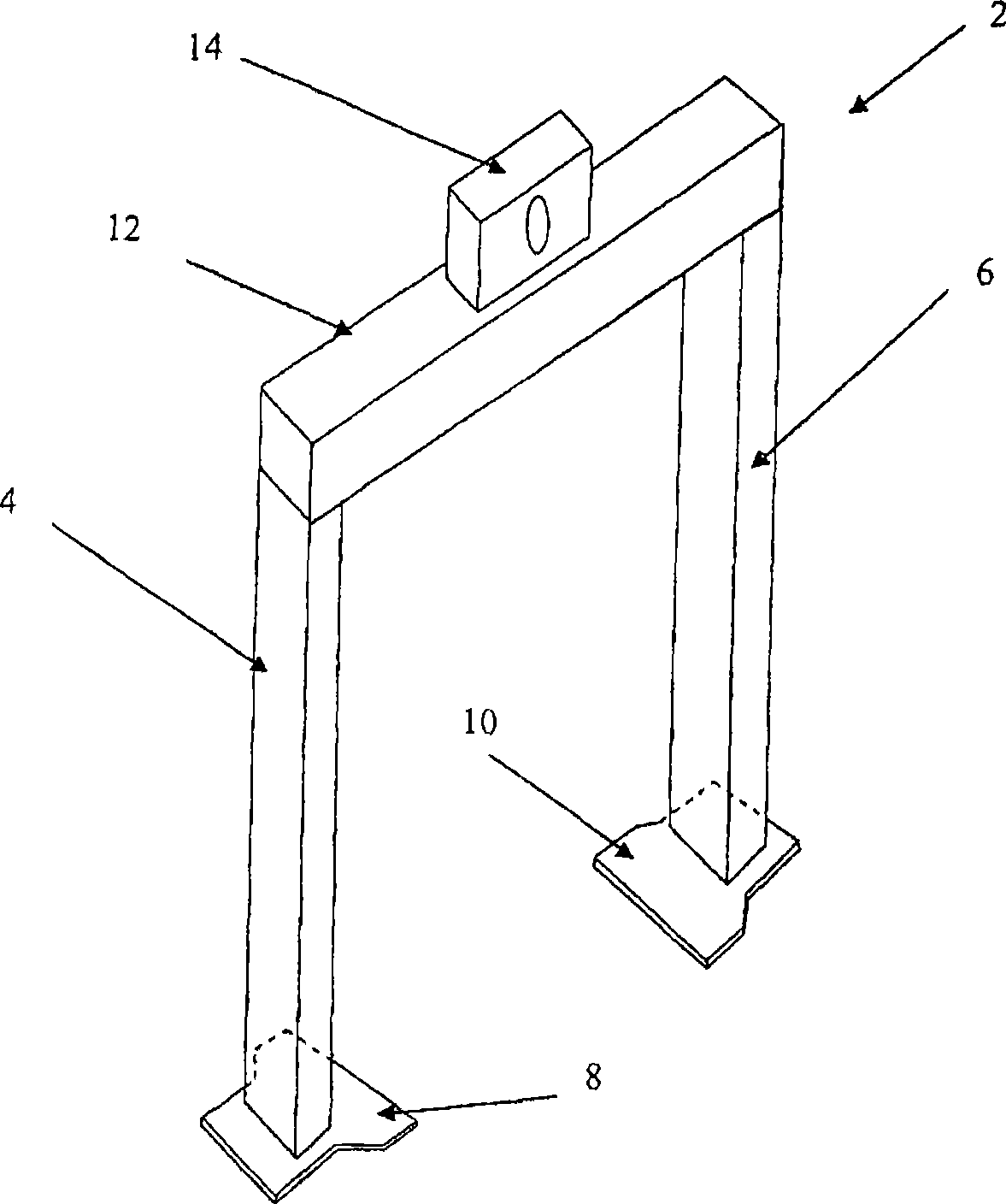

[0069] The lifting frame employed has a first leg and a second leg. The first foot is connected to the bottom of the first leg and the second foot is connected to the bottom of the second leg. The tops of the two legs are connected by a cross member. A lifting chassis is attached to the cross member to allow movement of the lifting frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com